Industry information

Company News

- Aluminum veneer: understated luxury in modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer: the fashionable "coat" of modern architecture

- The charm of aluminum veneer: a perfect fusion of lightness and durability

- Aluminum ceiling new fashion, new darling of home decoration

Industry dynamics

- Aluminum curtain wall: a model of the integration of architectural aesthetics and technology

- Aluminum veneer customization, creating a new trend of personalized space

- Beautiful and elegant waterproof and anti-corrosion wall fluorocarbon aluminum veneer has been unanimously recognized by designers

- Unique style! Hollow carved aluminum veneer adds personality to the building

- The secret of aluminum veneer: the story behind its lightness

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- How can aluminum veneer improve the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer be used in the design of building arch bridges?

- Has the production process of aluminum veneer reduced energy consumption?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

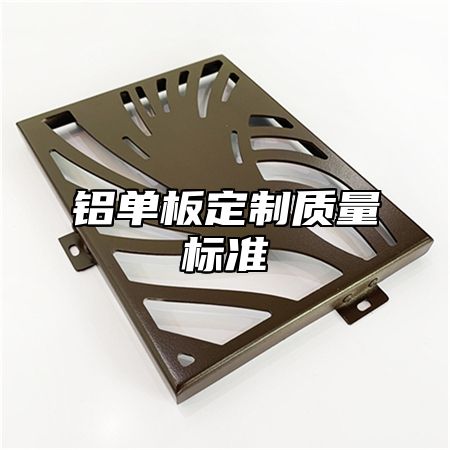

Quality standard for customized aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-01 21:52:58

- Click:0

Aluminum veneerCustomization is a personalized customization service based on customer needs and requirements. The control and assurance of quality standards are key links in ensuring product quality and customer satisfaction when customizing aluminum veneer. Below, we will provide a detailed introduction to the quality standards for customized aluminum veneer.

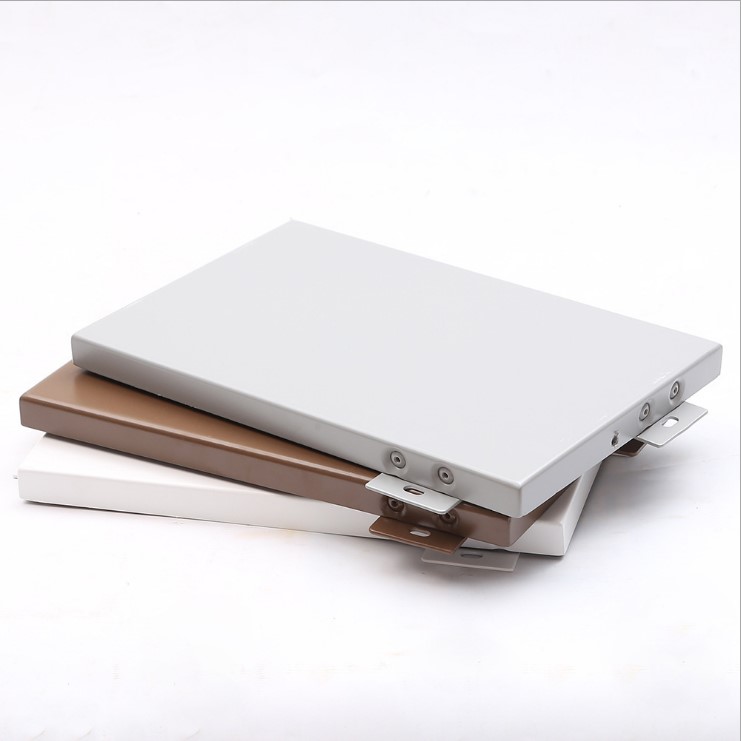

1、 Material Quality Standards

The materials used for customized aluminum veneer should be high-quality aluminum alloy materials that comply with national standards and industry regulations. When purchasing materials, it is necessary to conduct strict testing and inspection on each batch of materials to ensure that the quality and performance of the materials meet the requirements. At the same time, it is necessary to compare and analyze different types of aluminum veneers to select the most suitable product material.

