Industry information

Company News

- Aluminum veneer: a fashionable choice in modern architecture

- Aluminum ceiling, hidden industrial beauty

- Aluminum Curtain Wall: A Fashionable Choice in Modern Architecture

- Aluminum veneer: the "green clothing" of modern architecture

- Honeycomb aluminum plate: a lightweight and strong secret weapon

Industry dynamics

- The counterattack of honeycomb aluminum plate: the secret behind its lightness

- Customized aluminum veneer, creating personalized space and new fashion

- Diversified aluminum veneer shapes

- The charm of aluminum honeycomb panels: a perfect combination of lightness and strength

- Aluminum ceiling trend: the beauty of lightness, the new favorite of home furnishings

Frequently asked questions

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Can aluminum veneer be used in the design of building arch bridges?

- What is the manufacturing process of aluminum veneer?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Understand the production process and quality assurance of special-shaped perforated aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-16 14:45:07

- Click:0

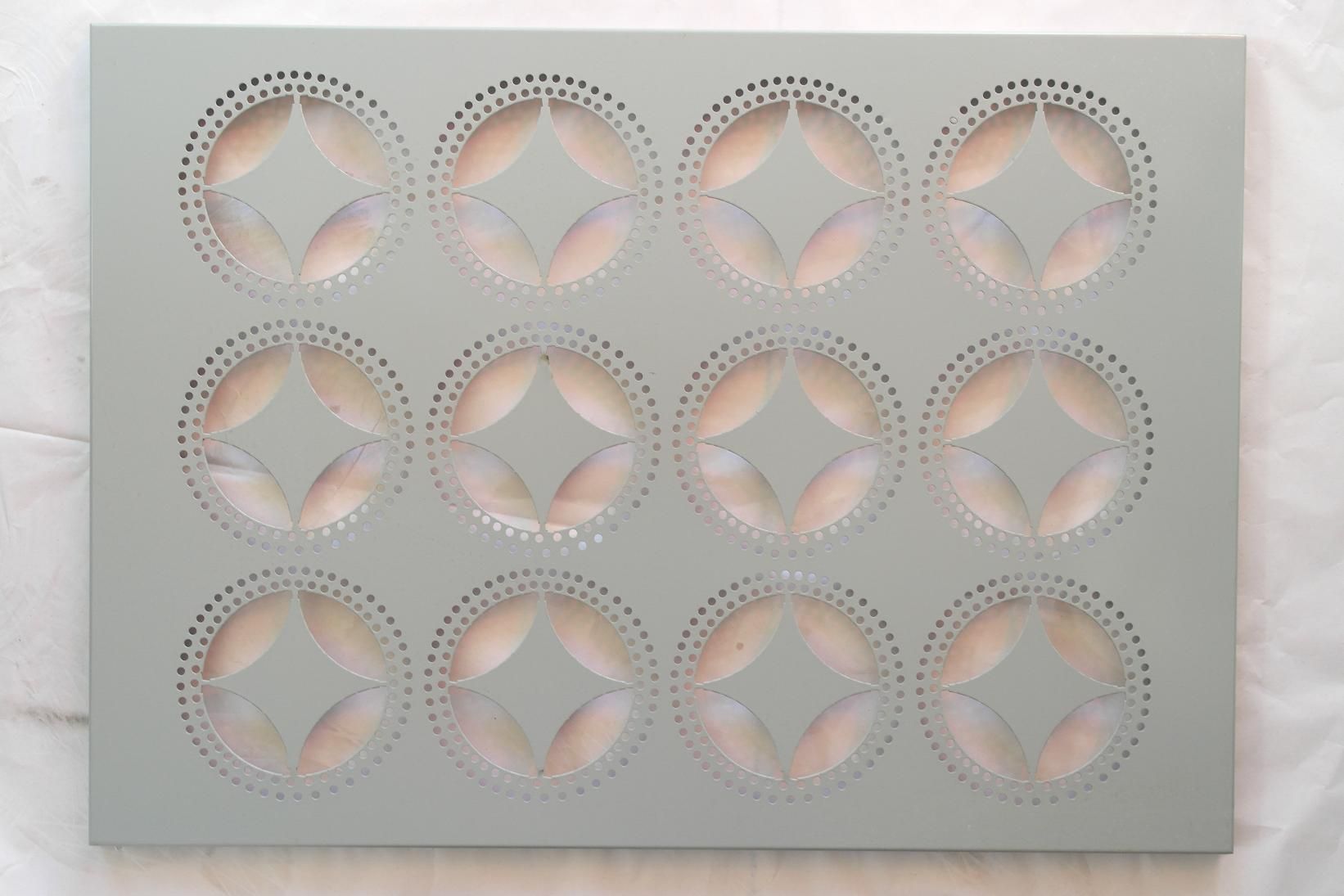

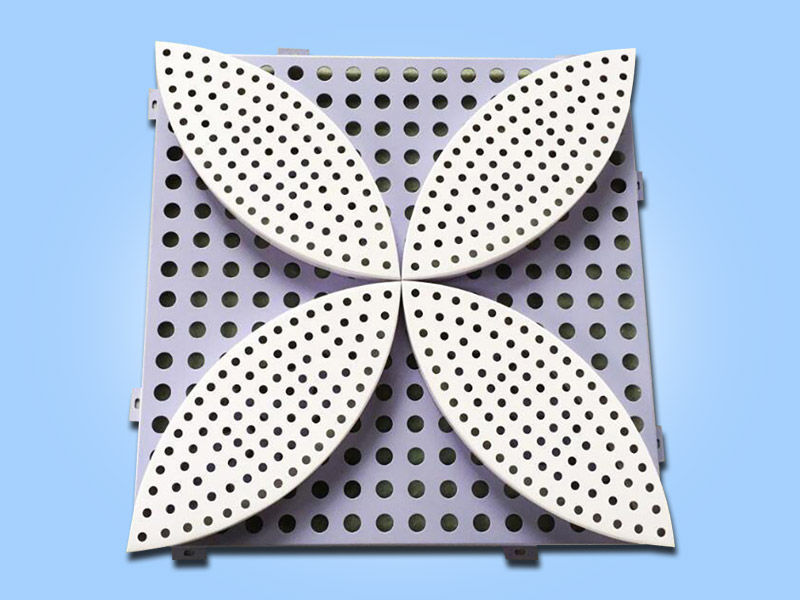

Irregular perforationAluminum veneerIt is a high-end decorative material, and its production process and quality assurance are of great significance for the quality and market competitiveness of the product. Here are some contents about understanding the production process and quality assurance of special-shaped perforated aluminum veneer.

1、 Production process

1. Raw materials: The main raw material for special-shaped perforated aluminum veneer is aluminum alloy, which needs to undergo strict screening and testing to ensure that the quality and performance of the material meet the requirements.

2. Cutting and processing: Cutting and processing aluminum alloy raw materials to produce aluminum veneers of various shapes and sizes. During the cutting process, attention should be paid to avoiding problems such as cracks and defects.

