Industry information

Company News

- Aluminum veneer, the "fashionable coat" of modern architecture

- Aluminum honeycomb panel: the technological secret behind its lightweight design

- Honeycomb aluminum plate: the technological power behind lightness

- Aluminum Ceiling: The Light Luxury Choice in Modern Architecture

- Honeycomb aluminum plate: as light as a feather, as strong as a rock

Industry dynamics

- Analysis of Marketing Channels for Aluminum Veneer Manufacturers

- Aluminum Curtain Wall: The Silver Coat of Modern Architecture

- The aesthetic charm of aluminum veneer decoration on the exterior wall of the doorway

- Aluminum veneer customization, creating a new trend of personalized space

- Honeycomb aluminum plate: the secret journey behind lightness

Frequently asked questions

- How can aluminum veneer improve the appearance of buildings?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- What is the manufacturing process of aluminum veneer?

- Has the production process of aluminum veneer reduced energy consumption?

- Can aluminum veneer achieve customized design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The secret of honeycomb aluminum plate: the technological miracle behind its lightweight design

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 16, 2025 21:35:37

- Click:0

Hey guys, do you know? In our daily lives, there is a seemingly ordinary material that contains magical technology, which is honeycomb aluminum plate. Let me reveal to you the technological miracle behind this lightness!

Let's imagine, if given a lightweight, sturdy, and super insulating building material, what would you want to use it for? That's right, honeycomb aluminum plate is such a magical material. It is as light as a feather, yet it can excel in fields such as architecture, aviation, and automobiles.

