Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum ceiling new trend: lightweight and fashionable, revitalizing indoor space

- The Beauty of Aluminum Ceiling: A Fashionable Choice for Creating Home Spaces

- The secret of honeycomb aluminum plate: as light as a feather, as solid as a rock

- Aluminum ceiling: a choice that emphasizes both fashion and practicality in modern architecture

Industry dynamics

- Aluminum veneer: the fashionable outerwear of modern architecture

- Honeycomb aluminum plate: What secrets are hidden behind its lightweight design?

- Aluminum veneer customization makes buildings more in line with people's aesthetic trends

- Aluminum curtain wall, a fashionable weapon in architecture

- Fluorocarbon aluminum veneer provides long-lasting protection for building exterior walls

Frequently asked questions

- How does the plasticity of aluminum veneer affect building comfort?

- What is the manufacturing process of aluminum veneer?

- How can aluminum veneer improve the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- How does the service life of aluminum veneer compare to other exterior wall materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the installation precautions for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 20, 2025 10:49:20

- Click:0

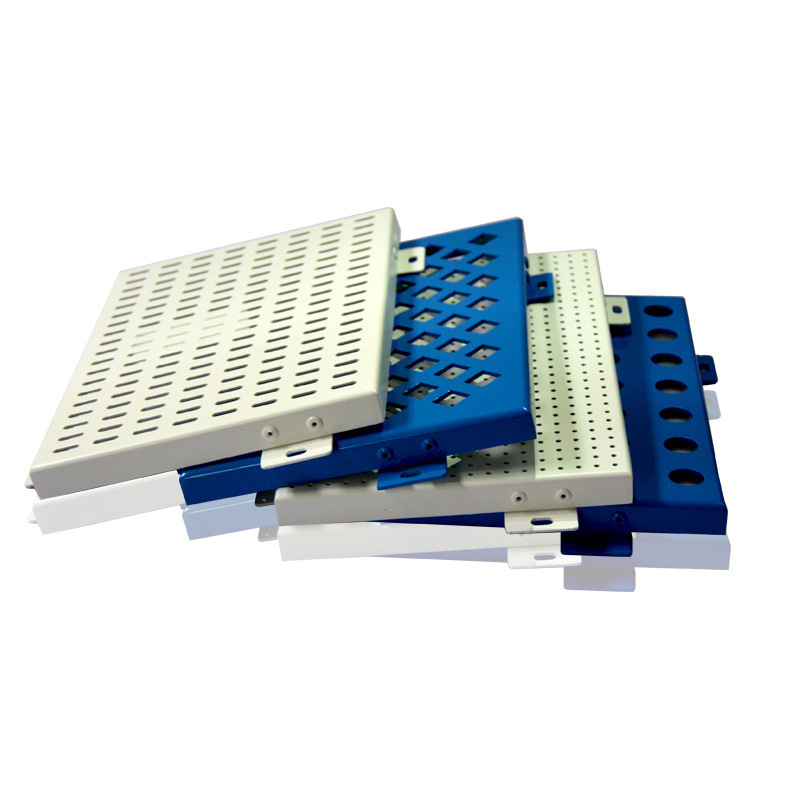

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its installation quality is one of the important factors affecting its service life and safety. The following will provide a detailed introduction to the installation precautions and importance of aluminum veneer.

1. Environmental requirements

The installation of aluminum veneer needs to be carried out in a suitable environment, generally requiring a temperature between 5 ° C-35 ° C and a relative humidity of no more than 85%. If the ambient temperature is too high or too low, it will affect the performance and service life of aluminum veneer; If the relative humidity is too high, it will cause water vapor to form on the surface of aluminum veneer, affecting its aesthetics and anti-corrosion performance. Before installation, it is necessary to check whether the surrounding environment meets the requirements and take corresponding measures to make adjustments.

1. Structural requirements

The installation of aluminum veneer requires a firm and smooth connection with the foundation structure. Before installation, the foundation structure should be inspected to ensure that its strength and stability meet the requirements. Attention should also be paid to the tilt angle and levelness of the aluminum veneer to ensure its flatness and aesthetic appearance after installation.

1. Keel requirements

The installation of aluminum veneer requires the use of keels for support, and the selection and installation quality of keels have a significant impact on the load-bearing capacity and stability of aluminum veneer. Generally speaking, the keel should be made of materials with high strength and good stability, such as aluminum alloy profiles, steel, etc; During installation, attention should be paid to the position and spacing of the keel to ensure that it can withstand the weight and load of the aluminum veneer.

1. Requirements for joint treatment

The joints of aluminum veneer are easily affected by external factors such as rain, sandstorms, etc., which can lead to cracking or detachment. Before installation, the joints should be treated by filling and sealing them with materials such as sealant or silicone to enhance their waterproofing and durability.

1. Safety precautions

During the installation process of aluminum veneer, safety issues need to be taken into account. For example, it is necessary to wear protective equipment such as helmets and gloves to avoid injury; Pay attention to the use and storage of tools to avoid injuring others or damaging equipment; Attention should be paid to the cleanliness of the construction site and the setting of safe passages to ensure the safety of construction personnel.

The installation precautions for aluminum veneer include environmental, structural, keel, joint treatment, and safety aspects. Enterprises should choose appropriate installation plans based on actual situations and strictly follow installation requirements for operation and evaluation to ensure product quality and safety.

Customer service QQ

Customer service QQ