3. Punching processing: Punching the aluminum veneer to create a perforated effect, increasing its aesthetics and breathability. Attention should be paid to avoiding deformation and damage during the drilling process.

4. Surface treatment: Anodizing treatment is applied to aluminum veneer to increase its corrosion resistance and aesthetics. At the same time, surface treatments such as polishing and spraying are also required to improve the appearance quality and performance of the product.

2、 Quality assurance

1. Quality control: It is necessary to strictly control the quality of each link in the production process, including the selection of raw materials, control of processing, quality of surface treatment, etc., to ensure the qualification rate and stability of the product.

2. Testing and certification: Irregular perforated aluminum veneer needs to pass relevant testing and certification, such as ISO9001 quality management system certification, CE certification, etc., to prove that its quality and performance meet international standards and customer requirements.

3. After sales service: For the special-shaped perforated aluminum veneer that has already been sold, it is necessary to provide comprehensive after-sales service, including solving product quality problems, providing guidance on use, and maintenance, in order to improve customer satisfaction and loyalty.

3、 Summary

Understanding the manufacturing process and quality assurance of special-shaped perforated aluminum veneer is crucial for selecting and using this product. Only through strict production control and quality inspection can the quality and performance of the product be guaranteed to meet the requirements. Comprehensive after-sales service is also one of the important means to improve customer satisfaction and corporate competitiveness. When purchasing and using special-shaped perforated aluminum veneers, it is necessary to choose reputable and powerful enterprises, and pay attention to product quality and service experience.

Customer service QQ

Customer service QQ