Industry information

Company News

- Aluminum veneer: an environmentally friendly and sustainable building choice

- Aluminum veneer customization: the art of creating personalized spaces

- Aluminum ceiling, creating a new trend of modern space

- Aluminum veneer: lightweight building material, the new favorite of modern home furnishings

- Aluminum ceiling, creating a home that combines fashion and practicality

Industry dynamics

- What are the improvements in the application of aluminum veneer in the construction industry?

- Aluminum veneer customization: personalized space, separated by one board

- Environmental certification and qualification of 3mm aluminum veneer

- Aesthetic and creative design of painted wall aluminum veneer

- Aluminum honeycomb panel: a perfect combination of lightweight and sturdy

Frequently asked questions

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- Is the surface treatment of aluminum veneer durable?

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

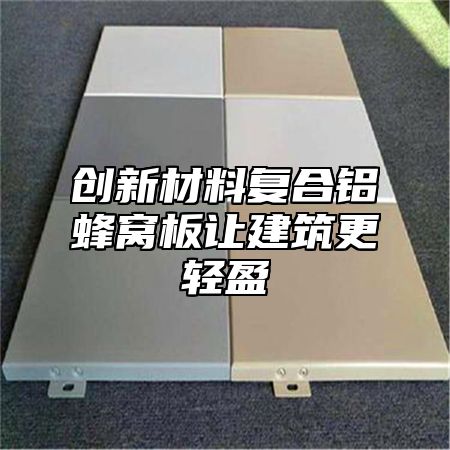

Innovative material composite aluminum honeycomb panel makes buildings lighter

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 17:52:14

- Click:0

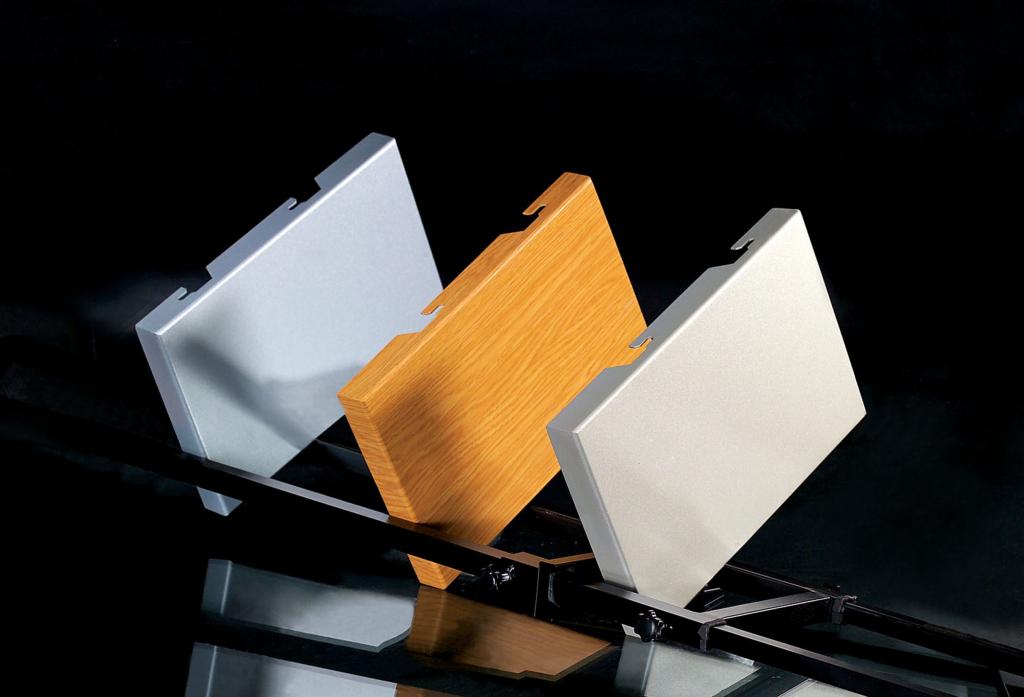

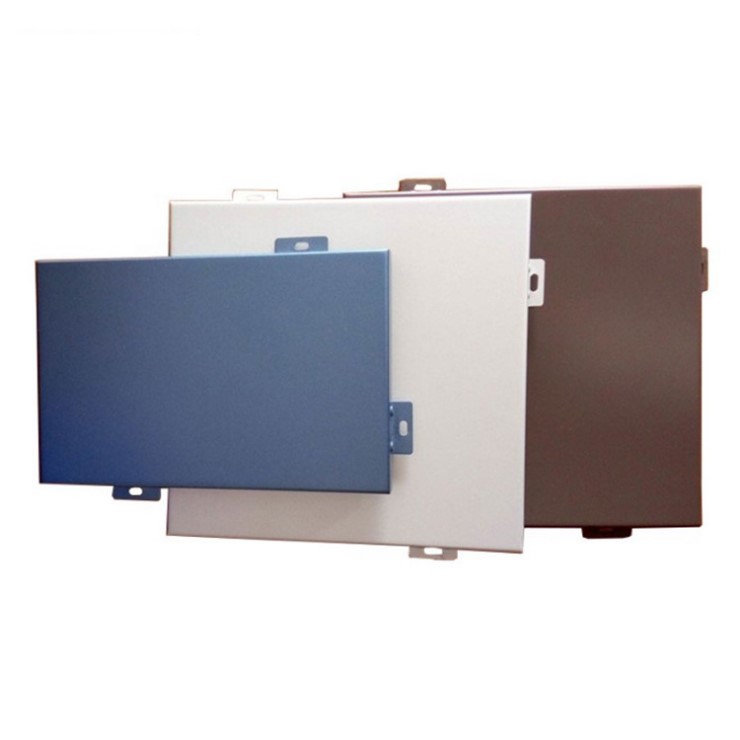

With the continuous improvement of people's requirements for building appearance and performance, traditional building materials can no longer meet people's needs. The application of innovative materials has become a major trend in the construction industry. Composite aluminum honeycomb panel, as a new type of building material, has been widely used in the construction industry due to its lightweight, high strength, and corrosion resistance. This article will provide a detailed introduction to the characteristics and applications of composite aluminum honeycomb panels from the following aspects.

1、 Characteristics

