Industry information

Company News

- Aluminum veneer: lightweight building material, the new favorite of modern home furnishings

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer, the "silver elf" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- The secret of aluminum honeycomb panel: the technological power behind its lightweight design

Industry dynamics

- Aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum curtain wall, the fashionable "coat" of modern architecture

- The mysterious charm of honeycomb aluminum plate: the perfect fusion of lightness and sturdiness

- Honeycomb aluminum plate: a new darling of lightweight and high-strength modern building materials

- Aluminum veneer, your new darling of modern architecture!

Frequently asked questions

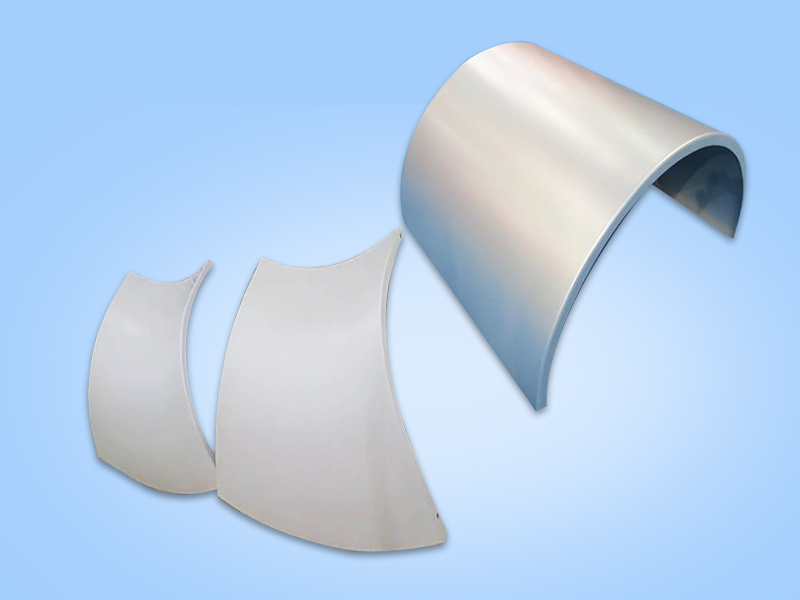

- Can aluminum veneer be used in the design of building arch bridges?

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How does the plasticity of aluminum veneer affect building comfort?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the compressive performance of punched aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 1, 2025 10:36:48

- Click:0

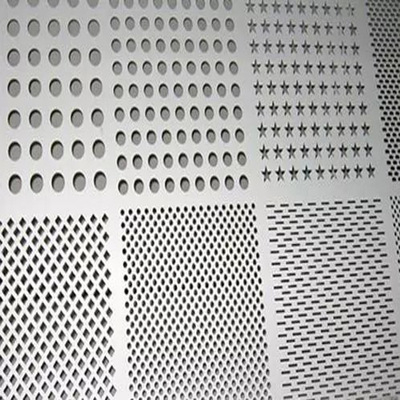

punchingAluminum veneerAs a material widely used in fields such as architectural decoration, billboards, curtain walls, etc., its compressive performance is also an important aspect. The compressive performance of punched aluminum veneer will be introduced from the following aspects.

1. Compressive strength of punched aluminum veneer

The compressive strength of punched aluminum veneer refers to the maximum pressure that the material can withstand when subjected to pressure. Generally speaking, the higher the compressive strength of a material, the better its compressive performance.

In punched aluminum veneer, commonly used metal materials include aluminum alloy and copper alloy. These materials have relatively high compressive strength, therefore their compressive performance is also good. However, due to the presence of a certain air layer on the surface of punched aluminum veneer, its actual compressive strength may be affected to some extent.

1. Tensile strength of punched aluminum veneer

The tensile strength of punched aluminum veneer refers to the maximum tensile force that the material can withstand when subjected to tension. Generally speaking, the higher the tensile strength of a material, the better its tensile performance.

In punched aluminum veneer, commonly used metal materials include aluminum alloy and copper alloy. These materials have relatively high tensile strength, so their tensile performance is also good. However, due to the presence of a certain air layer on the surface of punched aluminum veneer, its actual tensile strength may be affected to some extent.

1. How to improve the compressive performance of punched aluminum veneer

In order to improve the compressive performance of punched aluminum veneer, the following measures can be taken:

(1) Increasing the thickness of the material: Increasing the thickness of the material can improve its compressive performance. However, this will also increase costs and weight.

(2) Adopting better surface treatment methods: Adopting better surface treatment methods can improve the compressive performance of punched aluminum veneer. For example, fluorocarbon spraying can form a fluorocarbon film with good weather resistance and corrosion resistance on the surface of punched aluminum veneer, thereby improving its compressive performance.

(3) Increasing the number and position of reinforcement bars: Adding appropriate reinforcement bars to punched aluminum veneer can enhance its compressive performance. The quantity and position of reinforcement bars should be designed and adjusted according to specific circumstances.

The compressive performance of punched aluminum veneer is one of the important guarantees for its application effect and user experience. By optimizing material composition, adopting better surface treatment methods, and increasing the number and position of reinforcement bars, the compressive performance of punched aluminum veneer can be improved to meet the needs of different occasions.

Customer service QQ

Customer service QQ