Industry information

Company News

- Aluminum curtain wall: the fashionable coat of modern architecture

- Honeycomb aluminum plate: the secret power behind lightness

- Aluminum veneer customization, creating an exclusive style space

- Aluminum veneer customization, creating personalized space and new fashion

- The charm of honeycomb aluminum plate: the perfect combination of lightness and sturdiness

Industry dynamics

- Aluminum veneer customization, creating exclusive space aesthetics

- What is the impact of the thickness of aluminum veneer on its performance?

- The secret behind aluminum ceiling: the perfect fusion of lightness and aesthetics

- How to choose suitable baked paint ceiling aluminum veneer products

- Aluminum veneer: bringing unique texture and luster to buildings

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- How can aluminum veneer improve the appearance of buildings?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- How does the plasticity of aluminum veneer affect building comfort?

- Can aluminum veneer achieve customized design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: What secrets are hidden behind its lightweight design?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-21 22:23:01

- Click:0

Ladies and gentlemen, today we will talk about a material that sounds a bit high-end - honeycomb aluminum plate. Does it sound high-tech? It is right beside us, playing a significant role. What is honeycomb aluminum plate? Why is it so popular? Listen to me slowly.

Let's talk about the origin of honeycomb aluminum sheet. It is said that this magical thing originated during World War II, when German engineers invented honeycomb structures to create a lightweight and sturdy aircraft structure. Later on, this structure was gradually applied in fields such as automobiles, construction, and electronic devices, and honeycomb aluminum panels also emerged.

