Industry information

Company News

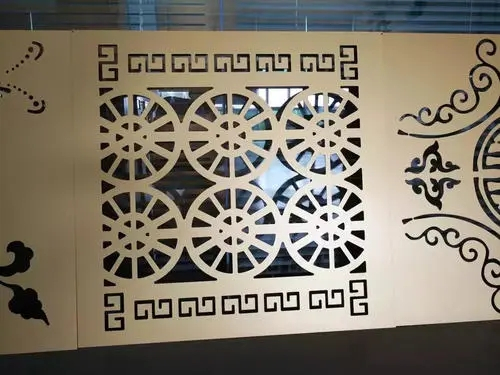

- Aluminum veneer customization, creating personalized spatial aesthetics

- Aluminum veneer customization: personalized space, separated by one board

- Aluminum honeycomb panel: the technological secret behind its lightweight design

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: not only a building material, but also a paintbrush for architectural art

Industry dynamics

- The secret of aluminum honeycomb panel: lightweight and high-strength, the new favorite of future architecture

- Aluminum Ceiling: An Invisible Artwork in Modern Architecture

- Aluminum veneer: The secret story behind its lightweight design

- Aluminum veneer, the 'hidden hero' of modern architecture

- Customize aluminum veneer to create personalized space and new fashion!

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Can aluminum veneer be used in the design of building arch bridges?

- Can aluminum veneer achieve customized design?

- How can aluminum veneer improve the appearance of buildings?

- What is the manufacturing process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

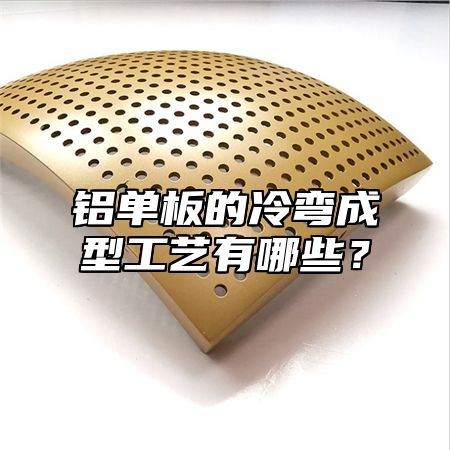

What are the cold bending forming processes for aluminum veneer?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 11:35:45

- Click:0

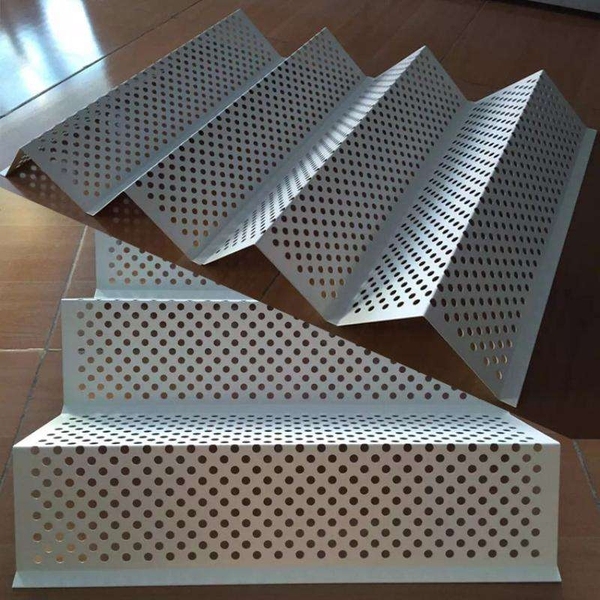

Aluminum veneerThe cold bending process is a method of processing aluminum into the desired shape, which has the advantages of reducing material waste, improving production efficiency, and reducing costs. Here are some common cold bending processes for aluminum veneer:

1. Manual bending

Manual bending is a traditional cold bending process for aluminum veneers, suitable for smaller sizes of aluminum veneers. When performing manual bending, professional bending machines and tools are required to complete it. Due to the manual operation required for manual bending, the production efficiency is relatively low, but it can ensure product quality and accuracy.

1. Mechanical bending

Mechanical bending is a common cold bending process for aluminum veneers, suitable for larger sizes of aluminum veneers. When performing mechanical bending, professional bending machines and equipment are required to complete it. The advantages of mechanical bending are high production efficiency and fast speed, but it requires high technical level and experience from workers.

1. Hot bending

Hot bending is a new type of cold bending process for aluminum veneer, suitable for more complex shapes of aluminum veneer. When performing hot bending, it is necessary to heat the aluminum material to a certain temperature before bending. The advantage of hot bending is that it can achieve the production of aluminum veneer with complex shapes, but it requires high equipment and technical requirements.

1. Hydraulic bending

Hydraulic bending is an advanced cold bending process for aluminum veneer, suitable for large-scale production of aluminum veneer. When performing hydraulic bending, professional hydraulic machines and equipment are required to complete it. The advantages of hydraulic bending are high production efficiency, fast speed, and precise control of pressure and deformation of aluminum materials.

There are multiple options for the cold bending process of aluminum veneer, each with its own characteristics and applicable scope. When cold bending aluminum veneer, it is necessary to choose the appropriate process according to the actual situation and pay attention to the influence of various factors to ensure product quality and safety. It is recommended to choose a professional construction team to carry out the cold bending forming work of aluminum veneer to ensure construction quality and effectiveness.

- previous page:UV resistance and protection of aluminum veneer

- Next page:Is the strength of aluminum veneer sufficient?

Customer service QQ

Customer service QQ