Industry information

Company News

- Aluminum honeycomb panel: a lightweight choice, a fresh architectural style

- Aluminum Ceiling: The New Favorite of Modern Home Furnishings, a Perfect Fusion of Fashion and Practicality

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

- Aluminum Curtain Wall: The Perfect Combination of Architectural Aesthetics and Pragmatism

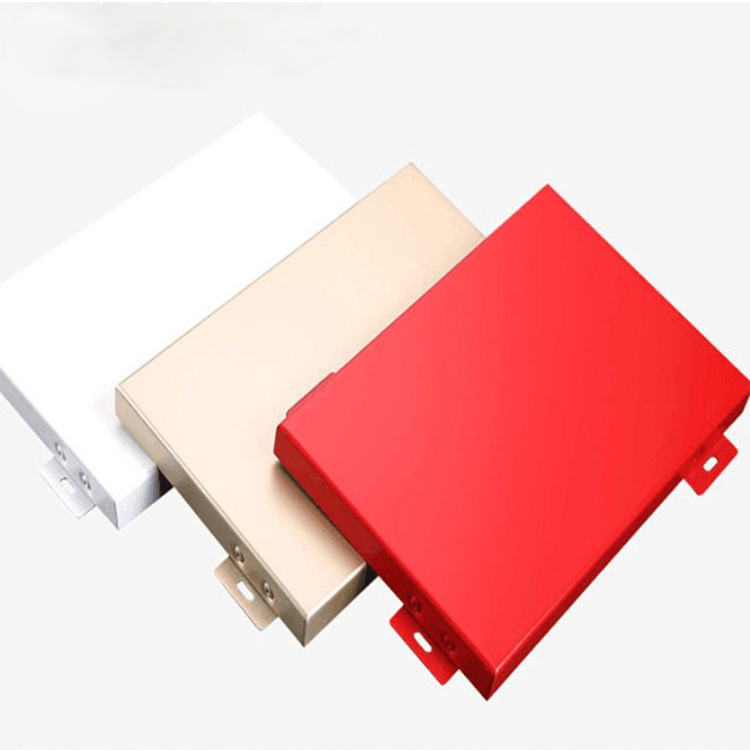

- Customize aluminum veneer to make buildings more durable and aesthetically pleasing

