Industry information

Company News

- Aluminum curtain wall: the beauty of architecture, the soul of details

- Aluminum veneer: the "green clothing" of modern architecture

- Aluminum curtain wall: the beauty of architecture, the light of technology

- Aluminum veneer: the beauty of industry, simple yet not simple

- Customized aluminum veneer, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer: the secret to creating fashionable buildings

- Honeycomb aluminum plate: the technological secret behind its lightweight design

- How is the market reaction to aluminum veneer?

- The fashionable variation of aluminum veneer, the elegant choice of modern architecture

- Cost and benefit analysis of aluminum veneer installation

Frequently asked questions

- Is the surface treatment of aluminum veneer durable?

- How can aluminum veneer improve the appearance of buildings?

- How does the plasticity of aluminum veneer affect building comfort?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- What is the manufacturing process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and technology of architectural stone patterned aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 15, 2025 03:45:20

- Click:0

Architectural stone patternAluminum veneerIt is a new type of building material with unique characteristics in its manufacturing process and technology. The following will be introduced from the following aspects:

1. Selection of raw materials

The main raw materials for architectural stone patterned aluminum veneer are aluminum alloy and surface treatment materials. Aluminum alloys are usually used in series such as 1100, 3003, 5052, which have high strength and hardness, as well as good corrosion resistance. Surface treatment materials include fluorocarbon paint, polyester paint, powder coating, etc., which can provide different decorative and protective effects.

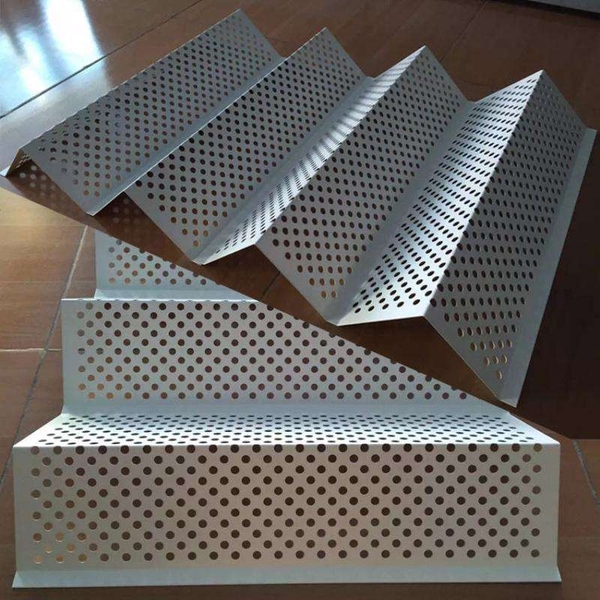

2. Cutting and punching

Before making architectural stone patterned aluminum veneer, it is necessary to first cut and punch the aluminum alloy sheet. This process requires the use of professional equipment and technology to ensure the quality and accuracy of cutting and punching. It is also necessary to select holes of appropriate size and shape according to design requirements and actual needs.

3. Surface treatment

The surface treatment of architectural stone patterned aluminum veneer is a very important step in its production process. This process usually includes various methods such as spraying, roller coating, and heat transfer printing to provide different decorative and protective effects. Fluorocarbon paint is the most commonly used surface treatment material, which has excellent weather resistance and corrosion resistance, and can provide long-lasting decorative and protective effects.

4. Welding and assembly

The production of architectural stone patterned aluminum veneer also requires welding and assembly work. In this process, professional equipment and technology are required to ensure the quality and accuracy of welding. It is also necessary to choose appropriate connection methods and structural forms based on design requirements and actual needs.

The production process and technology of architectural stone patterned aluminum veneer have unique characteristics, including multiple stages such as raw material selection, cutting and punching, surface treatment, welding, and assembly. These processes require the use of professional equipment and technology to ensure the quality and accuracy of the product. With the continuous advancement and development of technology, the application prospects of architectural stone patterned aluminum veneer will also become increasingly broad.

Customer service QQ

Customer service QQ