Industry information

Company News

- Aluminum curtain wall: a fashionable element in urban architecture

- Aluminum Ceiling: Creating a New Style of Modern Home Furnishings

- Aluminum veneer, the 'invisible hero' in modern architecture

- Aluminum honeycomb panel: a perfect combination of lightweight and sturdy

- Aluminum veneer: the 'hermit hero' in architecture

Industry dynamics

- The mystery of honeycomb aluminum plate: the secret behind its lightness

- Aluminum veneer: Improving the durability and reliability of buildings

- Production and processing technology, performance, and quality assurance of 1.5mm aluminum veneer

- Honeycomb aluminum plate: What secrets are hidden behind its lightweight design?

- What are the impacts of the design and material selection of curtain wall aluminum veneer on building energy efficiency?

Frequently asked questions

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Can aluminum veneer achieve customized design?

- Is the surface treatment of aluminum veneer durable?

- How does the plasticity of aluminum veneer affect building comfort?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and equipment maintenance of aluminum veneer and measures to improve production efficiency

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 18:58:59

- Click:0

Aluminum veneerAs a new type of building material, its production process and equipment maintenance are also important factors affecting its production efficiency and product quality. Below, we will provide a detailed introduction to the production process and equipment maintenance of aluminum veneer, as well as measures to improve production efficiency.

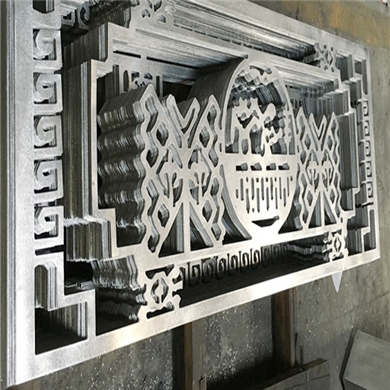

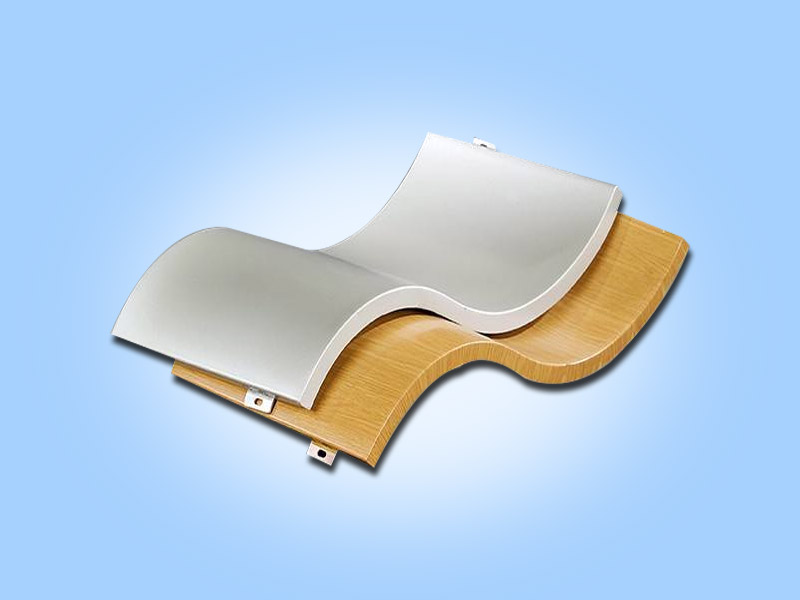

The production process of aluminum veneer includes raw material procurement, melting, rolling, surface treatment and other links. Raw material procurement is the foundation for ensuring product quality, and it is necessary to choose high-quality raw material suppliers; Smelting is the process of heating aluminum to a certain temperature to melt it, and then rolling it into shape through a mold; Surface treatment is the process of spraying, anodizing, and other treatments on the rolled aluminum veneer to improve the product's aesthetics and corrosion resistance. By optimizing the production process, production efficiency and product quality can be improved.

The maintenance of aluminum veneer equipment is also an important factor in ensuring production efficiency and product quality. For example, it is necessary to regularly inspect and maintain the mechanical equipment on the production line to ensure the normal operation of the equipment; It is necessary to clean the spraying equipment and replace components such as nozzles to ensure the quality of spraying; It is necessary to clean and replace the electrolyte and other components of the anodizing equipment to ensure the quality of anodizing. By strengthening equipment maintenance, the service life of equipment can be extended, production efficiency and product quality can be improved.

The measures to improve production efficiency are also one of the issues that aluminum veneer production enterprises need to pay attention to. For example, by introducing advanced production equipment and technology, production efficiency and product quality can be improved; By optimizing the production process flow, reducing production links and waste rates, and improving production efficiency and product quality; By strengthening employee training and management, improving employee skills and work efficiency, production efficiency can be enhanced.

The production process and equipment maintenance of aluminum veneer, as well as measures to improve production efficiency, are important factors affecting its production efficiency and product quality. By continuously innovating and applying new technologies, strengthening equipment maintenance and management, and optimizing production processes, the market competitiveness and market share of aluminum veneer can be further improved, achieving maximum investment return. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

- previous page:What are the manufacturers of aluminum veneer?

- Next page:What are the production equipment for aluminum veneer?

Customer service QQ

Customer service QQ