2、 Processing quality standards

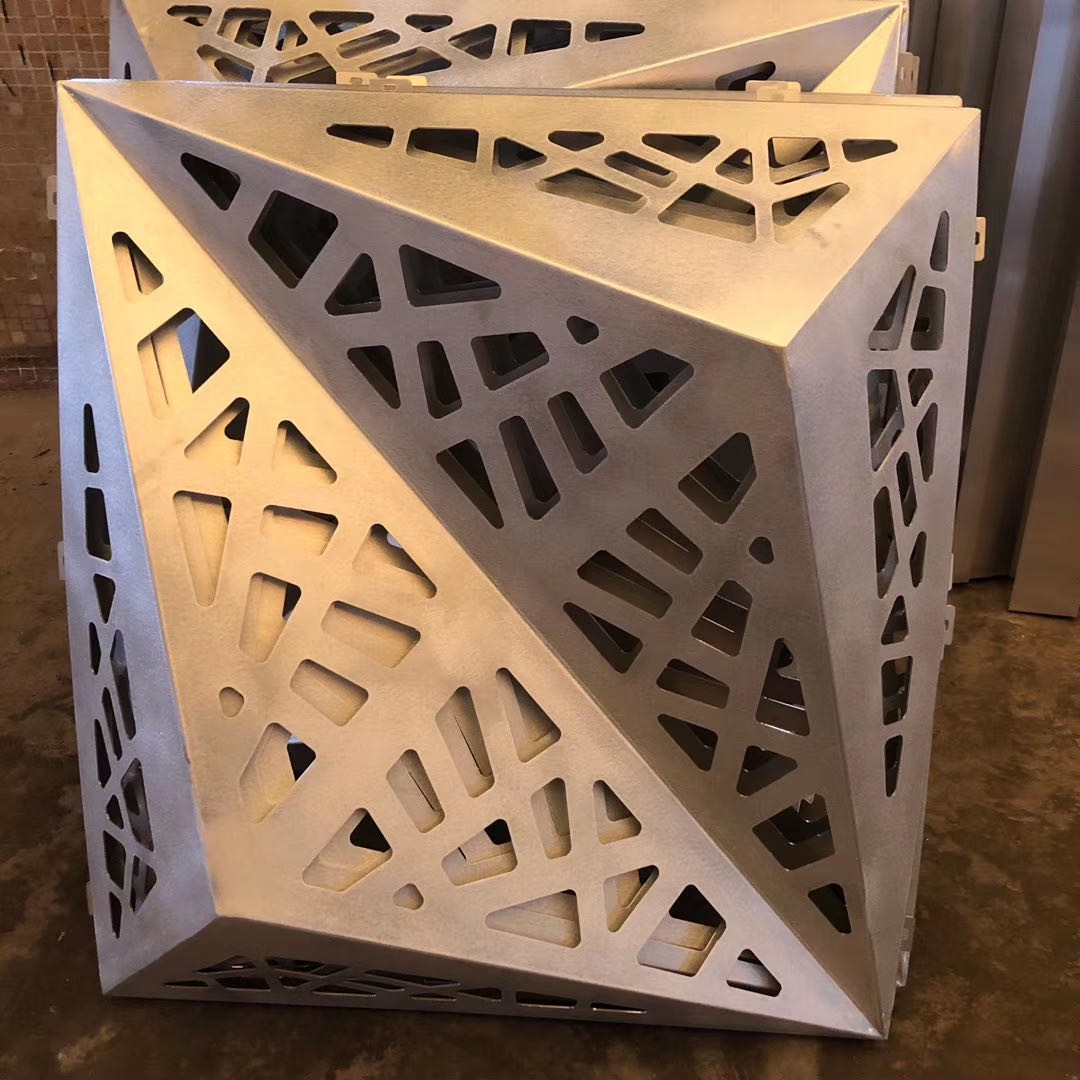

The customized processing process of aluminum veneer requires the use of advanced processing equipment and technology to ensure the accuracy and efficiency of the product. During the processing, attention should be paid to quality control and inspection at various stages, such as cutting, bending, punching, etc., to ensure the dimensional accuracy and surface smoothness of the product. At the same time, regular maintenance and upkeep of processing equipment are required to ensure its normal operation and production efficiency.

3、 Surface treatment quality standards

The surface treatment of customized aluminum veneer requires multiple processes, such as anodizing, electrophoretic coating, etc. In the surface treatment process, it is necessary to strictly control the quality of each link, such as coating thickness, adhesion, color uniformity, etc., to ensure the appearance and durability of the product. At the same time, it is necessary to conduct quality inspection and testing on the surface treated aluminum veneer to ensure that the product meets quality standards and customer requirements.

4、 Packaging and transportation quality standards

The packaging and transportation of customized aluminum veneer need to comply with national standards and industry regulations to ensure that the product is not damaged or deformed during transportation. Suitable packaging materials and methods need to be selected during the packaging process, and strict packaging labeling and marking should be carried out to prevent accidental disassembly and misuse. At the same time, it is necessary to conduct quality inspection and testing on the packaged aluminum veneer to ensure that the product meets quality standards and customer requirements.

5、 Conclusion and Prospect

Through the introduction of the above quality standards for customized aluminum veneer, it can be seen that quality control and assurance are required in multiple stages of aluminum veneer customization, including material procurement, processing and manufacturing, surface treatment, packaging and transportation, in order to ensure product quality and customer satisfaction. In the future, with the continuous advancement of technology and changes in market demand, the aluminum veneer industry will pay more attention to the improvement of product quality and service level to meet the needs and expectations of consumers. At the same time, it is necessary to strengthen communication and cooperation with other fields to provide consumers with more comprehensive and objective selection criteria and service support. For enterprises, they should strengthen research and development innovation and technological upgrading, improve product quality and service level, in order to enhance their competitiveness and profitability. At the same time, it is necessary to strengthen cooperation and communication with other brands to jointly promote the development of the entire aluminum veneer industry.

Customer service QQ

Customer service QQ