Industry information

Company News

- Aluminum Ceiling: The New Favorite of Modern Home Furnishings, a Perfect Fusion of Fashion and Practicality

- Aluminum curtain wall, the fashionable 'outerwear' in modern architecture

- Aluminum curtain wall: the fashionable new darling of the construction industry

- 2. Customize aluminum veneer to give your home more face. 3 Customized aluminum veneer, design your

- The wonderful world of aluminum honeycomb panels: the perfect combination of lightness and strength

Industry dynamics

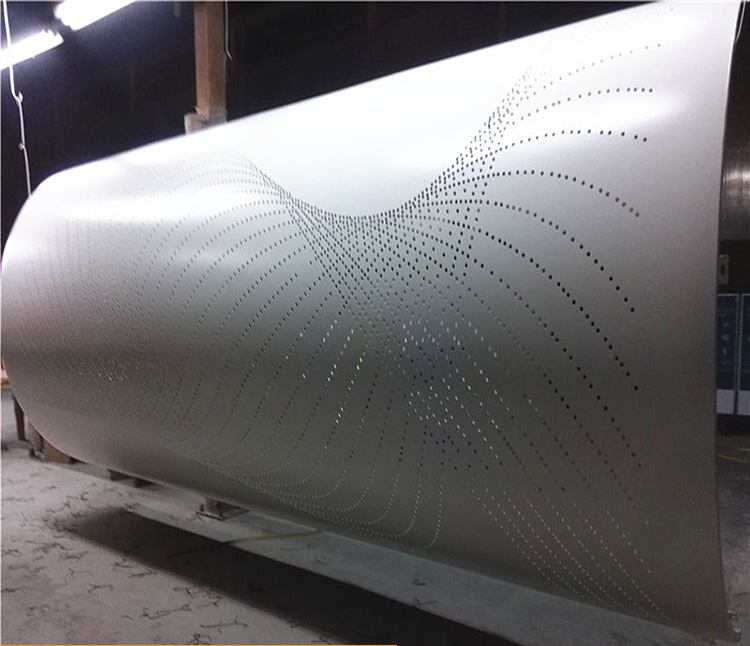

- Carving and carving aluminum veneer with unique architectural materials

- How economical is aluminum veneer in architectural exterior design?

- Aluminum honeycomb panel: the 'secret weapon' of modern architecture

- How strong is the color durability of aluminum veneer?

- Aluminum ceiling, creating a new trend of fashionable home furnishings

Frequently asked questions

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Is the surface treatment of aluminum veneer durable?

- How can aluminum veneer improve the appearance of buildings?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

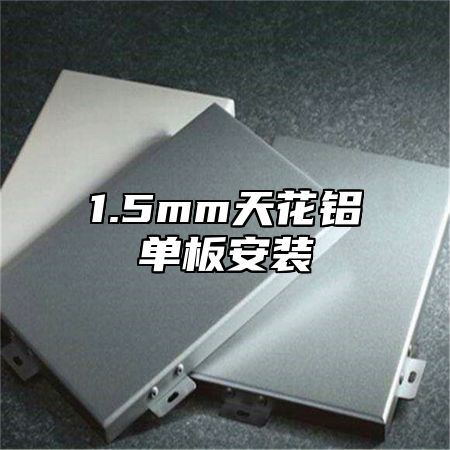

Installation of 1.5mm ceiling aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-16 07:29:38

- Click:0

1.5mm ceilingAluminum veneerThe installation is an important part of ensuring its service life and aesthetics. This article will provide a detailed introduction to the installation steps and precautions for 1.5mm ceiling aluminum veneer.

1、 Preparation before installation

1. Check the construction site to ensure that the ground is flat, without obvious unevenness, and the walls are free of oil stains, debris, etc.

2. Measure the required size and quantity of 1.5mm ceiling aluminum veneer according to the design drawings and actual needs.

3. Prepare necessary tools and materials, such as drills, hammers, screwdrivers, cutting machines, as well as keels, hangers, and lifting devices.

2、 Installation steps

1. Making keel: According to design requirements, keel is made on the ground or wall, usually using aluminum alloy keel or steel keel, and the specific choice depends on the actual situation.

2. Install the suspension rod: Fix the suspension rod on the keel, and adjust the length of the suspension rod according to actual needs.

3. Installation of lifting components: Connect the lifting components to the suspension rod and fix them with screws.

4. Install 1.5mm ceiling aluminum veneer: Place the 1.5mm ceiling aluminum veneer on the hanger and fix it with screws.

5. Cleaning work: After installation, clean the site to ensure that there are no residues.

3、 Precautions

1. Pay attention to safety during installation to avoid accidents.

2. When making keels and hangers, attention should be paid to size and accuracy to ensure installation effectiveness.

3. When installing 1.5mm ceiling aluminum veneer, attention should be paid to levelness and verticality to ensure overall aesthetics.

4. After installation, acceptance should be carried out to ensure compliance with design requirements and quality standards.

The installation of 1.5mm ceiling aluminum veneer is an important step in ensuring its service life and aesthetic appearance. Only by strictly following the relevant installation guidelines and operating procedures can the installation quality and effectiveness be guaranteed. We also need to strengthen communication and cooperation with customers, understand their needs and feedback, continuously optimize products and services, and enhance market competitiveness.

Customer service QQ

Customer service QQ