Corporate News

Company News

- Aluminum veneer: an elegant choice for modern architecture

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: making buildings more beautiful and high-end

- Aluminum veneer: the fashionable choice for modern architecture

Industry dynamics

- Unlimited creativity and diverse styles - infinite possibilities for ceiling painted aluminum veneer

- Aluminum veneer customization, creating an artistic journey of personalized space

- What is the manufacturing process of hyperbolic aluminum veneer?

- Honeycomb aluminum plate: What secrets are hidden behind its lightweight design?

- Aluminum veneer: the "green new clothes" of modern architecture

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- How can aluminum veneer improve the appearance of buildings?

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Can aluminum veneer be used in the design of building arch bridges?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The 'invisible' charm of honeycomb aluminum plate: a lightweight yet sturdy secret weapon!

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 12, 2025 12:40:04

- Click:0

Today, let's talk about a somewhat mysterious yet super practical material - honeycomb aluminum plate. This thing may sound a bit unfamiliar to many people, but it has many applications in our daily lives.

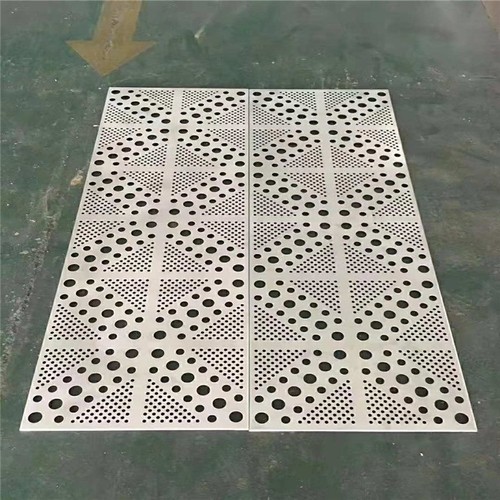

We need to understand that the magic of honeycomb aluminum panels lies in their "honeycomb" structure. Imagine a beehive built by bees, isn't it both lightweight and sturdy? Honeycomb aluminum plate is inspired by this principle. It is composed of a honeycomb like structure and thin aluminum plates, so it is lightweight and has high strength.

I remember one time, I participated in a construction site visit and saw workers building a display stand with honeycomb aluminum panels. I was surprised by its lightness, it was as thin as a piece of cardboard, but when the workers put it on, it was as stable as a rock. I took a closer look and found that the honeycomb structure played a significant role behind it.

The application of honeycomb aluminum plate can be widely used. In the aerospace field, this material can help aircraft reduce weight and improve fuel efficiency. You may not even notice this little secret while flying. In automobile manufacturing, honeycomb aluminum panels are also a treasure, as they can reduce the weight of vehicles and enhance the driving experience.

Speaking of which, I have a friend who drives a hybrid car that uses honeycomb aluminum panels. He said that this type of car has much lower fuel consumption than similar models, and the body's seismic performance is also stronger.

Don't underestimate this small aluminum plate, it can also be used in the construction industry. Some high-end commercial buildings in our city may have roofs made of honeycomb aluminum panels. This material is not only energy-saving and environmentally friendly, but also has a certain sound insulation effect, making it a model of green building.

Looking at electronic devices again, there are also many applications of honeycomb aluminum panels. Honeycomb aluminum panels are sometimes used for the cooling system of mobile phones and computers. It has good heat dissipation effect and is not prone to rusting like traditional metals.

Honeycomb aluminum panels are not without their drawbacks. Its price is relatively high and not something that ordinary consumers can easily buy and use. But its flaws do not overshadow its strengths, and its advantages clearly outweigh its weaknesses.

Let's talk about the production process of honeycomb aluminum sheet again. During this process, craftsmen need to go through multiple procedures to ensure the quality of each honeycomb aluminum plate. Cut the aluminum plate into rectangular shapes of a certain size, and then press them into honeycomb shapes using a press. This process requires very precise process control to ensure that the shape and size of the honeycomb are uniform and consistent.

Although honeycomb aluminum panels may seem simple, the technological content behind them is actually not low. It is not just a building material or industrial product, but also a perfect combination of technology and aesthetics.

What I want to say is that there are honeycomb aluminum panels everywhere in life, but we don't pay much attention to them in our daily lives. Next time you walk on the streets of the city, you may want to pay more attention, maybe you will find its figure in some inconspicuous place.

Honeycomb aluminum plate, this name sounds a bit cold and icy, but it contains infinite possibilities. It is like an 'invisible' magician, using the dual charm of lightness and solidity to change our lives.

Customer service QQ

Customer service QQ