1. Lightweight: The composite aluminum honeycomb panel adopts a lightweight design, which is about 30%~50% lighter than traditional building materials. It can greatly reduce the weight of buildings and lower their energy consumption.

2. High strength: Composite aluminum honeycomb panels have high strength and rigidity, and can withstand large loads and external forces, ensuring the safety and stability of buildings.

3. Corrosion resistance: The surface of the composite aluminum honeycomb panel is anodized to form a dense oxide film, which has strong corrosion resistance and wear resistance, and can extend the service life of buildings.

2、 Application

1. Building exterior walls: Composite aluminum honeycomb panels can be used as building exterior wall materials, and their lightweight characteristics can reduce the weight of buildings, improve their thermal insulation performance and energy efficiency. Its high-strength characteristics can also ensure the safety and stability of buildings.

2. Roofing system: Composite aluminum honeycomb panels can be used as materials for roofing systems, and their lightweight characteristics can reduce the weight of the roof and improve its load-bearing capacity. Its corrosion resistance can also extend the service life of the roof.

3. Interior decoration: Composite aluminum honeycomb panels can be used as interior decoration materials, and their lightweight characteristics can increase the feeling and transparency of indoor spaces. Its high-strength characteristics can also ensure the safety and stability of indoor decorations.

3、 Summary

Composite aluminum honeycomb panel, as a new type of building material, has the characteristics of lightness, high strength, and corrosion resistance, and has been widely used in the construction industry. In the future, with the continuous improvement of people's requirements for building appearance and performance, composite aluminum honeycomb panels will be widely used and developed.

Customer service QQ

Customer service QQ