Industry information

Company News

- Aluminum ceiling: the beauty of fashion hidden in the ordinary

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum Ceiling: The Art and Practical Choice of Modern Space

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer: bringing unique texture and luster to buildings

- Aluminum veneer new trend: a fashionable choice for light luxury buildings

- Aluminum honeycomb panel: the invisible hero of modern architecture

- Aluminum ceiling, a fashionable choice for creating modern spaces!

- The secret of aluminum honeycomb panel: the perfect combination of lightness and sturdiness

Frequently asked questions

- Can aluminum veneer be used in the design of building arch bridges?

- Is the surface treatment of aluminum veneer durable?

- How does the plasticity of aluminum veneer affect building comfort?

- Can aluminum veneer achieve customized design?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

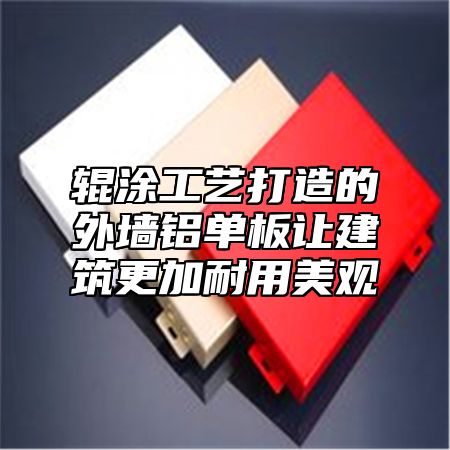

The aluminum veneer on the exterior wall created by roller coating technology makes the building more durable and beautiful

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-11 08:15:11

- Click:0

Roller coating technology is an excellent surface treatment process that can makeAluminum veneerThe surface is smoother, more uniform, and more aesthetically pleasing, while also improving its durability and anti-corrosion performance. In the field of architecture, roller coating technology is widely used in the manufacturing of exterior aluminum veneer, making buildings more durable and beautiful.

1、 Advantages of Roll Coating Process

Compared to traditional spraying processes, roller coating has the following advantages:

1. Higher coating quality: The roll coating process can distribute the coating more evenly on the surface of the aluminum veneer, thereby improving the quality and appearance of the coating.

2. Stronger durability: Due to the roll coating process, thicker coatings can be formed, which improves the durability of aluminum veneer and better resists the influence of external environment.

3. Better anti-corrosion performance: The roller coating process can form a stronger coating, which can effectively prevent aluminum veneer from being damaged by oxidation, corrosion, and other factors.

2、 Application of Roll Coating Process

In the field of architecture, roller coating technology is widely used in the manufacturing of exterior aluminum veneer. Compared with traditional spraying techniques, roller coating technology can better meet the requirements of building exterior walls, making the building more durable and beautiful. Specifically, the roller coating process has advantages in the following aspects:

1. Better appearance effect: Due to the roller coating process, a more uniform and delicate coating can be formed, resulting in a better appearance effect of aluminum veneer, brighter colors, and higher glossiness.

2. Stronger durability: Due to the roll coating process, thicker coatings can be formed, which improves the durability of aluminum veneer and better resists the influence of external environment.

3. Better anti-corrosion performance: The roller coating process can form a stronger coating, which can effectively prevent aluminum veneer from being damaged by oxidation, corrosion, and other factors.

3、 Conclusion

Roller coating technology is an excellent surface treatment process that can make the surface of aluminum veneer smoother, more uniform, and more beautiful, while also improving its durability and anti-corrosion performance. In the field of architecture, roller coating technology is widely used in the manufacturing of exterior aluminum veneer, making buildings more durable and beautiful. In the future, with the development of technology and continuous improvement of production processes, it is believed that roll coating technology will be applied in more fields.

Customer service QQ

Customer service QQ