Industry information

Company News

- Aluminum veneer: the "silver coat" of modern architecture

- The 'fresh little expert' in the aluminum ceiling industry: a new proposition for creating fashionable spaces

- Customized aluminum veneer: an artistic journey to create personalized spaces

- Aluminum curtain wall: the fashionable "coat" of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer customization, creating personalized spatial aesthetics

- The secret of aluminum veneer: the story behind its lightness

- Design and Construction Practice of Aluminum Single Panel for Irregular Wall

- The application prospects of fluorocarbon coatings in the construction and decoration industry

- Cost control method for imitation wood grain aluminum veneer

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Is the surface treatment of aluminum veneer durable?

- What is the manufacturing process of aluminum veneer?

- Can aluminum veneer be used in the design of building arch bridges?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

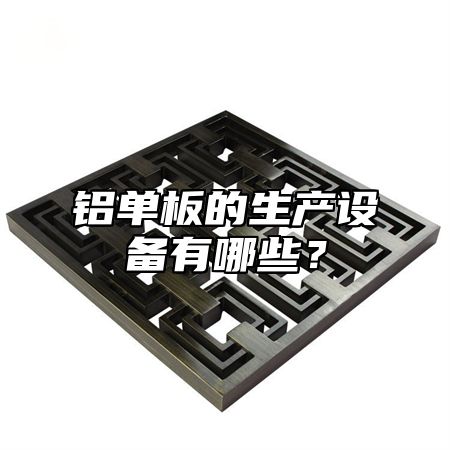

What are the production equipment for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 25, 2025 16:17:00

- Click:0

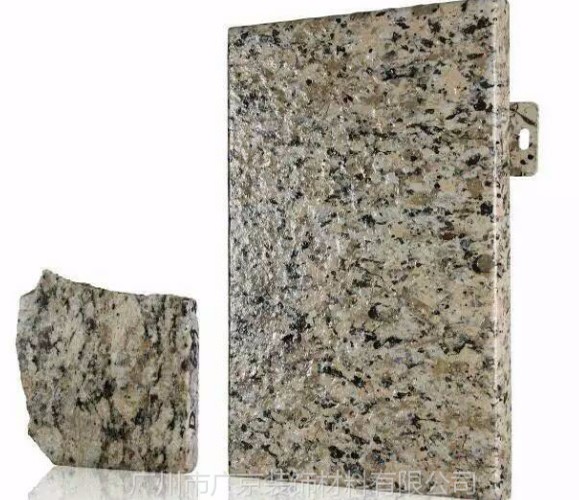

Aluminum veneerAs a common building material, its production equipment is also one of the important factors affecting its quality and efficiency. Below, we will provide a detailed introduction to the production equipment and classification of aluminum veneer.

1. Kaiping machine

Kaiping machine is one of the most basic equipment in aluminum veneer production, mainly used for processing aluminum coil materials such as Kaiping, shearing, and bending. Kaiping machines can be divided into two types based on their processing methods: mechanical Kaiping machines and hydraulic Kaiping machines.

1. CNC punch press

CNC punching machine is a high-precision and high-efficiency aluminum veneer processing equipment, mainly used for punching, cutting, bending and other processing operations of various shapes on aluminum veneer. CNC punching machines can be customized in design and manufacturing according to different processing and process requirements, improving production efficiency and product quality.

1. Rolling mill

A embossing machine is a device used for processing patterns on the surface of aluminum veneer, mainly for embossing, drawing, and spraying various patterns on aluminum veneer. The embossing machine can be customized in design and manufacturing according to different pattern and process requirements, improving the decorative effect and aesthetics of the product.

1. Spray line

Spray line is a device used for surface coating treatment of aluminum veneer, mainly used for spraying various colors and coatings on aluminum veneer. Spray lines can be customized and manufactured according to different coating and process requirements to improve product surface quality and durability.

1. Laser cutting machine

Laser cutting machine is a high-precision and high-efficiency aluminum veneer processing equipment, mainly used for cutting and carving various shapes on aluminum veneer. Laser cutting machines can be customized and manufactured according to different processing and process requirements, improving production efficiency and product quality.

The production equipment for aluminum veneer includes various types such as leveling machines, CNC punching machines, embossing machines, spraying lines, laser cutting machines, etc. The selection and use of these devices need to be combined with specific production processes and product requirements to ensure optimal quality and efficiency of aluminum veneer. We also need to strengthen technological innovation and research and development efforts, constantly innovate and contribute to the sustainable development of the construction industry.

Customer service QQ

Customer service QQ