Industry information

Company News

- Aluminum veneer: a low-key luxury choice in modern architecture

- Aluminum Curtain Wall: The Silver Coat of Modern Architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: easily upgrade the appearance of buildings

- Aluminum veneer, the "fashionable coat" of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

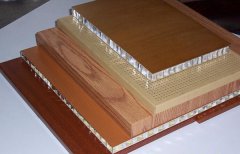

- The secret of honeycomb aluminum plate: the technological power behind its lightness

- Aluminum veneer customization, creating a new trend of personalized space!

- Honeycomb aluminum plate: the secret power behind lightness

- Honeycomb aluminum plate: a secret weapon as light as a feather and as solid as a rock!

Frequently asked questions

- How does the plasticity of aluminum veneer affect building comfort?

- Can aluminum veneer achieve customized design?

- What is the manufacturing process of aluminum veneer?

- Can aluminum veneer be used in the design of building arch bridges?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of Manufacturing Process for Carving Ceiling Aluminum Veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 2, 2025 10:33:18

- Click:0

Carving ceilingAluminum veneerIt is a new type of building decoration material with high decorative and artistic value. Its manufacturing process is one of the important factors affecting its quality and aesthetics. Below, we will introduce in detail the manufacturing process of carved ceiling aluminum veneer.

1、 Raw material preparation

The main raw material for carving ceiling aluminum veneer is aluminum alloy sheet, which needs to be selected according to the customer's needs. We also need to prepare some auxiliary materials, such as corner codes, keels, etc.

2、 Cutting and processing

Cut and process the aluminum alloy sheet according to the requirements of the design drawings to obtain the desired size and shape. Cutting and processing can be carried out using CNC machine tools or manual operations.

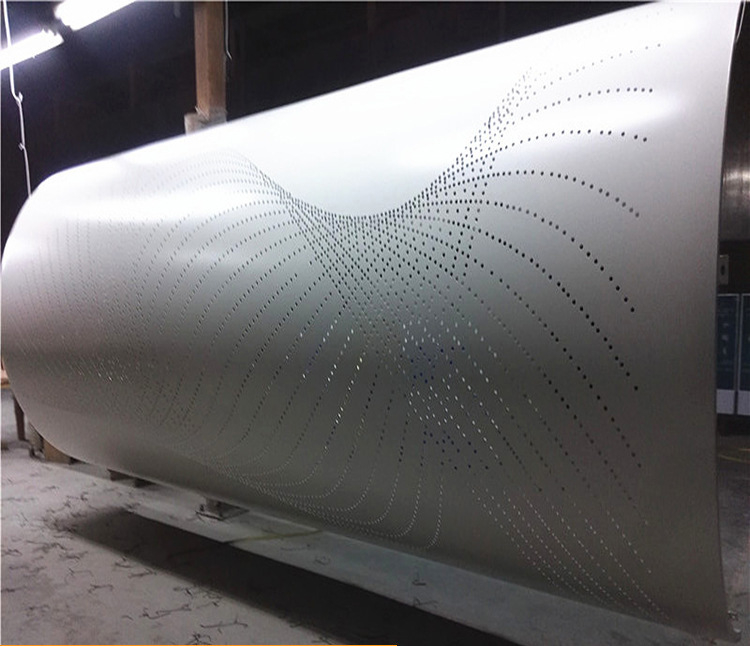

3、 Drilling processing

Drill holes on aluminum alloy sheets for subsequent carving processing. Drilling processing can be carried out using equipment such as drilling machines or punching machines.

4、 Carving processing

Place the perforated aluminum alloy sheet on the engraving machine for engraving processing. The engraving machine can perform precise engraving according to the requirements of the design drawings, thereby obtaining the desired patterns and textures.

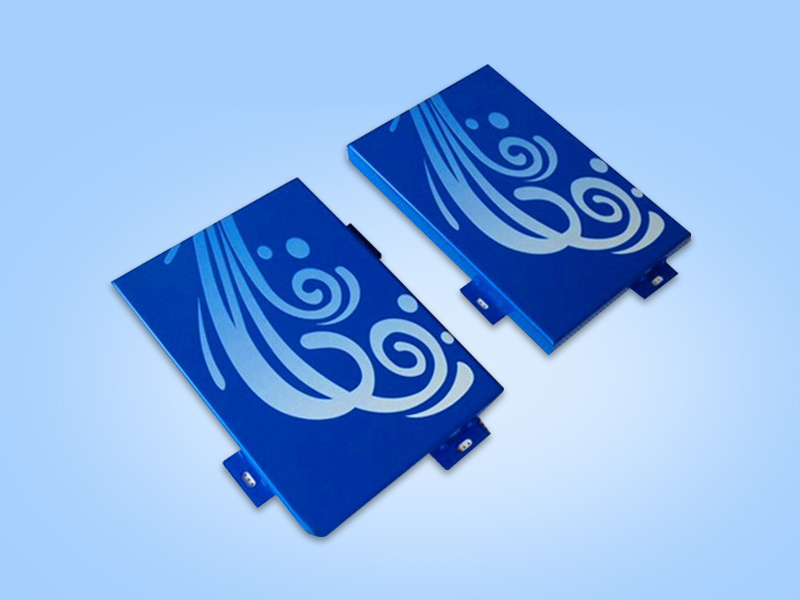

5、 Surface treatment

Surface treatment is applied to aluminum alloy sheets that have been carved and processed to improve their aesthetics and corrosion resistance. Surface treatment can be carried out by anodizing, spraying, and other methods.

6、 Installation and construction

Install the surface treated aluminum alloy sheet onto the ceiling, and use auxiliary materials such as keels to support it firmly and reliably. During the installation process, it is necessary to pay attention to the direction and angle of the aluminum veneer to ensure that it is coordinated with the overall style of the building.

As a new type of building decoration material, carved ceiling aluminum veneer has high decorative and artistic value. Through careful design and production, it can present unique textures and colors, adding a unique charm to the building. In the future, with the continuous advancement of technology and the continuous development of society, carved ceiling aluminum veneer will play a more important role.

Customer service QQ

Customer service QQ