Industry information

Company News

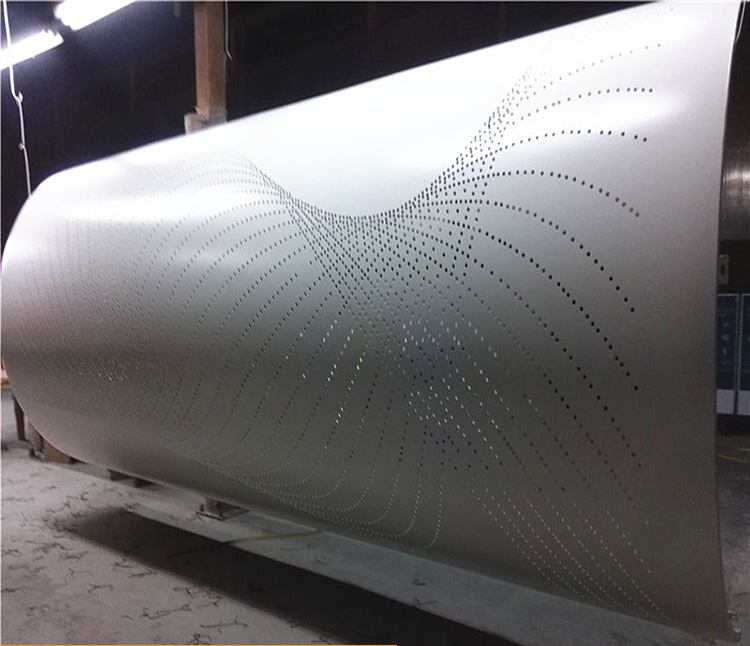

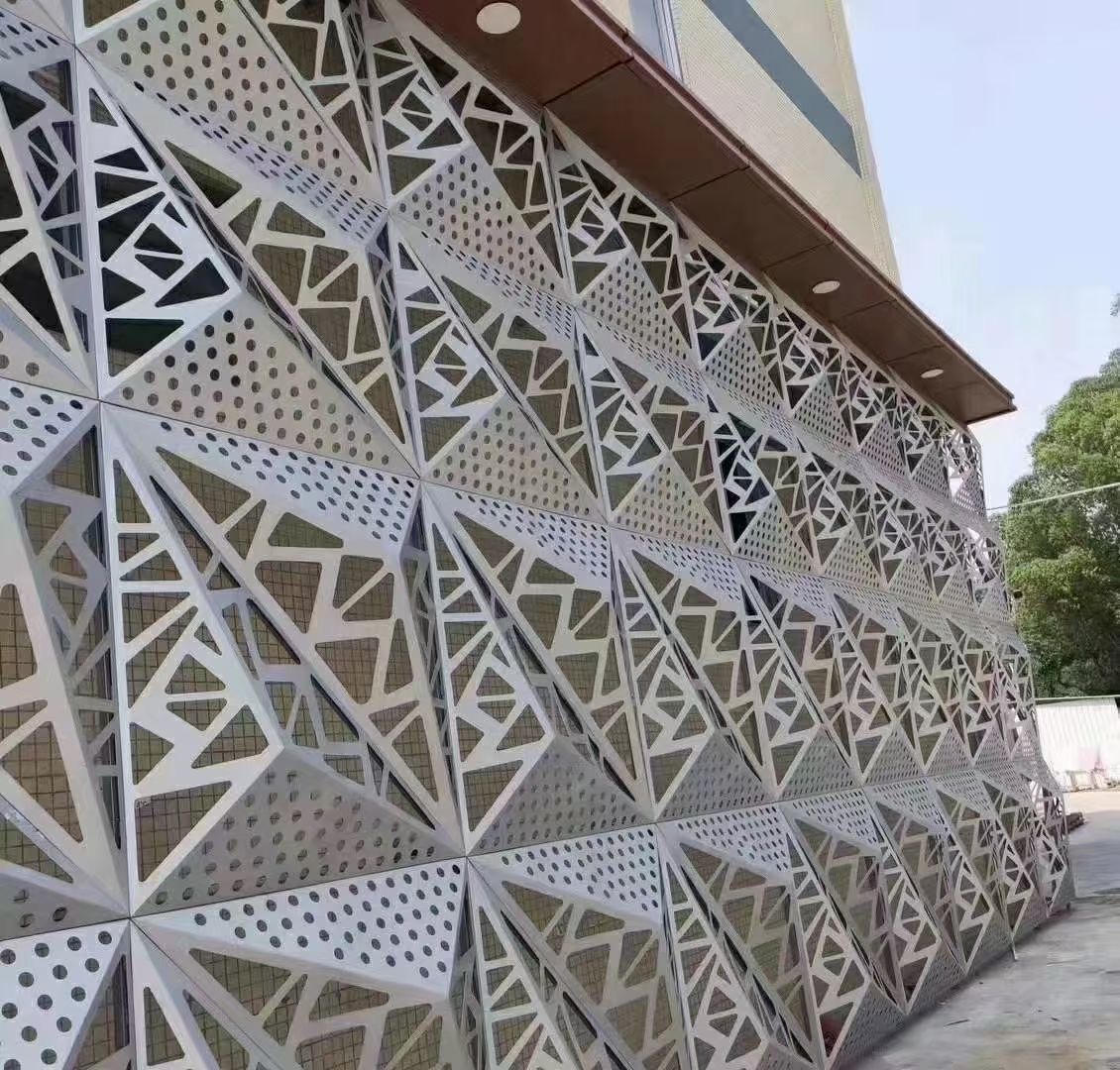

- Aluminum veneer: not just sheet metal, but also the soul of modern architecture

- Aluminum veneer: a unique language of architectural aesthetics

