Industry information

Company News

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Honeycomb aluminum plate: a lightweight choice, the new favorite of modern architecture

- The Light of Aluminum Curtain: The New Favorite of Modern Architecture

- Aluminum ceiling, hidden aesthetics of new home fashion

- Aluminum Ceiling: Creating a New Style of Modern Home Furnishings

Industry dynamics

- The magical charm of honeycomb aluminum plate: a lightweight and strong secret weapon

- The shaping of architectural image by curtain wall aluminum veneer

- Can aluminum veneer replace traditional building materials?

- Aluminum Curtain Feast: A New Chapter in the Aesthetics of Modern Architecture

- Aluminum veneer: the beauty of architecture, starting from details

Frequently asked questions

- How does the plasticity of aluminum veneer affect building comfort?

- What is the manufacturing process of aluminum veneer?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the impact of the thickness of aluminum veneer on its performance?

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-02-24 05:02:20

- Click:0

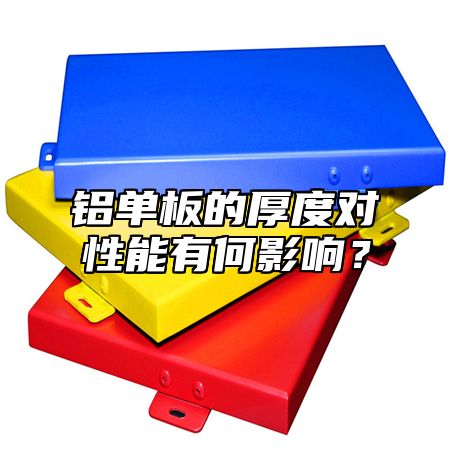

Aluminum veneerIt is a building material widely used in fields such as architecture, billboards, curtain walls, etc. Its thickness is one of the important factors affecting its performance. The following will provide a detailed introduction to the influence of aluminum veneer thickness on performance and its selection method.

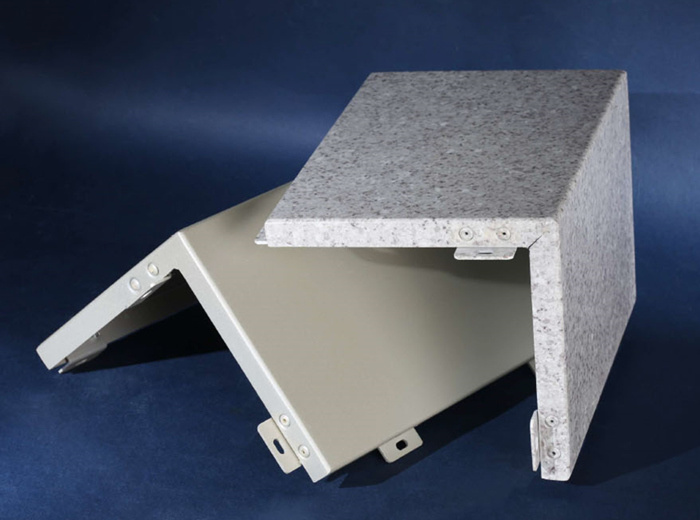

The thickness of aluminum veneer is related to its strength and stiffness

The thickness of aluminum veneer directly affects its strength and stiffness. Generally speaking, the thicker the aluminum veneer, the higher its strength and stiffness. This is because the increase in thickness of aluminum veneer will lead to an increase in its cross-sectional area, resulting in a corresponding increase in the pressure and bending force it can withstand. In situations where significant pressure or bending force is required, thicker aluminum veneers should be selected to enhance their strength and stiffness.

The thickness of aluminum veneer is related to its corrosion resistance

The thickness of aluminum veneer also affects its corrosion resistance. Generally speaking, the thinner the aluminum veneer, the more susceptible its surface is to oxidation and corrosion. In situations where long-term exposure to outdoor environments is required, thicker aluminum veneers should be selected to improve their corrosion resistance. When choosing aluminum veneer, attention should also be paid to its surface treatment method, such as anodizing treatment, to improve its corrosion resistance.

The thickness of aluminum veneer is related to its thermal insulation performance

The thickness of aluminum veneer also affects its thermal insulation performance. Generally speaking, the thinner the aluminum veneer, the higher its thermal conductivity, resulting in poorer insulation performance. In situations where insulation treatment is required, thicker aluminum veneers should be selected to improve their insulation performance. When choosing aluminum veneer, attention should also be paid to its surface treatment method, such as fluorocarbon coating treatment, to improve its thermal insulation performance.

The thickness of aluminum veneer has a significant impact on its performance. Consumers should choose aluminum veneer according to their actual usage needs to ensure that its performance meets the requirements. Attention should also be paid to the characteristics of materials and structural limitations during design and installation to ensure that the construction effect meets the requirements.

Customer service QQ

Customer service QQ