Industry information

Company News

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum ceiling decoration is a new trend, both beautiful and practical!

- Aluminum veneer: the beauty of industry, simple yet not simple

- Aluminum veneer customization, creating a new proposition for personalized space!

- Aluminum curtain wall, the new darling of architectural aesthetics

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Design and construction techniques sharing of curtain wall aluminum square tube

- Aluminum veneer customization makes buildings more environmentally friendly and sustainable

- What is the dustproof performance of fluorocarbon aluminum veneer?

- Aluminum veneer customization, creating personalized space art

Frequently asked questions

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

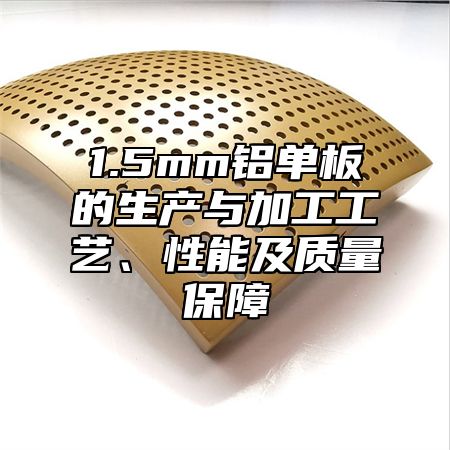

Production and processing technology, performance, and quality assurance of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 14, 2025 21:00:40

- Click:0

1.5mmAluminum veneerAs a lightweight and high-strength building material, its production and processing technology, performance, and quality assurance are important factors in ensuring its quality and effectiveness. Let's learn about the production and processing technology, performance, and quality assurance of 1.5mm aluminum veneer together.

The production and processing technology of 1.5mm aluminum veneer mainly includes raw material procurement, melting, rolling, punching and other links. In terms of raw material procurement, it is necessary to choose high-quality aluminum alloy materials to ensure the quality and performance of 1.5mm aluminum veneer. In terms of smelting, advanced smelting equipment and technology are needed to ensure the purity and uniformity of aluminum materials. In terms of rolling, advanced equipment such as high-speed wire cutting and CNC machine tools are needed to ensure the dimensional accuracy and surface smoothness of aluminum veneer. In terms of punching, advanced punching equipment and technology are needed to ensure the accuracy of the hole size and shape of aluminum veneer.

The performance of 1.5mm aluminum veneer mainly includes strength, corrosion resistance, breathability, thermal insulation, sound insulation, and other aspects. In terms of strength, 1.5mm aluminum veneer has high tensile strength and yield strength, and can withstand large loads and deformations. In terms of corrosion resistance, 1.5mm aluminum veneer has good oxidation resistance and corrosion resistance, and can maintain stable performance in various harsh environments. In terms of breathability, thermal insulation, and sound insulation, 1.5mm aluminum veneer can be treated and designed differently according to customer needs to meet different usage scenarios and requirements.

The quality assurance of 1.5mm aluminum veneer mainly includes strict quality control and testing system. In the production process, strict quality control and testing are required for each link to ensure that the quality of aluminum veneer meets the standard requirements. Before leaving the factory, a comprehensive inspection and testing of each batch of aluminum veneer is required to ensure its stable and reliable quality. We also need to establish a comprehensive after-sales service system to provide customers with timely and professional technical support and services.

The production and processing technology, performance, and quality assurance of 1.5mm aluminum veneer are important factors in ensuring its quality and effectiveness. Only by fully understanding these factors can we better unleash the unique charm and value of 1.5mm aluminum veneer, bringing more convenience and beauty to people's lives and work.

Customer service QQ

Customer service QQ