- The mystery of aluminum honeycomb panel: light as a feather, indestructible!

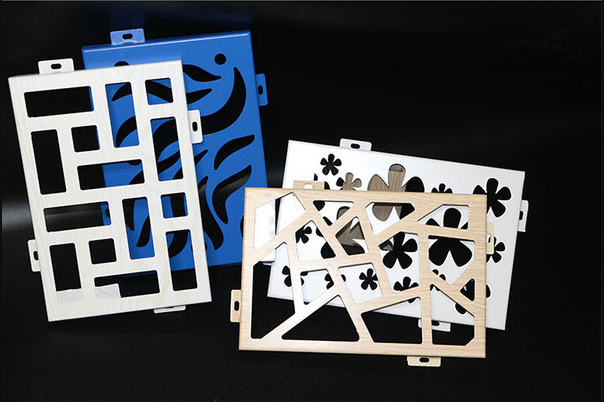

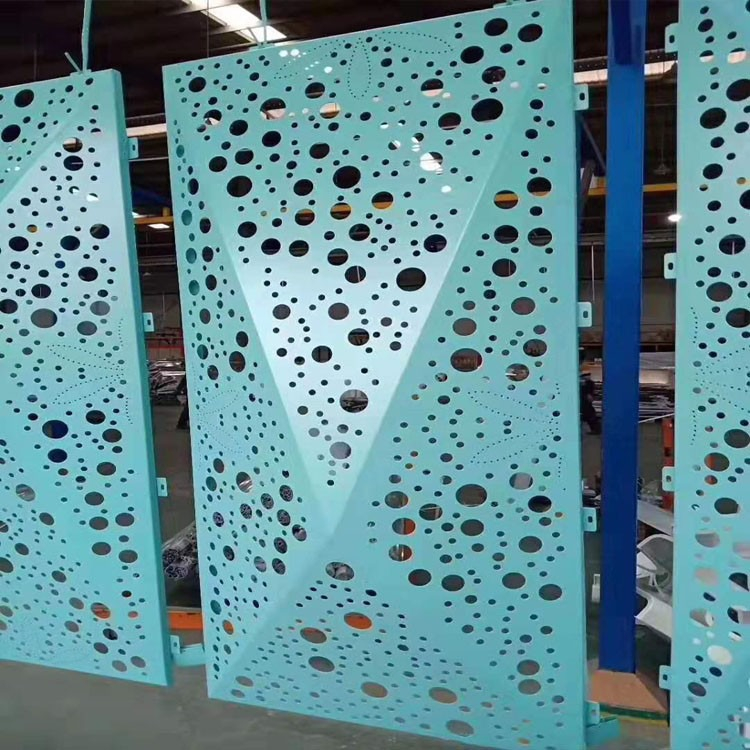

- Aluminum veneer customization, creating a new choice for personalized space!

