Industry information

Company News

- Aluminum veneer: understated luxury in modern architecture

- Aluminum veneer, a low-key star in modern architecture

- Aluminum veneer customization, creating an exclusive personalized space

- The fashion code of aluminum veneer: Unveiling the beauty of modern architecture

- Aluminum Ceiling: The Fresh "Top" Choice for Modern Home Furnishings

Industry dynamics

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer customization, creating a new trend of personalized space

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock

- Aluminum veneer on walls and exterior walls makes buildings safer and more aesthetically pleasing

- Aluminum ceiling: the new darling of modern home decoration

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- How can aluminum veneer improve the appearance of buildings?

- How does the plasticity of aluminum veneer affect building comfort?

- Can aluminum veneer be used in the design of building arch bridges?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Sharing of Construction Techniques for 2.0mm Ceiling Aluminum Single Panel

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 12, 2025 14:05:20

- Click:0

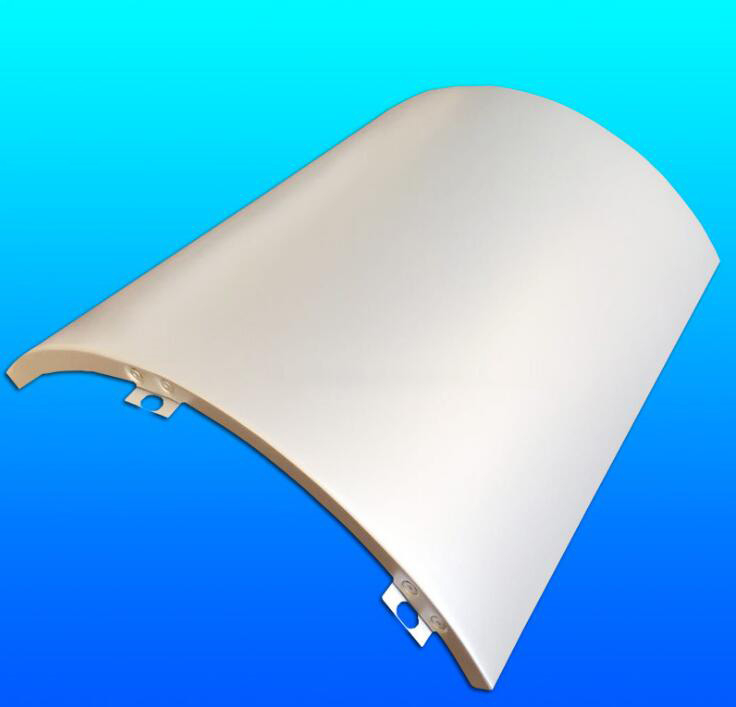

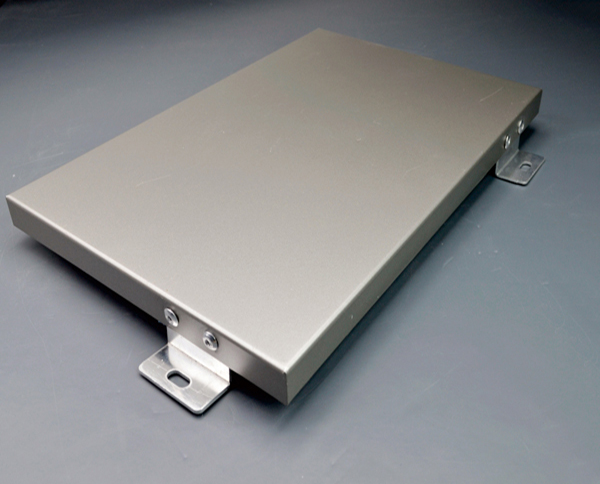

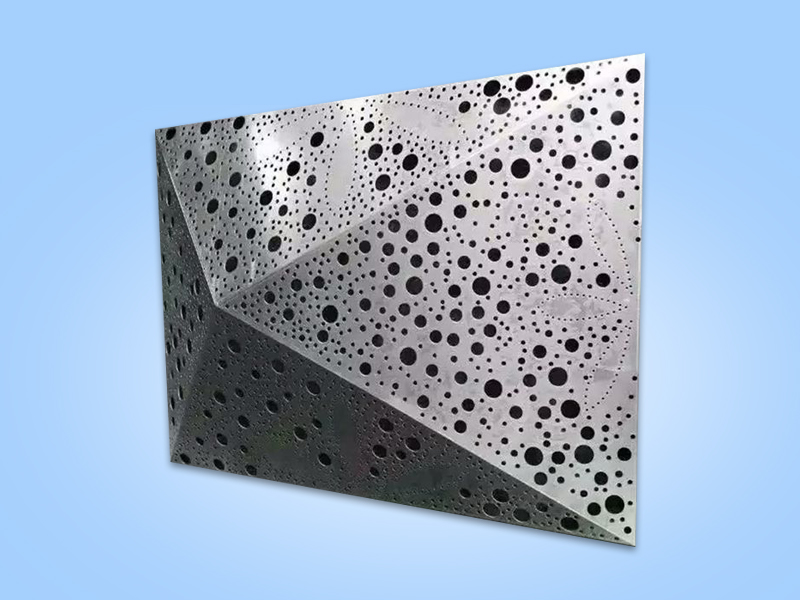

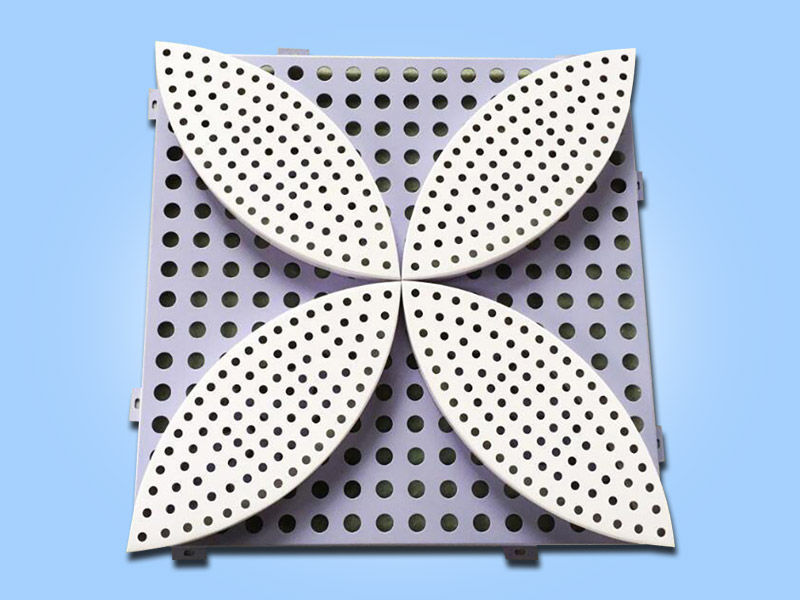

2.0mm ceilingAluminum veneerIt is a high-quality and high-performance decorative material widely used in the interior decoration of commercial centers, office buildings, hotels, hospitals, schools and other buildings. It has excellent appearance and decorative performance, but construction techniques are also one of the key factors affecting its final effect. This article will provide a detailed introduction to the construction techniques of 2.0mm ceiling aluminum veneer from the aspects of preparation before construction, precautions during installation, and post construction treatment.

1、 Preparation before construction

1. Determine the construction plan: Before starting construction, a detailed construction plan needs to be developed based on the customer's needs and design requirements, including material selection, size measurement, and installation location.

2. Material inspection: Before starting construction, it is necessary to inspect the selected 2.0mm ceiling aluminum veneer to ensure that the quality of the material meets the requirements and there are no obvious defects or deficiencies.

