Industry information

Company News

- Aluminum curtain wall: a shining pearl in modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum ceiling, creating a Xintiandi for home furnishing

- Aluminum Curtain Wall: The Bright Coat of Modern Architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

Industry dynamics

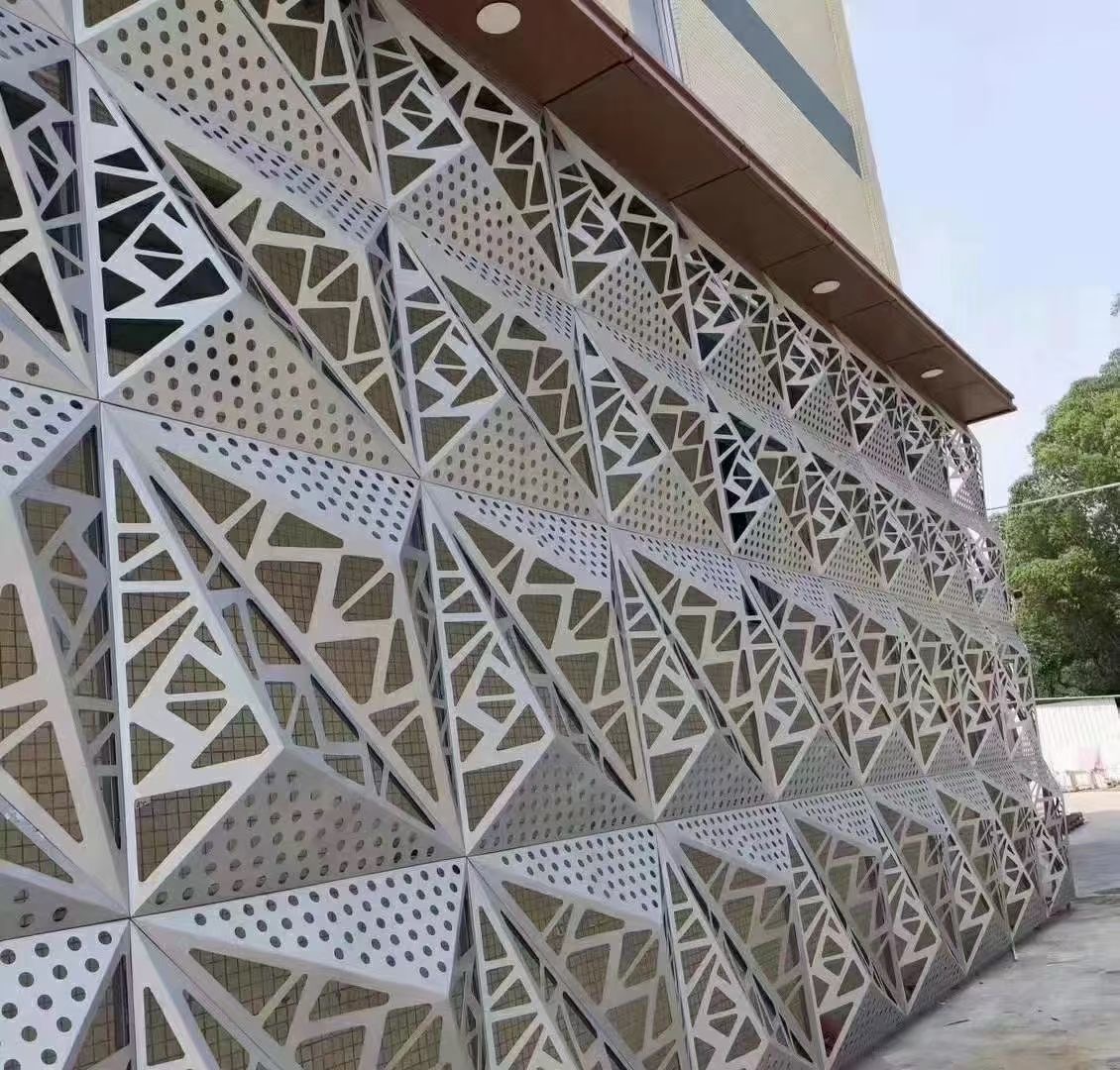

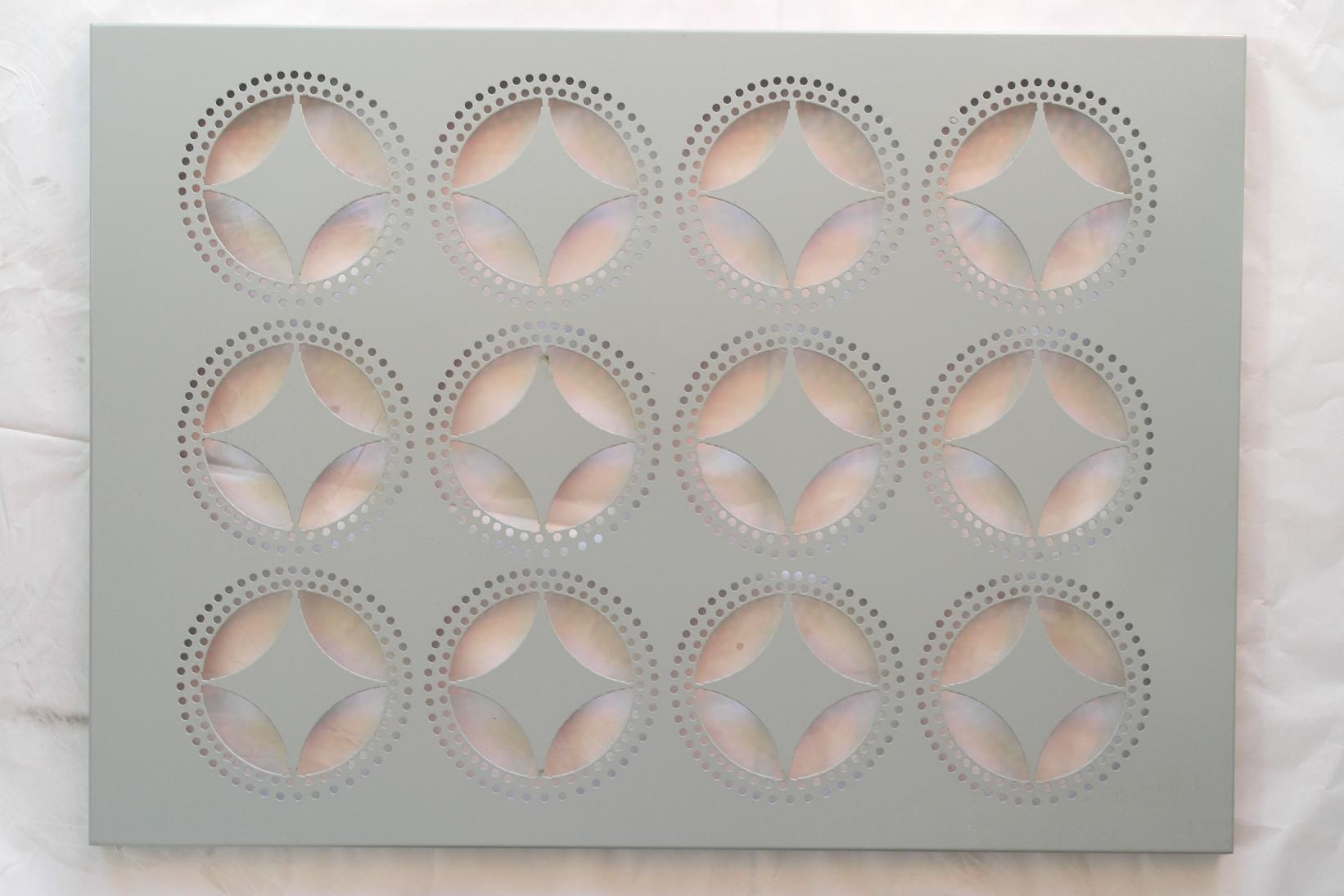

- Punched aluminum veneer adds a unique style to buildings

- Analysis of the appearance effect of 3mm aluminum veneer under punching process

