Industry information

Company News

- The 'fresh little expert' in the aluminum ceiling industry: a new proposition for creating fashionable spaces

- Aluminum veneer: a low-key luxury choice in modern architecture

- Honeycomb aluminum plate: the secret behind lightweight structure

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer: the fashionable outerwear of modern architecture

- The aluminum veneer on the exterior wall created by roller coating technology makes the building more durable and beautiful

- The secret of aluminum honeycomb panel: the perfect combination of lightweight and sturdy

- Customize aluminum veneer to create personalized space art

- Customized aluminum veneer adds artistic flair to buildings

Frequently asked questions

- How can aluminum veneer improve the appearance of buildings?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- Has the production process of aluminum veneer reduced energy consumption?

- How does the service life of aluminum veneer compare to other exterior wall materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The secret of aluminum honeycomb panel: the technological power behind its lightweight design

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 12, 2025 11:34:20

- Click:0

Dear readers, today we will talk about a seemingly ordinary material that is actually full of technological sense - aluminum honeycomb panel. You may often see its presence at construction sites, car shows, or high-end furniture stores, but do you know the story behind it? Let me take you to explore the truth.

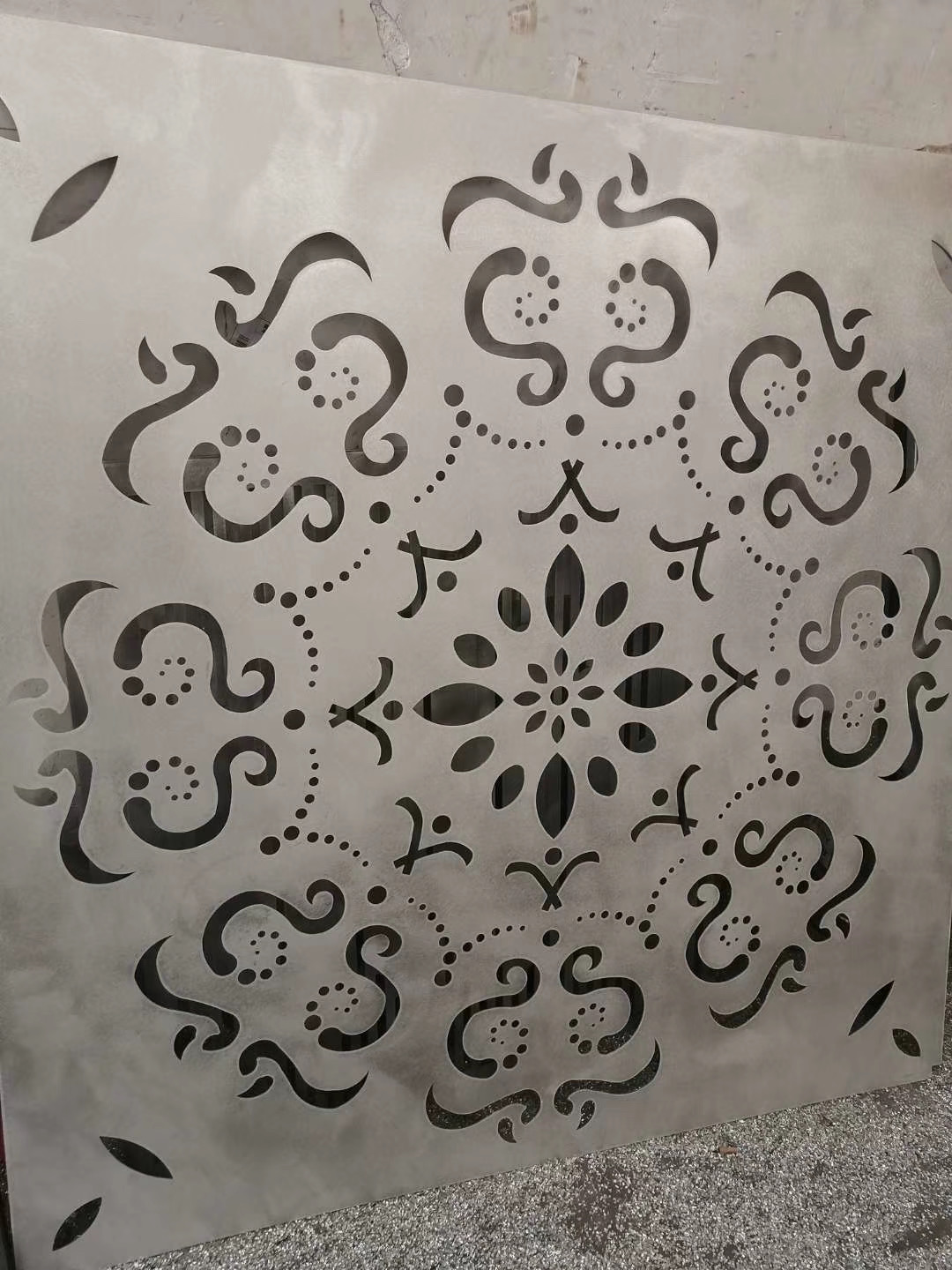

Let's talk about the name aluminum honeycomb panel. Honeycomb? Yes, you heard it right. The inspiration for this material comes from the honeycomb structure of bees. The honeycomb structure is lightweight, sturdy, and has excellent sound and heat insulation performance. Anthropologists and engineers were inspired by this and invented aluminum honeycomb panels.

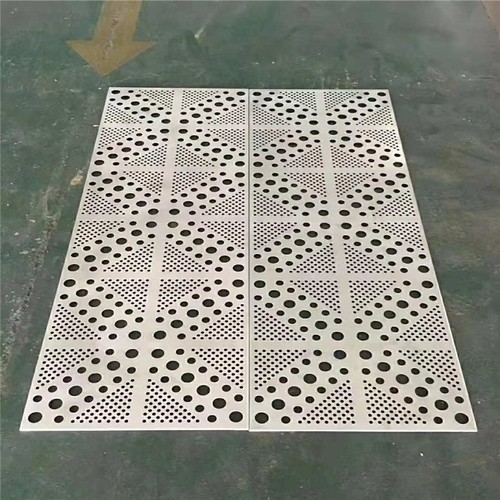

Aluminum honeycomb panels are mainly composed of aluminum honeycomb cores and double-sided aluminum plates. The honeycomb core is the key, it is like a honeycomb, composed of countless hexagonal small units. These small units are hollow and filled with air. In this way, aluminum honeycomb panels have high strength and stability, while being lightweight.

You may ask, how can such light materials support such a heavy building? This is thanks to the strength of the aluminum honeycomb panel. The structure of the honeycomb core enables aluminum honeycomb panels to evenly distribute force across the entire surface when subjected to pressure. This is like a spring that can withstand great pressure while maintaining its shape.

