Industry information

Company News

- The Light of Aluminum Curtain: The New Favorite of Modern Architecture

- Aluminum veneer: the "invisible" guardian of modern architecture

- Aluminum ceiling: simple yet not simple, creating a new trend of modern space

- The secret of honeycomb aluminum plate: lightweight and high-strength, the new favorite of future industry

- Aluminum curtain wall: the fashionable new favorite of urban architecture

Industry dynamics

- Aluminum ceiling: the new darling of creating fashionable spaces!

- Customized aluminum veneer adds artistic flair to buildings

- Aluminum ceiling, the elegant choice in modern architecture

- Aluminum ceiling: not just decoration, but also the new darling of smart buildings!

- Development of Collaborative Management for Customized Design and Construction of Aluminum Veneer

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- Can aluminum veneer achieve customized design?

- What is the manufacturing process of aluminum veneer?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Exploring the Quality Assurance of Aluminum Veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-22 20:45:41

- Click:0

Aluminum veneerAs a new type of building material, it has the characteristics of lightweight, corrosion resistance, fire resistance, environmental protection, and aesthetics, and is widely used in the field of building decoration. With the increasing market demand, quality assurance of aluminum veneer has become increasingly important. Below, we will provide a detailed introduction to the quality assurance measures for aluminum veneer.

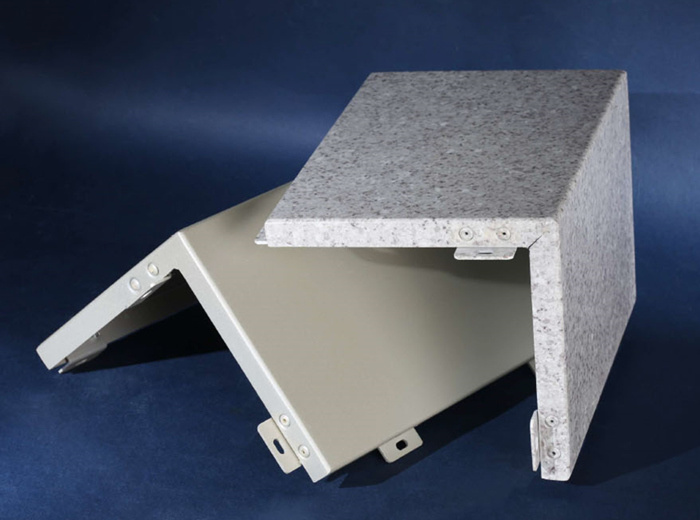

1、 Raw material procurement

The quality of aluminum veneer is closely related to the quality of raw materials. When purchasing raw materials, high-quality aluminum manufacturers should be selected, and strict inspection and testing should be conducted on the raw materials. Only by ensuring stable and reliable quality of raw materials can the quality of aluminum veneer be guaranteed.

