Industry information

Company News

- New trend of aluminum curtain: the beauty of architecture lies in the lightness of one scene

- The magical charm of aluminum honeycomb panels: a lightweight and sturdy secret weapon!

- Aluminum ceiling: poetic embellishment of modern space

- Aluminum veneer customization, creating a new trend of personalized space

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

Industry dynamics

- Analysis of Marketing Channels for Aluminum Veneer Manufacturers

- The secret of honeycomb aluminum plate: as light as a feather, as solid as a rock

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Aluminum Curtain Wall: The 'Gorgeous Coat' of Modern Architecture

- Aluminum veneer customization, creating a new proposition for personalized space

Frequently asked questions

- How does the plasticity of aluminum veneer affect building comfort?

- What is the manufacturing process of aluminum veneer?

- Can aluminum veneer achieve customized design?

- How can aluminum veneer improve the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

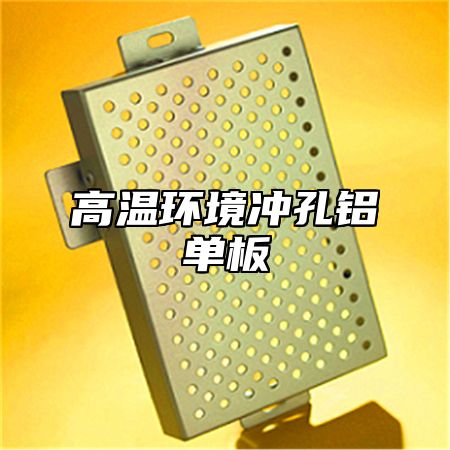

High temperature environment punching aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-09 05:28:39

- Click:0

With the development of the construction industry, the demand for building materials in high-temperature environments is increasing. punchingAluminum veneerAs a commonly used building material, it also has a wide range of applications in high-temperature environments. How to choose and use perforated aluminum veneer in high temperature environments? Below is a detailed introduction.

1、 Material requirements

In high-temperature environments, perforated aluminum veneer needs to have good high-temperature resistance. When selecting, it is necessary to choose materials with high temperature resistance. Generally speaking, aluminum alloy is one of the main materials for making punched aluminum veneers, and in high-temperature environments, it is necessary to choose aluminum alloy materials with higher temperature resistance. It is also necessary to consider the material used for surface treatment of punched aluminum veneer, such as anodizing, which also needs to have a certain degree of high temperature resistance.

2、 Thickness requirements

In high temperature environments, perforated aluminum veneer needs to have sufficient thickness to withstand the effects of high temperature conditions. Generally speaking, the thicker the punched aluminum veneer, the better its high-temperature resistance performance. However, excessively thick punched aluminum veneer will increase the weight and cost of the building, so it needs to be selected according to the actual situation.

3、 Surface treatment requirements

Surface treatment of punched aluminum veneer is also very important in high-temperature environments. Common surface treatment methods include anodizing, electrophoretic coating, etc. These processing methods can improve the surface hardness and wear resistance of punched aluminum veneer, while also endowing it with different colors and coatings to meet different decorative needs. In high-temperature environments, it is necessary to choose surface treatment methods with good heat resistance.

4、 Installation requirements

Special attention should also be paid to the installation of punched aluminum veneer in high-temperature environments. Attention should be paid to the fixing method of punched aluminum veneer, which is generally fixed by welding or riveting. Attention should be paid to the sealing between punched aluminum panels and buildings to prevent heat from entering the interior of the building through gaps. Attention should be paid to the maintenance of punched aluminum veneer, timely cleaning and replacement of aging components to ensure its normal service life and function.

5、 Case sharing

The following is a successful case of using perforated aluminum veneer in a high-temperature environment: a high-rise building's exterior wall used perforated aluminum veneer as a decorative material, and after scientific design and construction management, the installation work was successfully completed. This building not only improves its appearance and practicality, but also conforms to the environmental protection concept of modern society. This application solution has set an example for the development of the industry.

Punched aluminum veneer in high-temperature environments requires good high-temperature resistance, sufficient thickness, suitable surface treatment methods, as well as correct installation methods and maintenance measures. Only through scientific selection methods and strict construction management can its advantages be fully utilized to improve the safety and aesthetics of buildings.

Customer service QQ

Customer service QQ