Industry information

Company News

- Aluminum veneer: the new darling of modern architecture. How much do you know about it?

- Aluminum ceiling: not just a ceiling, but also a dual combination of fashion and practicality

- Aluminum veneer customization, creating a new trend of personalized space

- Honeycomb aluminum plate: lightweight and extraordinary, the new favorite of architecture!

- Aluminum veneer: not just sheet metal, but also the soul of modern architecture

Industry dynamics

- What is the dustproof performance of fluorocarbon aluminum veneer?

- The secret of aluminum honeycomb panels: as light as feathers, as strong as rocks!

- Aluminum honeycomb panel: the technological secret behind its lightweight design

- Carving and carving aluminum veneer with unique architectural materials

- Aluminum curtain wall, a shining pearl in modern architecture

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- What is the manufacturing process of aluminum veneer?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer be used in the design of building arch bridges?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the manufacturing process of hyperbolic aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-22 08:30:14

- Click:0

hyperbolicAluminum veneerIt is a building material made of aluminum alloy sheet through special processing technology, which has the advantages of lightweight, high strength, and corrosion resistance. What is the manufacturing process of hyperbolic aluminum veneer? Below is a detailed introduction for everyone.

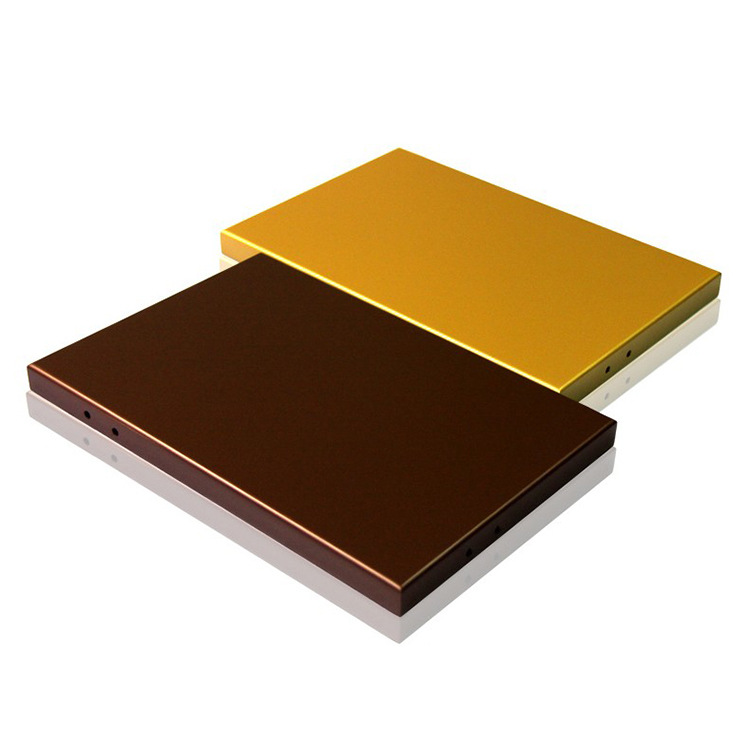

The manufacturing process of hyperbolic aluminum veneer mainly includes multiple steps such as raw material procurement, cutting, stamping, CNC cutting, rolling forming, anodizing, etc. Raw material procurement is the foundation of the entire manufacturing process, requiring the selection of aluminum alloy materials with good quality and performance. Then, the raw materials are subjected to a flattening process to make them into aluminum plates with uniform thickness. Then, it is processed into hyperbolic aluminum veneer of the desired shape and size through stamping, CNC cutting, and other methods. Finally, surface treatment of hyperbolic aluminum veneer is carried out through rolling forming and anodizing to improve its decorative and durability properties.

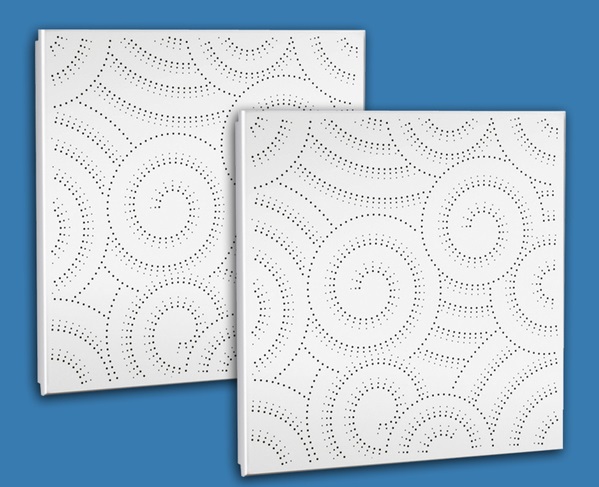

Different types of hyperbolic aluminum veneer also have different manufacturing processes. For example, single hyperbolic aluminum veneer is usually processed directly from flat sheet metal; Hyperbolic aluminum veneer requires multiple processing and treatment to obtain the desired shape and size. There are also some special hyperbolic aluminum veneers, such as honeycomb hyperbolic aluminum veneers, which require special production processes and equipment for manufacturing.

Once again, manufacturing hyperbolic aluminum veneer requires attention to some technical details. For example, in processes such as stamping and CNC cutting, it is necessary to control the force and accuracy to ensure that the hyperbolic aluminum veneer produced meets the design requirements; Strict control of temperature and time is also required during processes such as rolling forming and anodizing to achieve good surface effects. Attention should also be paid to the selection of raw materials and quality control to ensure that the manufactured hyperbolic aluminum veneer has good quality and performance.

Finally, it should be noted that corresponding environmental protection measures should be taken when manufacturing hyperbolic aluminum veneer to avoid environmental pollution. For example, in the procurement and processing of raw materials, attention should be paid to selecting environmentally friendly materials and equipment, and strengthening the recycling and utilization of waste. During the production process, attention should also be paid to reducing the discharge of pollutants such as exhaust gas and wastewater, in order to protect the environment and human health.

The manufacturing process of hyperbolic aluminum veneer includes multiple steps such as raw material procurement, cutting, stamping, CNC cutting, rolling forming, anodizing, etc. Different types of hyperbolic aluminum veneer also have different manufacturing processes, and some technical details need to be paid attention to. We should closely monitor the latest developments and application cases of hyperbolic aluminum veneer technology, and actively promote the application and development of hyperbolic aluminum veneer in various fields. During the application process, attention should be paid to construction quality and safety issues to avoid potential safety hazards and quality problems.

Customer service QQ

Customer service QQ