- Aluminum veneer: creating a simple and modern architectural appearance

Industry dynamics

- Aluminum curtain wall: the new darling of modern architecture, revealing its charm

- Research on the Sound Insulation Performance of Aluminum Single Panel

- The secret behind aluminum ceiling: the perfect fusion of lightness and aesthetics

- Aluminum ceiling: a fashionable choice in modern architecture

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

Frequently asked questions

- Can aluminum veneer achieve customized design?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Is the surface treatment of aluminum veneer durable?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Has the production process of aluminum veneer reduced energy consumption?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret power behind lightness

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 10, 2025 23:54:42

- Click:0

Friends, today let's talk about a magical material - honeycomb aluminum plate. Does this name sound a bit fancy? Don't worry, listen to me slowly.

Honeycomb aluminum plate, as the name suggests, is composed of many small units like a honeycomb. These small units are like small "boxes" filled with aluminum. It sounds simple, but its role is enormous.

We need to talk about its lightness. Honeycomb aluminum plate is lightweight and has high strength, which is not bragging. You may think that aluminum is a heavy metal, but its honeycomb structure makes it lightweight. Don't believe me? Think about airplanes, many of their bodies are made of honeycomb aluminum panels. This not only reduces weight but also improves safety.

Let's talk about its application again. Honeycomb aluminum plates are widely used in aviation, aerospace, construction, electronics and other fields. Some of the planes you have flown on may be made of honeycomb aluminum panels. Also, those high-tech electronic products, such as smartphones and computers, may also use honeycomb aluminum panels for their heat dissipation modules.

How is honeycomb aluminum plate made lightweight and sturdy? We have to talk about its structure. The honeycomb structure is like a "skeleton" that supports the entire board. This structure can effectively disperse pressure and prevent the honeycomb aluminum plate from deforming when subjected to pressure. This structure can also increase the specific strength of the material, which is the ratio of its strength to its weight.

Speaking of which, I remember a story. Once, I saw workers at a construction site building a booth using honeycomb aluminum panels. I thought to myself, can this honeycomb aluminum plate withstand so many people with such light weight? As a result, the workers not only easily built the booth, but also jumped on it for several times. The booth is still as stable as Mount Tai. This makes me look at honeycomb aluminum panels with new eyes.

Honeycomb aluminum panels also have their shortcomings. Its cost is relatively high. After all, with such high technological content, the price is naturally not cheap. The processing difficulty is relatively high. The manufacturing process of honeycomb aluminum plate requires precise craftsmanship, which places high demands on equipment and technology.

However, these do not hinder the widespread application of honeycomb aluminum plates in various fields. In my opinion, honeycomb aluminum panels are like a 'wizard', perfectly combining lightness and sturdiness, bringing infinite possibilities to our lives.

What are the other magical aspects of honeycomb aluminum panels? Let's explore together!

The heat dissipation performance of honeycomb aluminum plate is very good. Due to its structural characteristics, honeycomb aluminum plates can effectively absorb and dissipate heat. This gives honeycomb aluminum panels a unique advantage in heat dissipation for electronic products. Imagine if your phone and computer could both use honeycomb aluminum panels, would that be enough to say goodbye to the problem of "high temperature"?

The corrosion resistance of honeycomb aluminum plate is also excellent. Honeycomb aluminum plates can maintain good performance in harsh environments such as humidity, acidity, and alkalinity. This makes it widely used in many outdoor, marine and other environments.

Let's talk about the environmental performance of honeycomb aluminum sheet. Honeycomb aluminum panels can be recycled and will not cause pollution to the environment. In the manufacturing process, the production process of honeycomb aluminum plate is also relatively environmentally friendly.

There are many applications of honeycomb aluminum panels, such as in solar panels, automotive lightweighting, high-speed rail, and other fields. It can be said that honeycomb aluminum sheet is gradually becoming a "business card" of China's manufacturing industry.

Honeycomb aluminum plate is a magical material that brings convenience to our lives with its advantages of lightweight, durability, and environmental friendliness. Perhaps in the near future, honeycomb aluminum panels will bring us even more surprises. Let's look forward to it together!

What I want to say is that the development of technology cannot be separated from innovation. It is these innovations that make our lives better. Like honeycomb aluminum panels, it perfectly combines lightness and sturdiness, bringing infinite possibilities to our lives. And we also need to constantly learn and innovate, contributing our own strength to the scientific and technological cause of our country. Come on, friends!

Customer service QQ

Customer service QQ