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer customization, creating personalized space art

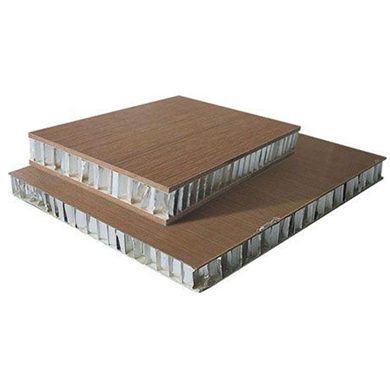

- Unveiling the magical charm of aluminum honeycomb panels, the new darling of home decoration!

Frequently asked questions

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- Can aluminum veneer achieve customized design?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Has the production process of aluminum veneer reduced energy consumption?

- Can aluminum veneer be used in the design of building arch bridges?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

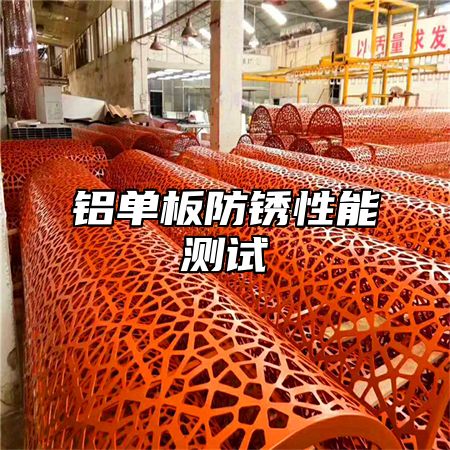

Anti rust performance test of aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 28, 2025 11:46:54

- Click:0

Aluminum veneerAs a commonly used building material, its rust prevention performance is also one of its important performance indicators. This article will provide a detailed introduction to the anti rust performance testing of aluminum veneer from the aspects of material characteristics, surface treatment, and application environment.

1、 Material characteristics of aluminum veneer

The main component of aluminum veneer is aluminum, which has good corrosion resistance. Aluminum veneer also has the advantages of lightweight and low thermal conductivity, which can effectively improve the overall rust prevention performance of buildings. However, aluminum veneers are sensitive to oxidation reactions and are prone to rusting.

2、 The influence of surface treatment on anti rust performance

The surface treatment of aluminum veneer also has a significant impact on its rust prevention performance. Common surface treatment methods include anodizing, electrophoretic coating, fluorocarbon spraying, etc. Fluorocarbon spraying is a commonly used surface treatment method that can improve the rust resistance of aluminum veneer by forming a layer of fluorocarbon coating on the aluminum surface. This layer of fluorocarbon coating can effectively isolate air and moisture, prevent oxidation reactions of aluminum veneer, and achieve the purpose of rust prevention. Fluorocarbon coatings also have good weather resistance and anti-corrosion properties, which can effectively extend the service life of aluminum veneers.

3、 The impact of application environment on anti rust performance

The application environment of aluminum veneer can also affect its rust prevention performance. Generally speaking, aluminum veneer is easily affected in humid, acidic, and alkaline environments, leading to a decrease in its rust prevention performance. When using aluminum veneer, it is necessary to choose the appropriate surface treatment method according to the specific application environment, and pay attention to maintenance to extend its service life and maintain good rust prevention effect.

4、 Conclusion

The rust prevention performance of aluminum veneer is closely related to its material characteristics, surface treatment, and application environment. In order to ensure that aluminum veneer has good anti rust performance, it is necessary to strictly control the quality of each link in the production process and select appropriate surface treatment methods according to the specific application environment. Regular maintenance is also required during use to extend its service life and maintain good rust prevention effect.

Customer service QQ

Customer service QQ