Industry information

Company News

- Aluminum veneer customization: the perfect combination of personality and quality

- Aluminum curtain wall: the beauty of architecture, the soul of details

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new proposition for personalized space!

- Aluminum ceiling: poetic embellishment of modern space

Industry dynamics

- Aluminum ceiling: the fashionable new favorite of modern architecture

- Aluminum honeycomb panel: lightweight and sturdy, the new darling of construction!

- A drawing wall aluminum veneer solution created by a professional team

- Customized aluminum veneer, creating personalized space and new fashion

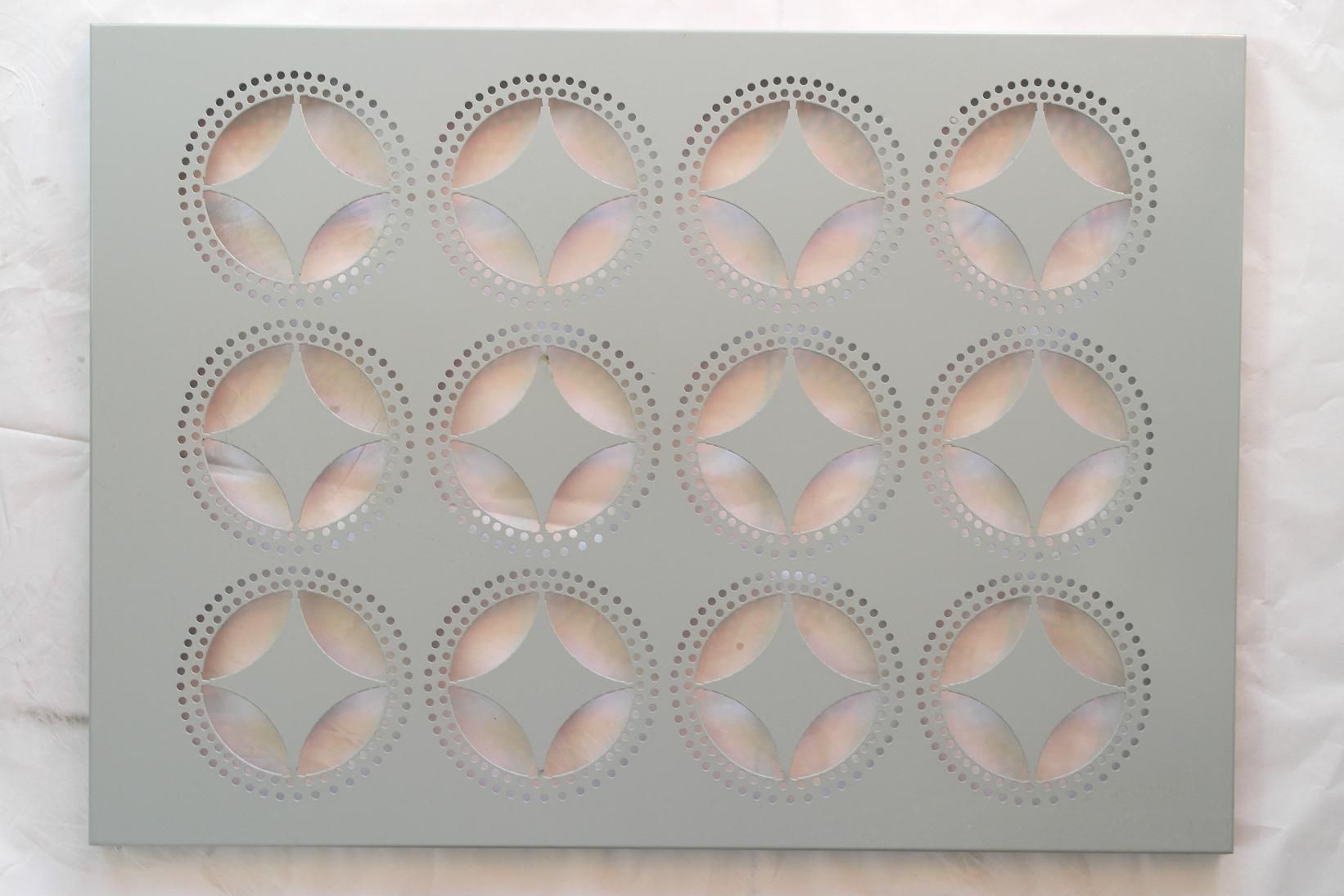

- Carved exterior aluminum veneer is an innovative material that breaks through traditional architectural appearance

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- Has the production process of aluminum veneer reduced energy consumption?

