Corporate News

Company News

- Aluminum veneer: understated luxury in modern architecture

- Aluminum ceiling: the 'invisible hero' of modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum honeycomb panel: the "hidden master" of the construction industry

- Aluminum ceiling, creating a new trend of modern space

Industry dynamics

- Aluminum ceiling trend: the beauty of lightness, the new favorite of home furnishings

- The secret of aluminum honeycomb panel: the new favorite of lightweight and high-strength construction

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum Curtain Wall: Aesthetic Transformation of Modern Architecture

- Aluminum Ceiling: Creating a New Trend in Modern Space

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How does the plasticity of aluminum veneer affect building comfort?

- Has the production process of aluminum veneer reduced energy consumption?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- What is the manufacturing process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

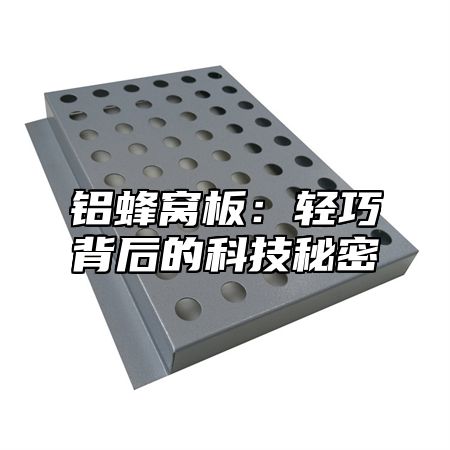

Aluminum honeycomb panel: the technological secret behind its lightweight design

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-03 18:38:31

- Click:0

Ladies and gentlemen, today let's talk about a magical material - aluminum honeycomb panel. Does this name sound a bit fancy? It is right beside us, silently adding color to our lives.

Let's talk about the characteristics of aluminum honeycomb panels. It is lightweight, sturdy, soundproof, and heat-insulating, making it an all-around player. Don't believe me? Let's explore it further!

Imagine a honeycomb, each small honeycomb resembling a small room with an empty center. This structure makes the honeycomb both lightweight and sturdy. Aluminum honeycomb panel is based on the structure of honeycomb, using aluminum plate as the shell and filling the middle with honeycomb shaped aluminum honeycomb. This design makes the aluminum honeycomb panel both lightweight and sturdy, just like a honeycomb.

Lightweight, let's talk about it first. The density of aluminum honeycomb panels is very low, only about one-third of that of steel. The products made with it are lightweight and easy to transport. Aluminum honeycomb panel walls made of aluminum honeycomb panels weigh only 1/4 of traditional walls, greatly reducing the burden on buildings.

Speaking of sturdiness. Aluminum honeycomb panels have high bending, bending, and impact resistance. This is because the honeycomb structure of aluminum honeycomb panels gives them excellent resistance to deformation. Products made of aluminum honeycomb panels have a long service life and are not easily damaged.

Let's talk about sound insulation and thermal insulation. Aluminum honeycomb panels have excellent sound and heat insulation properties. This is because the structure of the aluminum honeycomb panel allows air to form multiple enclosed small spaces inside the panel, thereby reducing the transfer of sound waves and heat. Doors, windows, walls, etc. made of aluminum honeycomb panels have excellent sound insulation and thermal insulation effects.

What are the application scenarios of aluminum honeycomb panels?

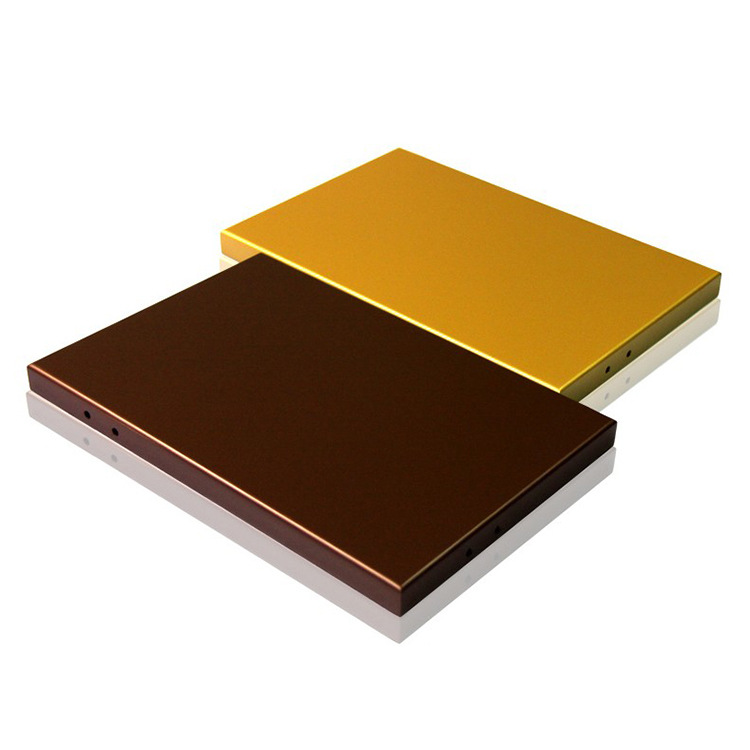

In the field of architecture. Aluminum honeycomb panels can be used as exterior walls, interior walls, ceilings, etc. of buildings. It is not only beautiful and elegant, but also has excellent sound insulation and thermal insulation performance, making it the preferred material for modern architecture.

In the field of transportation. Aluminum honeycomb panels can be used as interior and exterior decorations for vehicles such as cars, trains, and ships. It is lightweight, sturdy, and can also improve the safety performance of vehicles.

Aerospace field. Aluminum honeycomb panels can be used as structural materials for aircraft, rockets, and other aerospace vehicles. It is lightweight, sturdy, and can also improve the performance of aerospace vehicles.

In the field of home furnishings. Aluminum honeycomb panels can be used as household items such as furniture and cabinets. It is aesthetically pleasing and has excellent sound and heat insulation properties, making it the preferred material for modern homes.

How is aluminum honeycomb panel made?

Cut the aluminum plate into the required size. Place the aluminum plate into the honeycomb mold and form a honeycomb structure through high-temperature heating and pressure. Weld or bond honeycomb aluminum plates with aluminum plates to produce aluminum honeycomb panels.

During this process, it is important to pay attention to the following points:

1. The thickness of the aluminum plate should be moderate, as being too thick or too thin can affect the performance of the aluminum honeycomb panel.

2. The design of honeycomb molds should be reasonable to ensure the uniformity and stability of the honeycomb structure.

3. The welding or bonding process should be rigorous to ensure the strength and sealing of the aluminum honeycomb panel.

4. Pay attention to environmental protection and use non-toxic and harmless welding and bonding materials.

Aluminum honeycomb panel is a magical material that is lightweight, sturdy, soundproof, and heat-insulating, widely used in various fields. With the continuous development of technology, the application prospects of aluminum honeycomb panels will be even broader. Hey guys, what is your opinion on aluminum honeycomb panels? Welcome to leave a message in the comment section for communication!

Customer service QQ

Customer service QQ