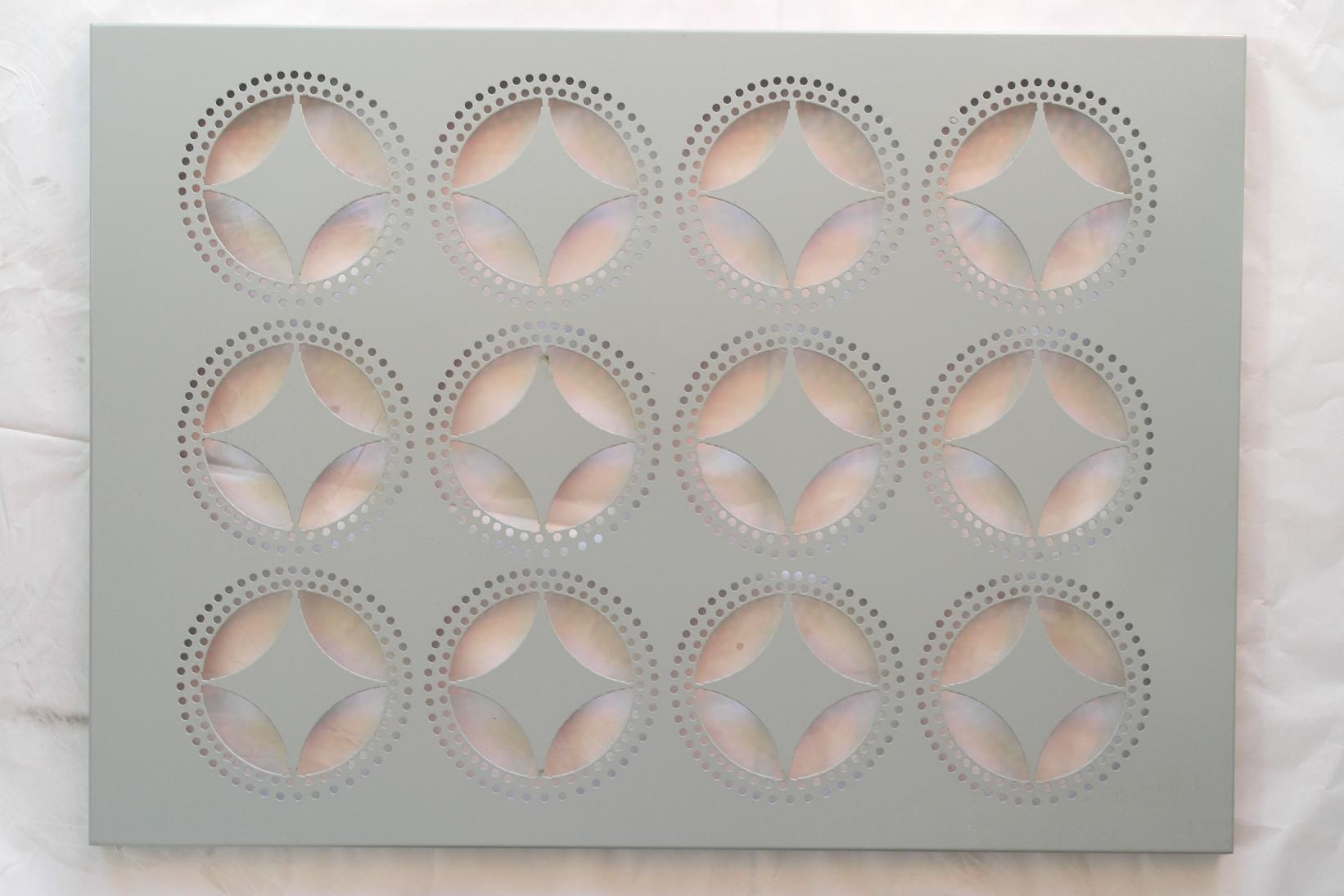

2、 Production process control

Production process is one of the important factors affecting the quality of aluminum veneer. In the production process, advanced production techniques and equipment should be adopted to ensure that every step meets the standard requirements. We should also strengthen the monitoring and management of the production process, timely discover and solve problems in production, and ensure the quality of aluminum veneer.

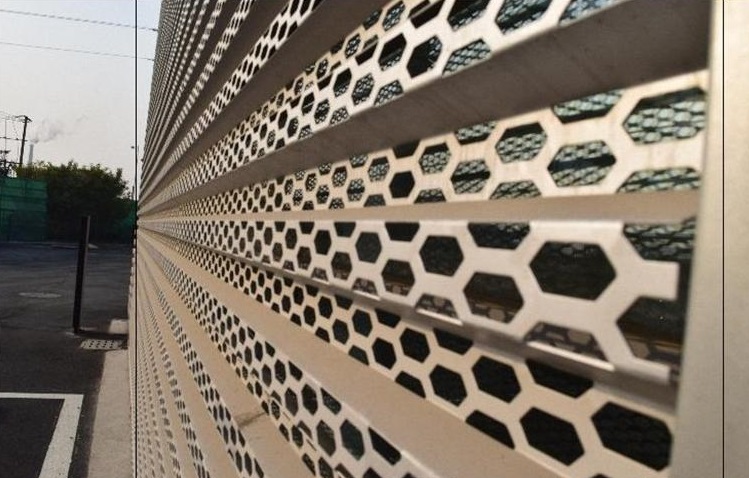

3、 Surface treatment technology

Surface treatment technology is one of the important factors affecting the appearance of aluminum veneer. In the surface treatment process, advanced technology and equipment should be used to ensure that every step meets the standard requirements. We should also strengthen the monitoring and management of the surface treatment process, strictly control the quality and effectiveness of surface treatment, and ensure the quality of aluminum veneer.

4、 Quality inspection

Quality inspection is one of the key links to ensure the quality of aluminum veneer. In the production process, a comprehensive quality inspection system should be established to conduct strict testing and inspection at every stage. We should also strengthen the sampling and third-party testing of finished products to ensure that the quality of aluminum veneer meets national standards and user needs.

5、 After sales service

After sales service is one of the important means to ensure customer satisfaction. After sales, it is necessary to promptly respond to customer feedback and complaints, and actively solve problems encountered by customers. We should also establish a comprehensive after-sales service system to provide customers with high-quality after-sales service, enhance their trust and loyalty.

The above five aspects are one of the main quality assurance measures in the current aluminum veneer industry. In the future, with people's increasing demands for building decoration, the aluminum veneer industry will continue to develop towards higher end, intelligent, green and diversified directions.

Customer service QQ

Customer service QQ