Industry dynamics

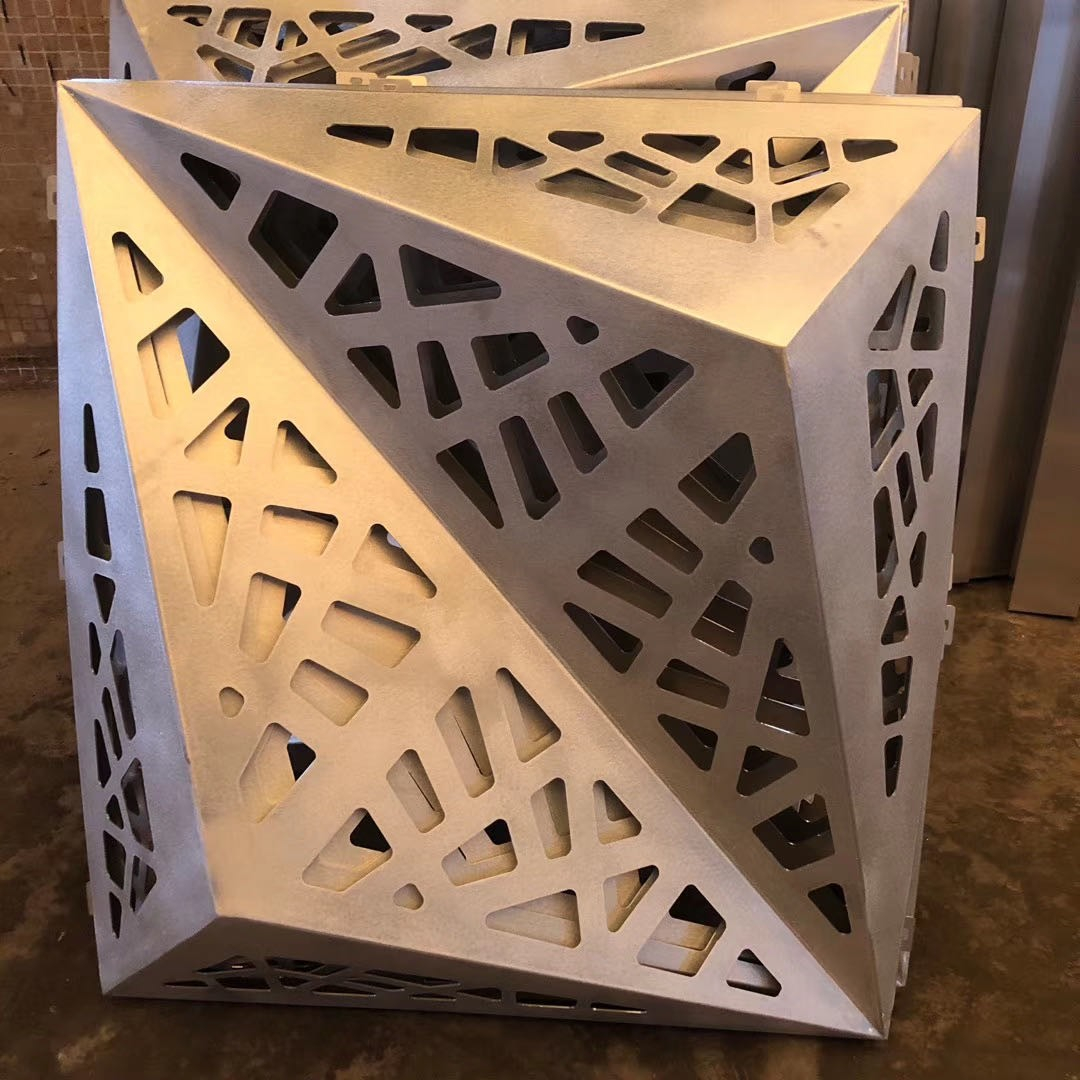

- 3mm aluminum veneer carving process display

- Dynamic analysis of aluminum veneer price market

- What is the weight of punched aluminum veneer?

- Honeycomb aluminum plate: a lightweight choice, revealing the new favorite of industrial materials

- Analysis of Marketing Channels for Aluminum Veneer Manufacturers

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- Has the production process of aluminum veneer reduced energy consumption?

- Can aluminum veneer be used in the design of building arch bridges?

- Can aluminum veneer achieve customized design?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Dust proof performance test of 1.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 15, 2025 17:50:28

- Click:0

1.5mmAluminum veneerIt is a common building material, and its dustproof performance has a significant impact on the service life and maintenance cost of buildings. This article will provide a detailed introduction to the dust-proof performance testing of 1.5mm aluminum veneer.

In terms of material properties, 1.5mm thick aluminum veneer usually has good corrosion resistance and weather resistance, and can adapt to certain changes in water, humidity, and temperature. Aluminum veneer also has good plasticity and processability, and can achieve various complex shapes and patterns.

To test the dust resistance of 1.5mm aluminum veneer, the following steps need to be taken:

1. Prepare experimental equipment, including dust generators, testing instruments, etc. A dust generator can generate dust particles of various sizes to simulate the dust situation in actual environments. The testing instrument can measure parameters such as particle content and mass concentration on the surface of aluminum veneer.

2. Conduct experiment: Place 1.5mm aluminum veneer in the laboratory and use a dust generator to generate a certain amount of dust particles to evenly cover the surface of the aluminum veneer. Then use testing instruments to inspect the surface of the aluminum veneer, recording parameters such as the quantity and mass concentration of dust particles.

3. Analysis results: Based on experimental data, parameters such as particle content and mass concentration on the surface of aluminum veneer can be calculated. If these parameters exceed the specified standard values, it indicates that the dustproof performance of the aluminum veneer is not good enough and corresponding measures need to be taken to improve it.

The dustproof performance test of 1.5mm thick aluminum veneer is a very important task that can help us understand its dustproof effect in practical applications. In practical applications, appropriate measures should be taken according to specific situations to improve its dust prevention performance and service life.

Customer service QQ

Customer service QQ