In addition to its high strength, aluminum honeycomb panels also have excellent sound and heat insulation properties. This is because the air layer in the honeycomb core can effectively block the transfer of sound and heat. In some occasions that require sound and heat insulation, such as recording studios, conference rooms, high-end residences, etc., aluminum honeycomb panels come in handy.

The application of aluminum honeycomb panels goes far beyond this. In the field of automobile manufacturing, aluminum honeycomb panels are widely used in body, chassis and other parts, which not only reduces the weight of the car but also improves safety. In the aerospace field, aluminum honeycomb panels are an indispensable material, providing lightweight and sturdy structures for aircraft, rockets, and other applications.

How is aluminum honeycomb panel made? Cut the aluminum plate into the required size and then process it into a honeycomb core. The production process of honeycomb cores is quite complex, requiring folding aluminum plates into small hexagonal units and filling them with air. By bonding the processed honeycomb core and aluminum plate together, an aluminum honeycomb panel is obtained.

Although aluminum honeycomb panels have many advantages, they also have some disadvantages. It is relatively expensive and difficult to process. During the use of aluminum honeycomb panels, attention should be paid to moisture and corrosion prevention issues.

Speaking of which, I remembered a story. Once, I saw a sofa made of aluminum honeycomb panels at a high-end furniture store. This sofa has a unique design with smooth lines, giving people a feeling of lightness and fashion. I couldn't help but sit up and experience it, and I didn't expect it to be very comfortable. At this point, the salesperson told me that this sofa uses aluminum honeycomb panels as filling material, which not only ensures comfort but also has good support.

This story gave me a deeper understanding of aluminum honeycomb panels. It is not just a material, but also a technology and an art. In this fast-paced era, aluminum honeycomb panels bring endless surprises to our lives with their unique charm.

Aluminum honeycomb panel is a material with high technological content. It is lightweight, sturdy, soundproof, and heat-insulating, widely used in various fields. Although it has some shortcomings, the flaws do not overshadow its merits. I believe that with the continuous development of technology, aluminum honeycomb panels will unleash their magical power in more fields.

I have a question for everyone: Where do you use aluminum honeycomb panels around you? Welcome to leave a comment in the comment section to share your story. Let's explore this magical world of aluminum honeycomb panels together!

Customer service QQ

Customer service QQ