Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Customized aluminum veneer to make buildings more in line with people's aesthetic trends

- Aluminum veneer customization: an artistic journey to create personalized spaces

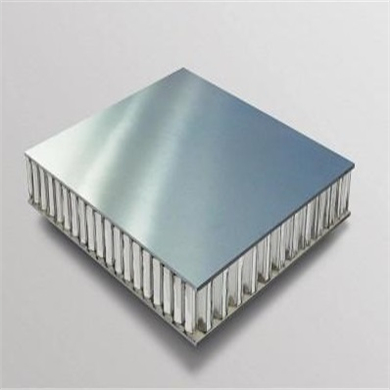

- The charm of honeycomb aluminum plate: the perfect combination of lightness and sturdiness

- Aluminum veneer: understated luxury in modern architecture

Industry dynamics

- Honeycomb aluminum plate: a lightweight choice, the new favorite of future building materials?

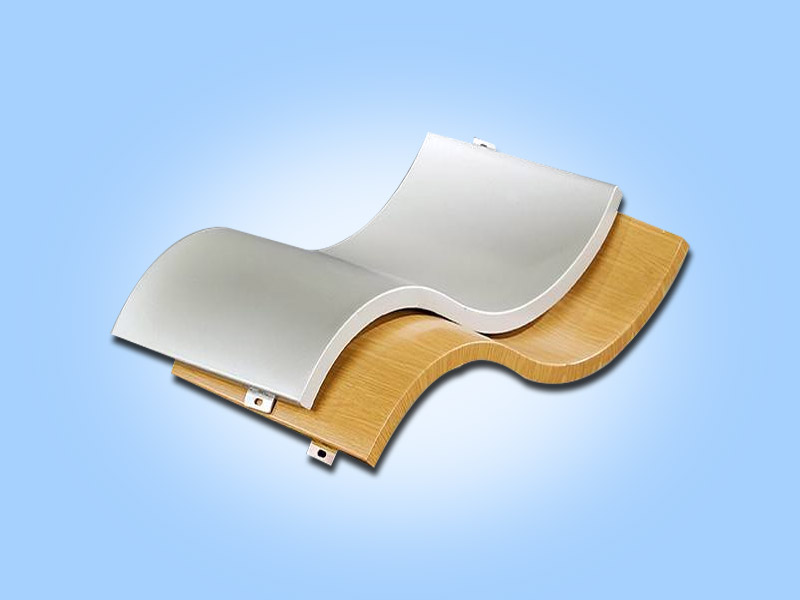

- Installation method and precautions for curved ceiling aluminum veneer

- Aluminum ceiling, a fresh choice for creating home spaces!

- OMG! These aluminum veneer creative designs are simply breathtaking!

- Aluminum curtain wall: the beauty of architecture, the light of innovation

Frequently asked questions

- How does the plasticity of aluminum veneer affect building comfort?

- What is the manufacturing process of aluminum veneer?

- Has the production process of aluminum veneer reduced energy consumption?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Can aluminum veneer achieve customized design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

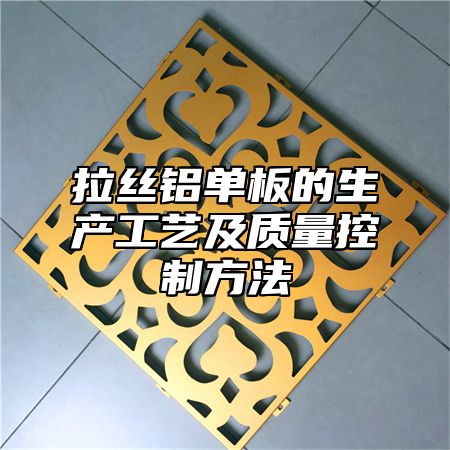

Production process and quality control method of brushed aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 16, 2025 00:27:50

