Corporate News

Company News

- Aluminum ceiling: poetic embellishment of modern space

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum ceiling: the 'invisible guardian' of modern architecture

- Aluminum veneer: an elegant choice for modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Carved aluminum veneer adds a sense of three dimensionality and texture to the space

- The Beauty of Aluminum Curtain: The Fashionable Coat of Urban Architecture

- The secret of aluminum honeycomb panel: lightweight and high-strength, the new favorite of future architecture

- Aluminum curtain wall: the fashionable coat of urban architecture

- Innovative technology package column twisted aluminum veneer design

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How does the plasticity of aluminum veneer affect building comfort?

- Is the surface treatment of aluminum veneer durable?

- Has the production process of aluminum veneer reduced energy consumption?

- What is the manufacturing process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

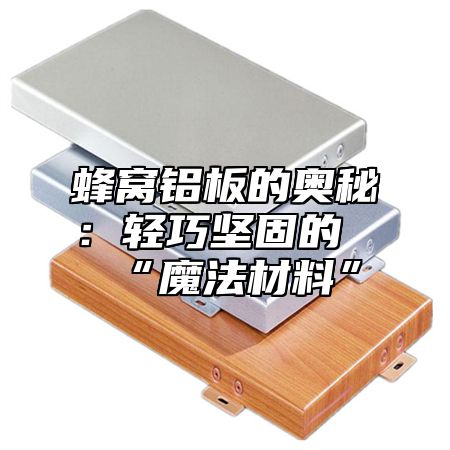

The mystery of honeycomb aluminum plate: a lightweight and sturdy 'magic material'

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-03 04:38:49

- Click:0

Friends, today let's talk about a magical material - honeycomb aluminum plate. You may not be familiar with this name, but it is highly effective in many fields! Let me sell you a trick first. Let me describe a scene for you: Imagine a lightweight board that can almost ignore weight, but can withstand unimaginable weight. Isn't it amazing?

The name honeycomb aluminum plate is quite interesting, as it combines the characteristics of honeycomb and aluminum plate. Honeycomb, a widely existing structure in nature, is lightweight and has high strength, which is the main source of inspiration for the design of honeycomb aluminum plates. Aluminum, as a lightweight metal, has a wide range of applications, from aircraft manufacturing to building roofs.

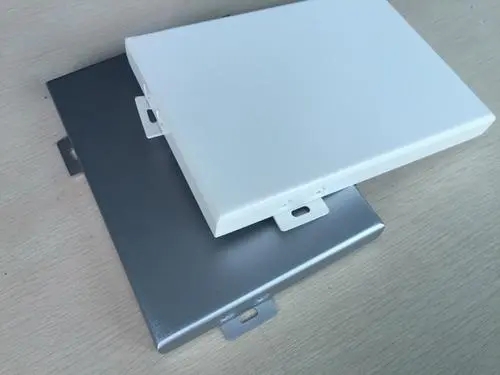

Let's talk about its' lightness' first. Do you know how large a basketball court is? Assuming it is 2000 square meters, if we use ordinary aluminum panels to make the ceiling, we would need at least 30 tons of aluminum. And honeycomb aluminum sheet may only require about 5 tons. What is this concept? Equivalent to losing the weight of a large truck! The first major advantage of honeycomb aluminum plate is its "lightness".

Let's talk about its' durability 'again. Someone may ask, can such a lightweight material withstand the weight of a building? The structure of honeycomb aluminum plate determines its strength. Its interior is a hexagonal honeycomb structure, which not only reduces weight but also effectively disperses stress. Honeycomb aluminum plate is not only lightweight, but also sturdy.

What are its application scenarios?

In the aviation field. The weight of an airplane directly affects its flight performance, and honeycomb aluminum panels solve this problem perfectly. Aircraft components made of honeycomb aluminum panels can reduce weight while ensuring performance, thereby improving fuel efficiency.

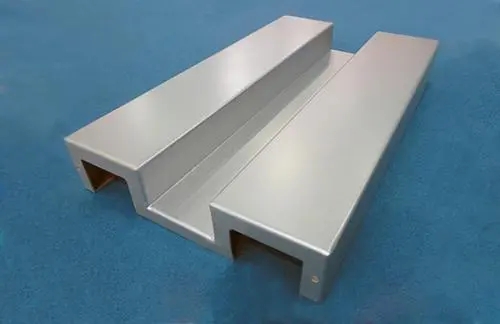

Construction industry. Honeycomb aluminum panels are widely used in the interior and exterior decoration of buildings, such as ceilings, walls, etc. It can not only beautify the environment, but also play a good role in sound and heat insulation.

For example, automobile manufacturing. Nowadays, many cars are pursuing lightweight, and honeycomb aluminum panels come in handy. Automotive components made of honeycomb aluminum panels can reduce fuel consumption and improve power performance of vehicles.

The application of honeycomb aluminum sheet is far more than that. It also has a wide range of applications in fields such as solar panels and medical devices.

How is honeycomb aluminum plate made?

The production process of honeycomb aluminum plate is actually not complicated. Cut, punch and process the aluminum plate, and then weld it into a honeycomb structure. Surface treatment of honeycomb aluminum plates, such as spraying, baking paint, etc., to improve their durability and aesthetics.

Honeycomb aluminum plates also have their drawbacks. For example, the price is relatively high and the difficulty of recycling is high. The advantages of honeycomb aluminum sheet far outweigh its disadvantages, making it an indispensable material in modern society.

What I want to say is that the emergence of honeycomb aluminum panels is a perfect combination of human intelligence and nature. It not only showcases human creativity, but also allows us to gain a deeper understanding of the natural world. Perhaps in the future, we will discover more magical "magic materials" that will bring more surprises to our lives.

Honeycomb aluminum plate is a lightweight and sturdy "magic material" widely used in aviation, construction, automotive and other fields. It is not only the crystallization of human wisdom, but also a precious treasure bestowed upon us by nature. Let's look forward to more magical "magic materials" appearing in the future, bringing more beauty to our lives.

Customer service QQ

Customer service QQ