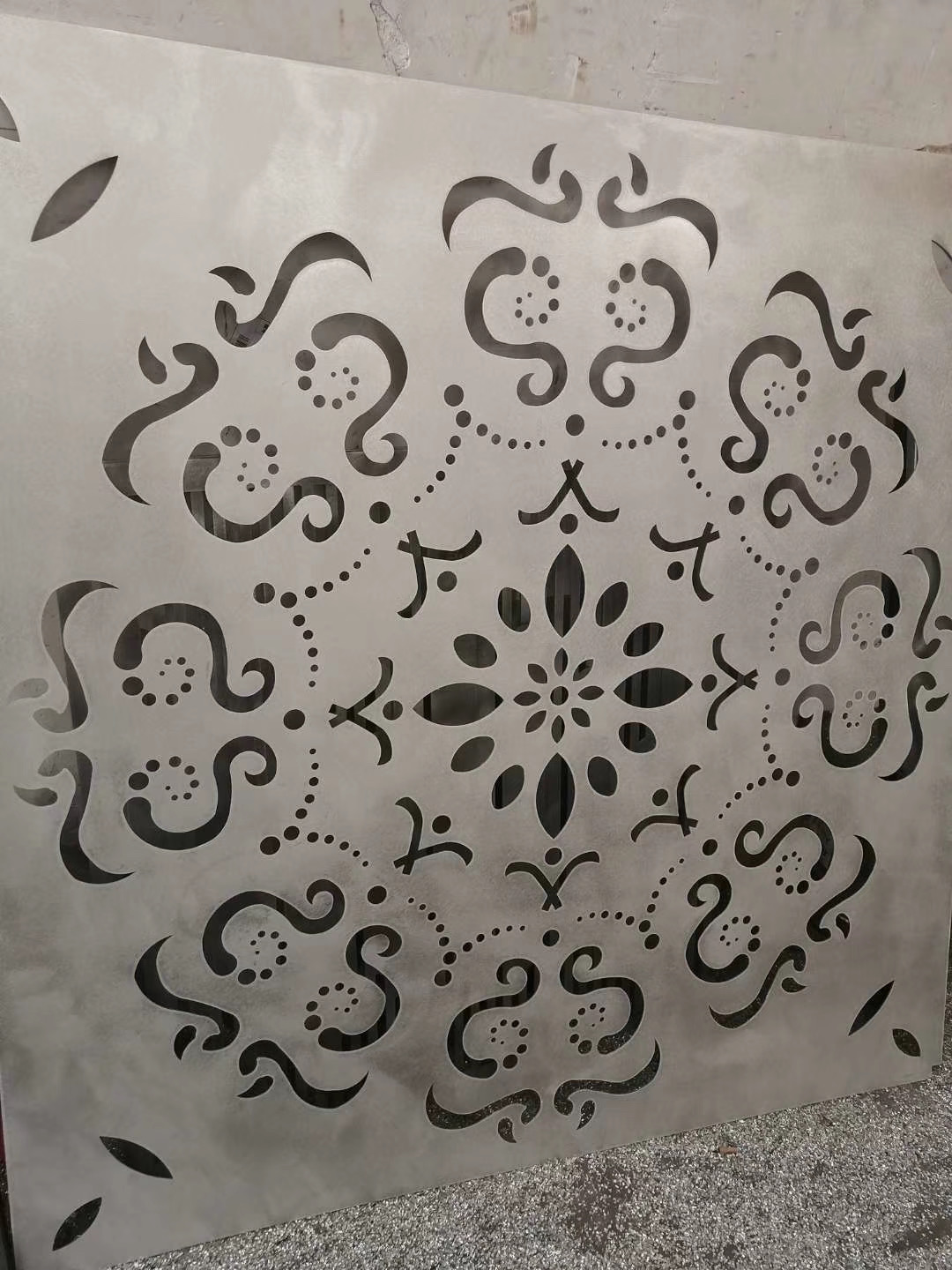

The secret to the lightness of honeycomb aluminum panels lies in their structure. It is composed of many hexagonal honeycomb cells, which are like small boxes tightly arranged together. This structure enables honeycomb aluminum panels to maintain lightweight while also possessing strong compressive strength. Imagine if the same weight of stones and honeycomb aluminum plates were stacked together, the honeycomb aluminum plates would be stacked higher, indicating how strong their compressive strength is!

How is honeycomb aluminum plate made both lightweight and sturdy? This is also thanks to its manufacturing process. When manufacturing honeycomb aluminum plates, the first step is to cut the aluminum plates into the required size, and then heat them to a certain temperature to make them soft. Press the soft aluminum plate into a honeycomb shape, and then go through processes such as cooling and curing to finally produce a honeycomb aluminum plate.

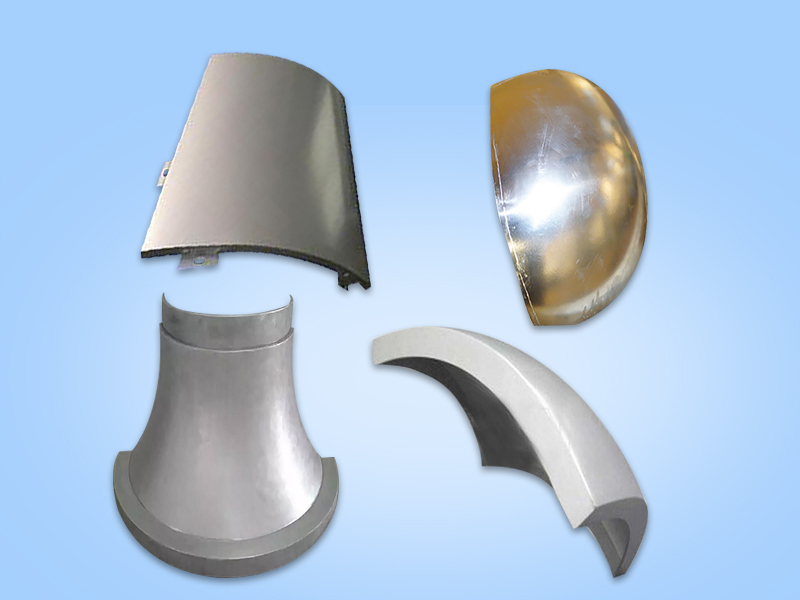

The unique structure of honeycomb aluminum plate not only makes it lightweight, but also brings many unexpected benefits. In the field of architecture, honeycomb aluminum panels can be used as partition walls, ceilings, roof panels, etc. It can reduce the weight of buildings and improve their thermal insulation performance. In the aviation industry, honeycomb aluminum panels can be used to manufacture aircraft skins, wing beams, and other components, improving the aircraft's load-bearing capacity and fuel efficiency. In the automotive industry, honeycomb aluminum panels can be used to manufacture body, chassis, and other components, reducing the weight of the car and improving fuel economy.

The application of honeycomb aluminum sheet is far more than that. In the field of electronic devices, honeycomb aluminum plates can be used as heat sinks to help dissipate heat from devices; In the field of sports equipment, honeycomb aluminum plates can be used to manufacture rackets, helmets, etc., improving the performance and durability of the equipment.

However, honeycomb aluminum panels also have their shortcomings. Its price is relatively high and not suitable for large-scale popularization. In terms of recycling, the difficulty of recycling honeycomb aluminum plates is relatively high, which brings certain pressure to environmental protection.

What will the future hold for honeycomb aluminum panels? I think that with the continuous development of technology, the manufacturing process of honeycomb aluminum panels will become more mature and the cost will be further reduced. With the increasing awareness of environmental protection, the recycling technology of honeycomb aluminum panels will also be improved. In this way, the application range of honeycomb aluminum panels will be more extensive, becoming an indispensable part of our lives.

Returning to my initial question, if given a lightweight, sturdy, and super insulating building material, what would you want to use it for? This is not a multiple-choice question, but it makes us pay more attention to these seemingly ordinary items around us that contain magical technology. Just like honeycomb aluminum panels, they silently bring convenience to our lives.

Honeycomb aluminum plate is a magical material that is lightweight, sturdy, and has good insulation performance, widely used in various fields. Although it still has its shortcomings, with the advancement of technology, I believe its future will be even better. Let's look forward to the technological miracle behind this lightweight and continue to change our lives!

Customer service QQ

Customer service QQ