- Click:0

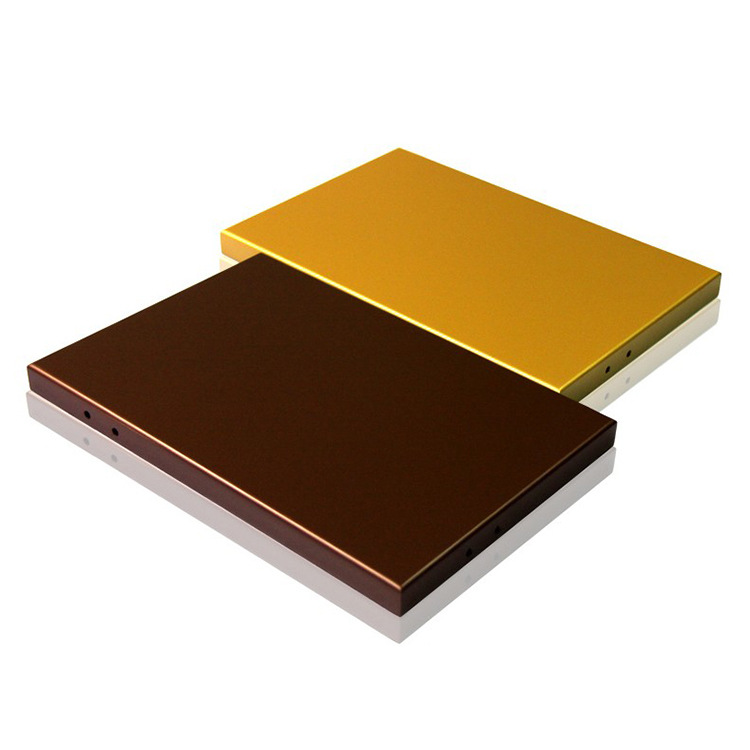

wire drawingAluminum veneerIt is a high-end building material that presents a texture effect similar to silk on its surface and has high decorative value. In order to ensure the quality and aesthetics of brushed aluminum veneer, strict production processes and quality control methods are required.

1、 Production process

1. Raw material procurement: The main raw material for brushed aluminum veneer is high-strength aluminum alloy sheet, which needs to be purchased from regular suppliers and undergo quality testing.

2. Cutting and processing: Cut and process the raw materials according to the design requirements to obtain the required aluminum plate size and shape. This step requires the use of high-precision cutting equipment to ensure the accuracy and surface smoothness of the aluminum plate.

3. Rolling processing: Place the cut aluminum plate into a rolling mill for rolling processing to achieve the desired thickness and width. This step requires attention to controlling the tension and speed of the rolling mill to ensure uniform thickness of the aluminum plate.

4. Wire drawing processing: Place the rolled aluminum plate into a wire drawing machine for wire drawing processing, so that its surface presents a texture effect similar to silk. This step requires controlling the tension and speed of the wire drawing machine to ensure the uniformity and consistency of the wire drawing effect.

2、 Quality control methods

1. Raw material testing: When purchasing raw materials, it is necessary to conduct quality testing on each batch of raw materials, including chemical composition, mechanical properties, and other aspects. Only raw materials that meet the requirements can be used for production.

2. Production process monitoring: During the production process, it is necessary to monitor every step, including cutting, rolling, drawing and other processes. By monitoring the production process, problems can be identified in a timely manner and measures can be taken to solve them.

3. Finished product testing: Before leaving the factory, each batch of products needs to be tested, including dimensional accuracy, surface smoothness, texture effect, and other aspects. Only products that have passed the inspection can be sold after leaving the factory.

3、 Precautions

When using brushed aluminum veneer, the following points should also be noted:

1. Avoid prolonged exposure to sunlight or rainy or snowy weather to avoid affecting its lifespan and aesthetics.

2. Avoid contact with acidic and alkaline solutions to prevent corrosion of the aluminum plate surface.

3. Avoid using hard objects to scratch the surface of the aluminum plate to avoid damaging the surface texture effect.

As a high-end building material, the production process and quality control methods of brushed aluminum veneer need to be strictly controlled. Only through scientific production processes and strict quality control methods can the quality and aesthetics of brushed aluminum veneer be guaranteed.

Customer service QQ

Customer service QQ