Industry information

Company News

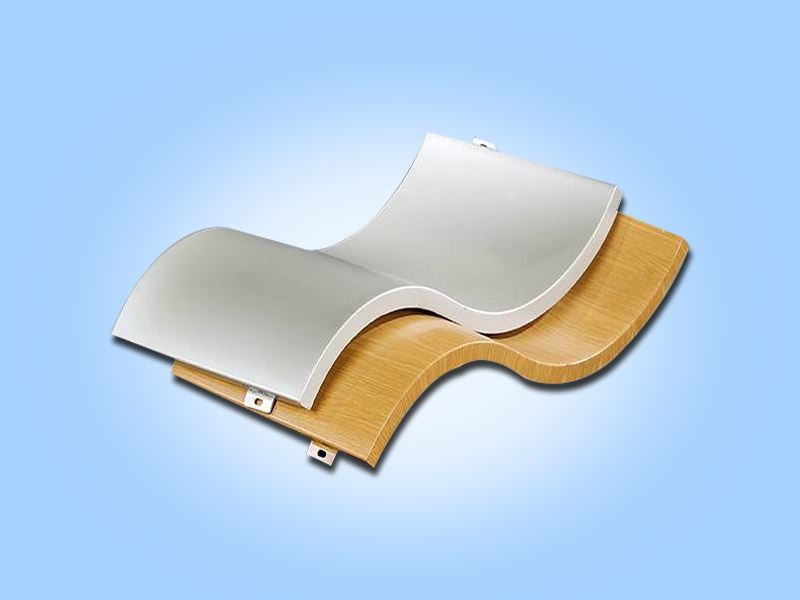

- Aluminum veneer customization, creating a new choice for personalized space!

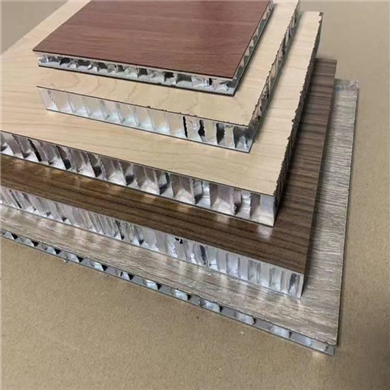

- The secret of aluminum honeycomb panel: the perfect combination of lightness and sturdiness

- The magical charm of aluminum honeycomb panels: a lightweight and sturdy secret weapon!

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

- Honeycomb aluminum plate: the technological secret behind its lightweight design

Industry dynamics

- Aluminum veneer: the most popular exterior wall decoration material in modern architecture

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- Aluminum veneer: the "silver fashionable clothing" of modern architecture

- Innovative design of hollow aluminum veneer ceiling for spatial aesthetics

- What are the maintenance methods for punched aluminum veneer?

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Has the production process of aluminum veneer reduced energy consumption?

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer be used in the design of building arch bridges?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to ensure the surface smoothness of punched aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 27, 2025 19:07:14

- Click:0

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its surface smoothness is also a very important factor. The following will introduce how to ensure the surface smoothness of punched aluminum veneer from the following aspects.

1. Raw material selection

The surface smoothness of punched aluminum veneer is related to its raw material selection. Generally speaking, high-quality punched aluminum veneer should use raw materials that meet environmental standards and minimize their impact on the environment. The quality of raw materials also affects the surface smoothness of punched aluminum veneer. When choosing perforated aluminum veneer, comprehensive consideration and selection should be made based on the actual situation.

1. Production process

The surface smoothness of punched aluminum veneer is also related to its production process. The production process includes multiple stages such as raw material preparation, mold making, stamping, drilling, and surface treatment. In the production process, it is necessary to pay attention to the optimization and control of the process flow to reduce the generation of waste and pollutants. It is also necessary to pay attention to the cleanliness and maintenance of the equipment to ensure the hygiene and safety of the production process.

1. Product usage

During the use of punched aluminum veneer, attention should also be paid to surface smoothness issues. For example, it is necessary to avoid behaviors such as littering and environmental pollution during use; After use, it is necessary to clean and dispose of waste in a timely manner to reduce the impact on the environment; During use, it is also necessary to comply with relevant fire prevention regulations and rules, such as prohibiting the use of non compliant coatings, sealants, etc.

1. Surface treatment

The surface smoothness of punched aluminum veneer is also related to its surface treatment. Generally speaking, perforated aluminum veneer treated with anodizing is smoother and more delicate than untreated perforated aluminum veneer. This is because anodizing treatment can increase the hardness and strength of aluminum materials, while also increasing their density and weight. In some occasions where high surface smoothness is required, such as indoor decoration, punched aluminum veneer materials that have undergone anodizing treatment are usually chosen.

Ensuring the surface smoothness of punched aluminum veneer is a comprehensive issue that requires consideration and improvement from multiple aspects such as raw material selection, production process, product use, and surface treatment. Only by continuously optimizing and improving production processes and technological means can we produce smoother, more delicate, durable, energy-saving, and efficient punched aluminum veneer products, making greater contributions to society and the environment.

Customer service QQ

Customer service QQ