Industry information

Company News

- Aluminum veneer: a modern interpretation of architectural aesthetics

- The secret of honeycomb aluminum plate: innovative wisdom behind its lightweight design

- Customized aluminum veneer, creating a new trend of personalized space!

- Honeycomb aluminum plate: the innovative path of lightweight materials

- Aluminum curtain wall: the fashionable coat of modern architecture

Industry dynamics

- High temperature environment punching aluminum veneer

- Aluminum Veneer: Exploring the Charm of New Era Building Materials

- Seismic performance and safety evaluation of 2mm aluminum veneer

- Unlimited creativity and diverse styles - infinite possibilities for ceiling painted aluminum veneer

- Aluminum curtain wall: the fashionable coat of modern architecture

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How can aluminum veneer improve the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- Can aluminum veneer achieve customized design?

- Is the surface treatment of aluminum veneer durable?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret behind lightweight materials

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-20 07:07:03

- Click:0

Dear readers, today let's talk about a magical material - honeycomb aluminum plate. You may have heard of it, or you may have never paid attention to it. But don't underestimate it, this small guy can be very useful in many fields.

We need to talk about the appearance of honeycomb aluminum panels. Imagine a honeycomb, where each small cell is made of aluminum plate. This is what honeycomb aluminum sheet looks like. Do you think it's a bit unbelievable? How can such a thin piece support such a large weight? This is the magic of honeycomb aluminum sheet.

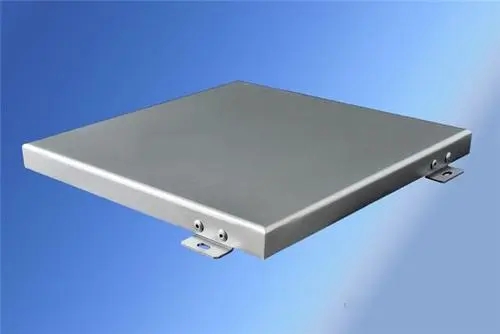

The characteristics of honeycomb aluminum plate are lightweight, sturdy, and corrosion-resistant. Its density is only one-third of steel, but it can withstand greater pressure than steel. Do you think it's a bit like magic? There are complex scientific principles behind this.

The lightweight of honeycomb aluminum plate is due to its unique structure. Honeycomb structure has excellent bending resistance and can effectively disperse pressure. This is like a honeycomb, where each small cell can bear a certain weight and together support the entire honeycomb. And honeycomb aluminum plate is the application of this structure to aluminum plate, making it both lightweight and sturdy.

The application range of honeycomb aluminum plate is very wide. In the aerospace field, it is used to manufacture structural components of aircraft, such as wings, fuselage, etc. Because honeycomb aluminum panels are lightweight and sturdy, they can reduce the weight of airplanes and improve fuel efficiency. Honeycomb aluminum panels are also widely used in the field of construction. Honeycomb aluminum panels can leverage their advantages in the roofs, walls, partitions, and other areas of high-rise buildings.

I remember once I visited a skyscraper under construction. The workers are using honeycomb aluminum panels to build the roof of the building. Looking at those thin aluminum plates, I couldn't help but ask a question: "Can such a thin aluminum plate really withstand such a lot of pressure?" The foreman smiled and said, "This honeycomb aluminum plate has undergone strict testing, it's lightweight and sturdy. Don't worry

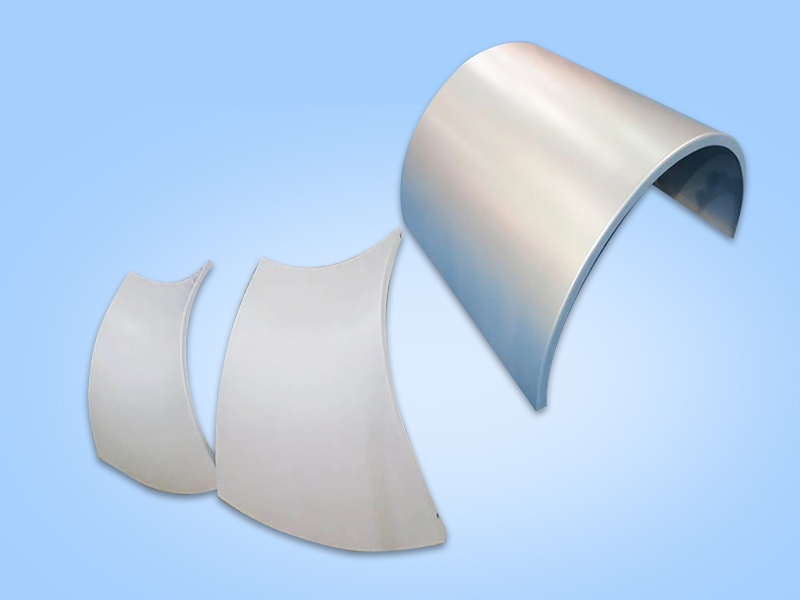

Honeycomb aluminum sheet also has a wide range of applications in the field of automotive manufacturing. Some high-end car models use honeycomb aluminum panels to manufacture the body. This not only reduces the weight of the vehicle, but also improves fuel efficiency. Honeycomb aluminum plates are also used in the manufacturing of transportation vehicles such as ships, trains, and airplanes.

The application of honeycomb aluminum plate is not limited to this. In the field of electronic products, it is used to manufacture heat sinks for devices such as mobile phones and computers. In the field of sports equipment, it is used to manufacture badminton rackets, tennis rackets, etc. Honeycomb aluminum panels have penetrated into every aspect of our lives.

What is the production process of honeycomb aluminum plate? Making honeycomb aluminum panels is not complicated. Cut the aluminum plate into the desired size and fold it into a honeycomb shape. This process requires precise craftsmanship and equipment. Surface treatment of honeycomb aluminum plate to enhance its corrosion resistance.

Honeycomb aluminum plates also have their drawbacks. Its cost is relatively high. The processing difficulty of honeycomb aluminum plate is relatively high, requiring professional equipment and technology. However, with the continuous development of technology, these problems are gradually being solved.

Honeycomb aluminum plate is a magical material. It is lightweight, sturdy, and corrosion-resistant, bringing us many conveniences. Perhaps in the near future, honeycomb aluminum panels will become an indispensable part of our lives. Let's look forward to this beautiful future together!

Customer service QQ

Customer service QQ