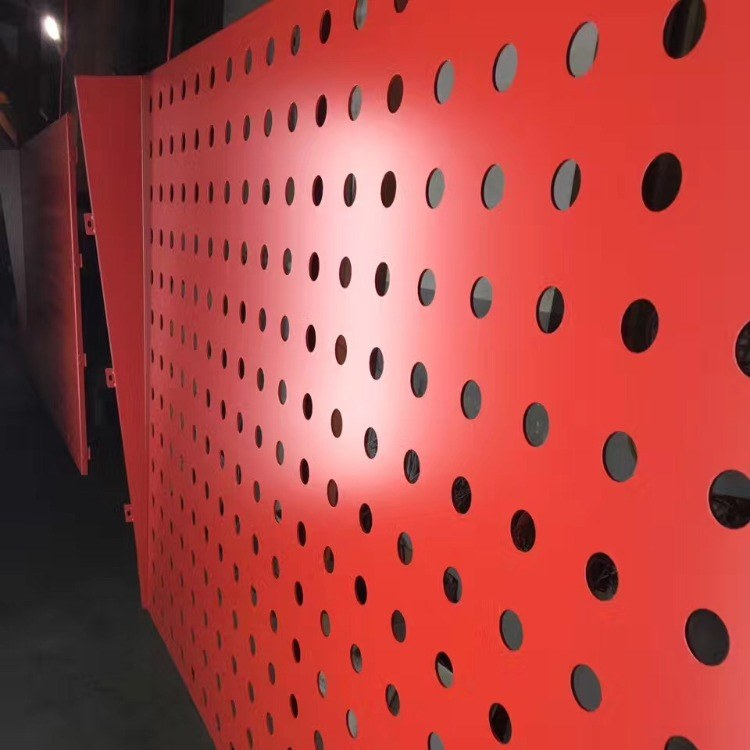

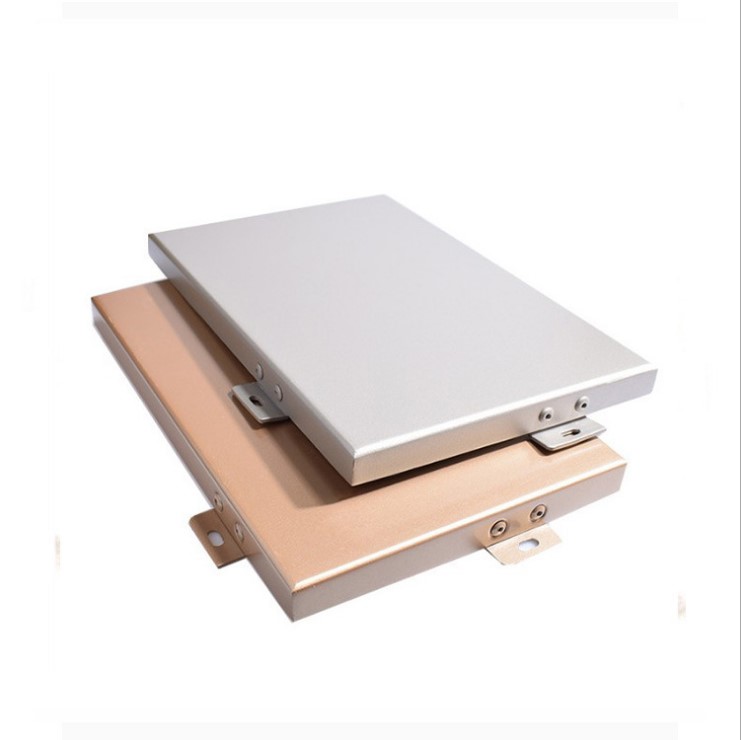

The name "honeycomb aluminum plate" gives a sense of being "high-end". What exactly does it look like? Honeycomb aluminum plate is composed of aluminum honeycomb core and aluminum plate composite. The honeycomb core is like a honeycomb, with many interconnected hexagonal holes that make the honeycomb aluminum plate both lightweight and sturdy.

The lightness of honeycomb aluminum plate is simply unbelievable. Its density is only about 1/5 of steel, but its weight is almost the same. This means that under the same volume, honeycomb aluminum plates are lighter in weight. Believe it or not, look at those racing cars and airplanes, they all use honeycomb aluminum panels as lightweight materials.

Don't think that honeycomb aluminum plate is just lightweight, its strength is also considerable. The honeycomb structure has excellent impact resistance, and even under external forces, the honeycomb aluminum plate can quickly recover to its original state. This makes honeycomb aluminum panels widely used in the field of construction, such as building templates, roofs, walls, etc.

What are the advantages of honeycomb aluminum panels? Let me list a few highlights for you:

1. Lightweight: Lightweight design reduces the weight of equipment, buildings, etc.

2. Sturdy: The honeycomb structure has excellent impact resistance and is not easily deformed.

3. Sound insulation: Honeycomb aluminum plate has good sound insulation effect, which can effectively reduce noise.

4. Thermal insulation: Honeycomb aluminum plate has excellent thermal insulation performance and is suitable for thermal insulation materials.

5. Corrosion resistance: Aluminum materials have good corrosion resistance and extend their service life.

6. Aesthetics: The honeycomb aluminum plate has a smooth surface and good decorative effect.

Honeycomb aluminum plates also have their drawbacks. The price is relatively high and the processing difficulty is high. But in practical applications, the advantages of honeycomb aluminum panels far outweigh these disadvantages.

What are the applications of honeycomb aluminum panels in? Let me give you a few examples:

1. Aerospace: Lightweight design of spacecraft such as airplanes and rockets.

2. Automotive manufacturing: lightweighting of components such as car bodies and engines.

3. In the field of architecture: building templates, roofs, walls, etc.

4. Electronic devices: heat dissipation for electronic products such as mobile phones and computers.

5. Transportation: Lightweight design of transportation vehicles such as trains and subways.

Having said so much, you may still be thinking: Can only professionals handle honeycomb aluminum panels? The application of honeycomb aluminum plate is becoming increasingly widespread, and ordinary people can also come into contact with it. The laptops we usually use may use honeycomb aluminum panels as heat dissipation materials.

Honeycomb aluminum plate, as a lightweight, sturdy, and multifunctional new material, is gradually entering our lives. Perhaps in the near future, we will see more application cases of honeycomb aluminum sheets. Hey guys, what other wonderful application scenarios do you think honeycomb aluminum panels have? Come and share in the comment section!

Customer service QQ

Customer service QQ