Corporate News

Company News

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum Curtain Wall: The Magician of Light and Shadow in Architectural Aesthetics

- The Charm of Honeycomb Aluminum Plate: A Lightweight and High Strength Modern Material

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer: the fashionable outerwear of modern architecture

Industry dynamics

- Aluminum honeycomb panel: a perfect combination of lightweight and sturdy

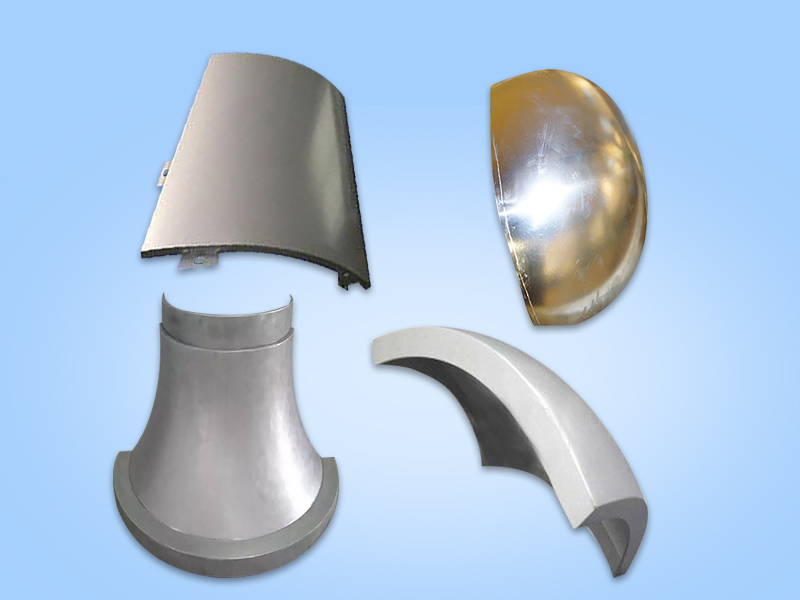

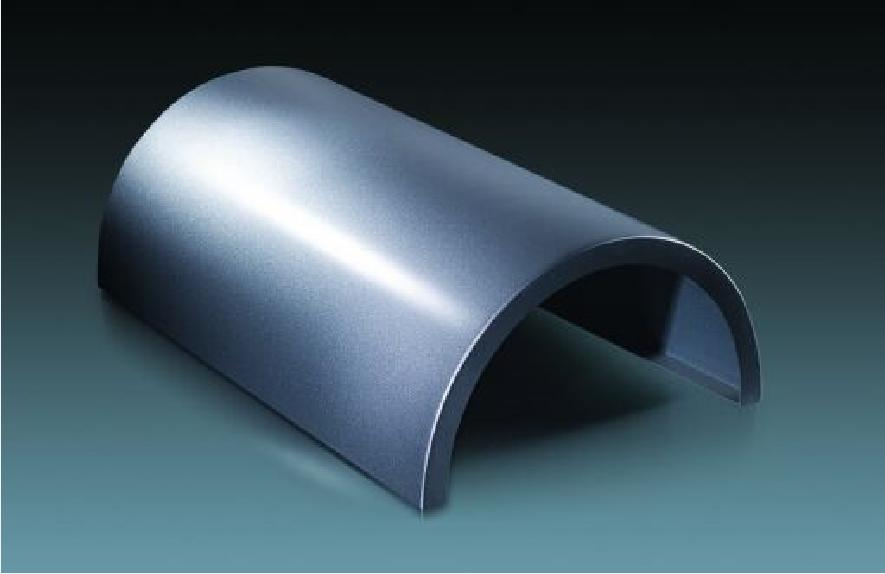

- Characteristics of curved aluminum veneer

- The fashionable choice of aluminum veneer in modern architecture

- OMG! These aluminum veneer creative designs are simply breathtaking!

- Customized aluminum veneer, personalized space new trend

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Has the production process of aluminum veneer reduced energy consumption?

- Is the surface treatment of aluminum veneer durable?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-03 20:45:06

- Click:0

Dear readers, today let's talk about a magical material - aluminum honeycomb panel. This thing may sound a bit unfamiliar to everyone, but it shines brightly in fields such as architecture, aerospace, and automotive manufacturing. Let's first talk about its charm.

Let's talk about the name of aluminum honeycomb panel. It is composed of aluminum honeycomb paper and aluminum plate composite, and the honeycomb structure design has found a balance between lightness and sturdiness. It's like a magician who blends the seemingly contradictory characteristics of lightness and sturdiness perfectly.

Let's first talk about its lightness. Aluminum honeycomb panels have low density, light weight, and are super convenient for transportation and installation. Imagine holding an aluminum honeycomb panel as light as a feather. This is not like those heavy boards that make people feel back pain when carrying them. In the field of architecture, lightweight aluminum honeycomb panels greatly reduce the weight of buildings, making high-rise buildings as light as feathers.

Let's talk about its durability again. Despite being lightweight, aluminum honeycomb panels have excellent compressive and bending resistance. The honeycomb structure is like small springs that evenly distribute pressure across the entire board, allowing it to remain stable when subjected to external forces. This is like a judo master, seemingly weak but actually possessing immense strength.

What are the uses of aluminum honeycomb panels? Let's count it.

In the field of construction, aluminum honeycomb panels have shown great potential. It can be used for curtain walls, roof panels, ceilings, etc., adding a unique charm to buildings. Imagine a high-rise building with aluminum honeycomb panels decorating its exterior walls, which are both beautiful and practical.

Aluminum honeycomb panels also play an important role in the aerospace industry. Its lightweight and sturdy characteristics enable aircraft, spacecraft, and other aerospace vehicles to reduce their own weight while ensuring sufficient strength. It's like a graceful dancer dancing gracefully in the air.

In the field of automobile manufacturing, the application of aluminum honeycomb panels is becoming increasingly widespread. It can be used for car body, interior and other parts to improve the overall performance of the car. It's like a racer driving a lightweight yet sturdy race car, speeding on the track.

The application of aluminum honeycomb panels goes far beyond this. It also plays an important role in fields such as shipbuilding and packaging.

How is aluminum honeycomb panel made? Its production process is not complicated. Composite aluminum honeycomb paper and aluminum plate to form a honeycomb structure. By pressing, cutting, and other processes, the desired size and shape are produced. After surface treatment, the aluminum honeycomb panel is completed.

In the production process of aluminum honeycomb panels, we should also pay attention to environmental protection. Using environmentally friendly materials to reduce pollution emissions, making aluminum honeycomb panels a representative of green building materials.

Having said so much, you may think that aluminum honeycomb panel is a perfect material. But in fact, it also has its own shortcomings. Its price is relatively high and not everyone can afford it. Its surface treatment process is relatively complex and requires certain technical support.

However, the flaws do not overshadow the strengths, and the advantages of aluminum honeycomb panels are still evident. In the future development, we believe that aluminum honeycomb panels will receive more attention and application, bringing more convenience to our lives.

Aluminum honeycomb panel, this magical material, shines in various fields with its perfect combination of lightness and strength. Let's look forward together, aluminum honeycomb panels will bring us more surprises in the future!

Customer service QQ

Customer service QQ