Industry information

Company News

- The magical charm of aluminum honeycomb panels reveals the new trend of lightweight building materials!

- Property: Aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum ceiling, not just another option for ceilings

- Aluminum veneer: Unveiling the charm of "invisible stars" in architecture

Industry dynamics

- Advantages and application areas of carved aluminum veneer on door heads

- The Beauty of Aluminum Ceiling: The Gorgeous Roofing of Modern Architecture

- The "honeycomb" mystery of aluminum honeycomb panels: revealing the lightweight responsibility of the modern building materials industry

- A drawing wall aluminum veneer solution created by a professional team

- Aluminum ceiling, creating a new trend of fashionable home furnishings

Frequently asked questions

- Can aluminum veneer achieve customized design?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Can aluminum veneer be used in the design of building arch bridges?

- How can aluminum veneer improve the appearance of buildings?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

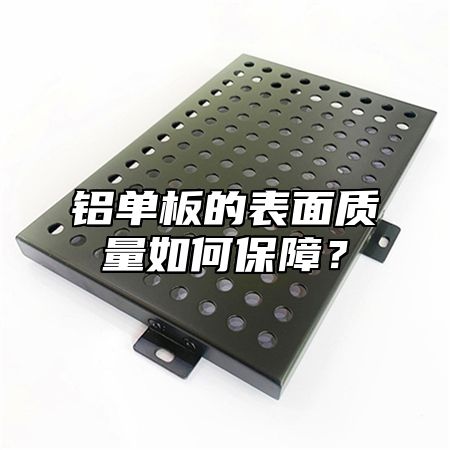

How to ensure the surface quality of aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 21, 2025 05:50:31

- Click:0

Aluminum veneerAs a common building material, its surface quality is one of the important considerations for customers when choosing to use this product. In order to ensure the surface quality of aluminum veneer, it is necessary to start from multiple aspects, including material selection, production process, surface treatment, and so on. This article will provide a detailed introduction to the surface quality assurance of aluminum veneer.

1、 Material selection

The material selection of aluminum veneer has a significant impact on its surface quality. Generally speaking, high-quality aluminum alloy sheets have high strength and hardness, which can ensure the surface flatness and durability of aluminum veneers. When purchasing aluminum veneer, it is necessary to choose high-quality aluminum alloy sheets produced by reputable manufacturers to ensure their surface quality.

2、 Production process

The production process of aluminum veneer is also one of the important factors affecting its surface quality. During the production process, it is necessary to pay attention to controlling factors such as temperature and humidity to avoid problems with aluminum veneer caused by overheating or undercooling. Attention should also be paid to controlling the processing speed and force to avoid problems such as deformation or cracking of aluminum veneer caused by excessive processing. The occurrence of these problems may affect the surface quality of aluminum veneer.

3、 Surface treatment

The surface treatment of aluminum veneer is also one of the important means to ensure its surface quality. At present, commonly used surface treatment methods include anodizing, electrophoretic coating, etc. These methods can form a dense oxide film or coating, enhancing the corrosion resistance and wear resistance of aluminum veneer, thereby improving its surface quality. Other surface treatment methods such as spraying, film sticking, etc. can also be used to further improve the surface quality of aluminum veneer.

4、 Selection of equipment and tools

The selection of equipment and tools during the production process can also affect the surface quality of aluminum veneer. For example, in anodizing treatment, it is necessary to choose a suitable electrolytic cell and power supply to ensure the electrolysis effect and the quality of the oxide film. In spraying treatment, it is necessary to choose suitable spraying equipment and coatings to ensure the spraying effect and coating quality. In the production process, it is necessary to pay attention to the selection of equipment and tools to improve the surface quality of aluminum veneer.

5、 Quality Management

Quality management is also one of the important means to ensure the surface quality of aluminum veneer. Enterprises need to establish a sound quality management system, strictly controlling every link from raw material procurement to production and processing to finished product inspection, to ensure that product quality meets standard requirements. It is also necessary to regularly inspect and maintain the production line, promptly identify and solve problems, to ensure the surface quality of aluminum veneer.

Ensuring the surface quality of aluminum veneer requires multiple aspects, including material selection, production process, surface treatment, equipment and tool selection, and quality management. Enterprises need to pay attention to product quality and service level, and actively respond to national environmental policies and requirements, providing customers with healthier and more environmentally friendly building decoration materials. The government also needs to strengthen the supervision and management of the aluminum veneer industry to promote its sustainable development.

Customer service QQ

Customer service QQ