Industry information

Company News

- Aluminum veneer: the "silver garment" of modern architecture

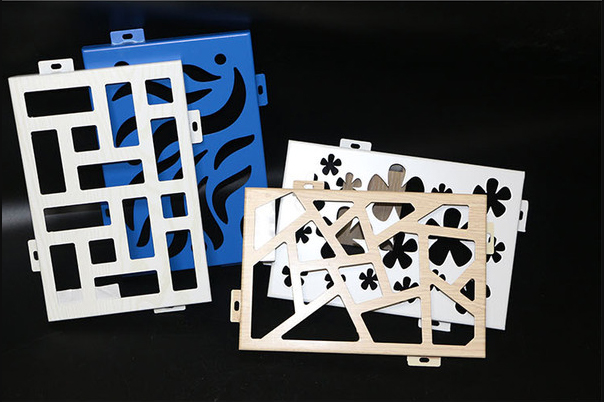

- Aluminum veneer customization, creating an exclusive personalized space

- Aluminum curtain wall: the fashionable "coat" of modern architecture

- Aluminum ceiling, creating a new trend of modern space

- Aluminum veneer customization, creating an exclusive fashion space!

Industry dynamics

- Classic Return to Wave 2.0mm Aluminum Veneer Interprets Architectural Aesthetics

- Wave ceiling aluminum veneer showcases the perfect combination of aesthetics and practicality in architecture

- Aluminum ceiling: a perfect combination of architectural aesthetics and practicality

- Honeycomb Aluminum Plate: Unveiling the Light Luxury Secrets of Modern Architecture

- Aluminum curtain wall, the fashionable coat of modern architecture

Frequently asked questions

- What is the manufacturing process of aluminum veneer?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer be used in the design of building arch bridges?

- How does the service life of aluminum veneer compare to other exterior wall materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The counterattack of honeycomb aluminum plate: the secret behind its lightness

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 3, 2025 14:34:16

- Click:0

Friends, today let's talk about a seemingly ordinary but actually extraordinary material - honeycomb aluminum plate. You may think it's just a synonym for "lightness", but did you know that its path of counterattack is full of technology and mystery!

Honeycomb aluminum plate, this name sounds a bit fancy, but in fact, its origin is quite down-to-earth. As early as the 1950s, an engineer in the United States accidentally discovered that honeycomb structures had excellent load-bearing and impact resistance performance while studying aircraft structures. Honeycomb aluminum panels emerged as a result.

When it comes to honeycomb aluminum panels, the first thing to talk about is their "lightness". Do you know that the density of honeycomb aluminum plate is only 1/3 of steel, but its weight can reach 2/3 of the same thickness of steel plate. Does it sound magical? It's like a person weighing 200 pounds suddenly becoming 70 pounds, does that feel much easier instantly?

The lightweight of honeycomb aluminum plate is not only due to its low density, but also because of its structure. Honeycomb aluminum plate adopts a honeycomb structure, which can stretch and contract like a spring when subjected to pressure, thereby reducing damage caused by collisions or impacts. It's like a person's body can stretch and contract like a spring when wrestling, reducing the risk of injury.

What are the application areas of honeycomb aluminum plates? You may not believe it, but the application range of honeycomb aluminum sheet is very wide, covering almost every aspect of our lives.

Honeycomb aluminum plates have a wide range of applications in the aerospace industry. Aircraft, missiles, satellites, etc. all rely on honeycomb aluminum panels. Because it is lightweight and durable, it can help aircraft reduce weight, improve fuel efficiency, and enhance safety.

In the field of automobile manufacturing, honeycomb aluminum plates are also highly favored. The body, doors, roof and other parts of the car are all made of honeycomb aluminum panels. This can not only reduce the weight of the vehicle, improve fuel efficiency, but also enhance the impact resistance of the car.

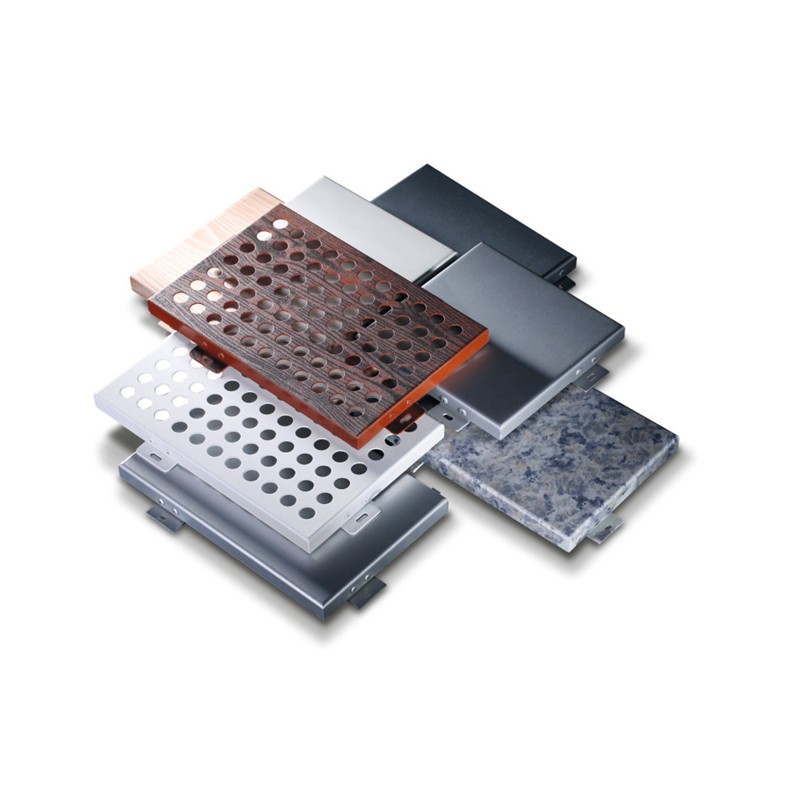

Honeycomb aluminum panels also have important applications in the field of construction. Honeycomb aluminum panels can be used to make exterior wall panels, ceilings, partitions, etc. of buildings. This can not only improve the stability of buildings, but also reduce construction costs.

How is honeycomb aluminum plate made? This brings up a technology called 'honeycomb forming'. Honeycomb forming technology is to press aluminum plates into honeycomb shapes through molds, and then weld or bond them. This process may seem simple, but it actually requires a high level of technical expertise.

I want to share a little story. I remember once I visited a factory and saw the production process of honeycomb aluminum panels. At that time, I was saying to a worker master, 'Master, your skills are really amazing!' The master replied with a smile, 'It's nothing, the key is to put in the effort to do it.' Hearing this, I deeply resonated.

Honeycomb aluminum plate, this seemingly ordinary material, contains endless technological power behind it. It is lightweight and durable, bringing many conveniences to our lives. Perhaps one day in the future, honeycomb aluminum panels will become an indispensable part of our lives.

I want to say that technology changes lives, and innovation leads the future. Let's look forward together to the more surprises and possibilities that honeycomb aluminum panels will bring us in the future. After all, this world is full of infinite possibilities!

Customer service QQ

Customer service QQ