3. Prepare tools and equipment: According to the requirements of the construction plan, prepare the necessary tools and equipment, such as electric drills, cutting machines, level gauges, etc.

2、 Precautions during installation

1. Measurement of dimensions: Before installing the 2.0mm suspended aluminum panel, a spirit level needs to be used to measure the installation position to ensure that the installation height and levelness of the aluminum panel meet the design requirements.

2. Cutting aluminum veneer: Based on the measurement results, use an electric drill and cutting machine to cut the 2.0mm ceiling aluminum veneer into the required size and shape.

3. Installation of keel: Before installing the 2.0mm ceiling aluminum veneer, it is necessary to install the keel first to ensure the stability and load-bearing capacity of the aluminum veneer.

4. Installation of aluminum veneer: Fix the cut 2.0mm ceiling aluminum veneer in the installation position through the keel, and pay attention to the smooth joints between the aluminum veneers, without obvious height differences.

5. Joint treatment: Leave a certain joint between aluminum veneers for subsequent treatment and repair.

3、 Post construction handling

1. Cleaning the site: After completing the installation of 2.0mm suspended aluminum panels, it is necessary to clean the construction site to maintain a clean environment.

2. Joint treatment: Apply sealant or silicone at the joint between aluminum veneers to prevent rainwater from seeping in and protect the surface of the aluminum veneer from damage.

3. Quality inspection: After the construction is completed, it is necessary to inspect the quality of the 2.0mm ceiling aluminum veneer to ensure that its installation height, levelness, and stability meet the design requirements.

The construction technique of 2.0mm suspended aluminum veneer is one of the key factors to ensure its final effect. Only by making sufficient preparations before construction and paying attention to details and handling joints during installation can the aesthetics and service life of aluminum veneer be guaranteed. Proper treatment and maintenance are also required after construction to ensure its long-term stable decorative effect.

Customer service QQ

Customer service QQ