- How can aluminum veneer improve the appearance of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Is the surface treatment of aluminum veneer durable?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer manufacturer's product quality standards

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 19, 2025 06:35:32

- Click:0

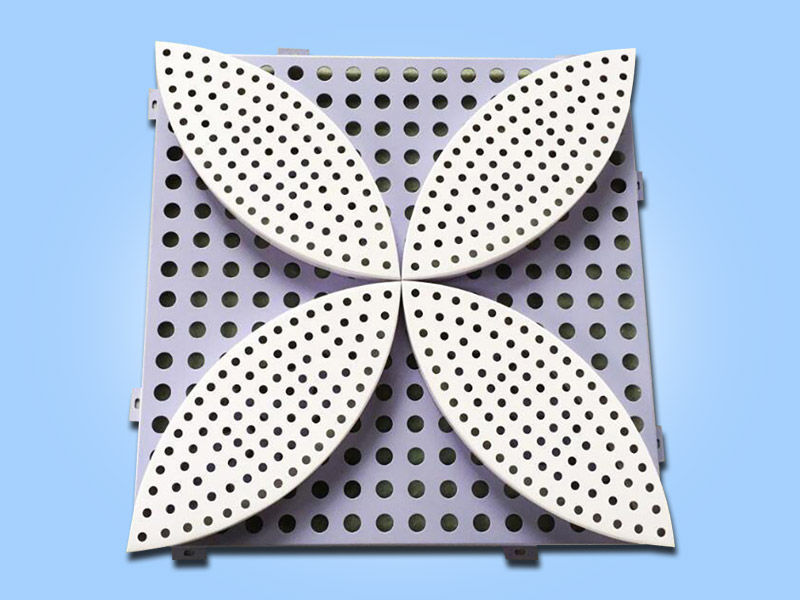

Aluminum veneerAs a building decoration material, product quality is one of the important factors for customers to choose. Below is a detailed introduction to the product quality standards of aluminum veneer manufacturers.

1、 Raw material quality

1. Aluminum: Aluminum is the main raw material for aluminum veneer, and high-quality aluminum that meets national standards should be selected.

2. Surface treatment: The surface treatment of aluminum veneer includes spraying, anodizing, powder coating, etc., and surface treatment methods and materials that comply with national standards should be selected.

3. Auxiliary materials: The auxiliary materials for aluminum veneer include keel, sealant, etc., and materials that meet national standards should be selected.

2、 Production process

1. Equipment requirements: The production of aluminum veneer requires the use of advanced processing equipment that meets the requirements of national standards.

2. Technical requirements: The production of aluminum veneer requires a professional technical team and patented technology with independent intellectual property rights to enhance the competitiveness of the product.

3、 Quality Assurance System

1. ISO certification: Aluminum veneer manufacturers should obtain ISO certification to demonstrate that the quality and performance of their products meet international standard requirements.

2. Quality control: Aluminum veneer manufacturers should establish a comprehensive quality control system to ensure stable and reliable product quality.

4、 After sales service

1. Warranty period: Aluminum veneer manufacturers should provide a reasonable warranty period for their products to protect the rights and interests of customers.

2. Maintenance: Aluminum veneer manufacturers should provide comprehensive after-sales service to ensure timely repair and maintenance during the use of aluminum veneer.

3. Customer feedback: Aluminum veneer manufacturers should promptly pay attention to customer feedback and solve the problems and needs encountered by customers during use.

5、 Environmental protection and energy conservation

1. Energy conservation and emission reduction: Aluminum veneer manufacturers should adopt energy-saving and emission reduction technologies and management measures to reduce energy consumption and environmental pollution during the production process.

2. Recyclability: Aluminum veneer manufacturers should pay attention to the recyclability of their products and reduce their impact on the environment.

The product quality standards of aluminum veneer manufacturers include aspects such as raw material quality, production process, quality assurance system, after-sales service, and environmental protection and energy conservation. In the actual operation process, it is necessary to follow relevant norms and standards for operation and management, strengthen communication and collaboration, and improve work efficiency and quality level. We also need to pay attention to issues such as environmental protection and energy conservation, continuously innovate and improve products and services, and meet the needs of customers and the expectations of society.

Customer service QQ

Customer service QQ