Industry information

Company News

- Aluminum ceiling: low-key luxury in modern architecture

- Aluminum veneer: not just sheet metal, but also the soul of modern architecture

- Honeycomb aluminum plate: Unveiling the secrets behind lightness

- The secret of aluminum honeycomb panel: the hard power behind its lightness

- The Beauty of Aluminum Ceiling: The Perfect Fusion of Lightness and Texture

Industry dynamics

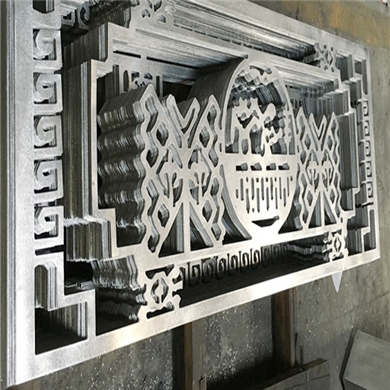

- Advantages and application areas of carved aluminum veneer on door heads

- Honeycomb aluminum plate: the technological secret behind its lightweight design

- Aluminum curtain wall: the fashionable coat of urban architecture

- Aluminum curtain wall: the beauty of architecture, the light of innovation

- Aluminum curtain wall: not only a facade project, but also a tool for architectural innovation!

Frequently asked questions

- Can aluminum veneer be used in the design of building arch bridges?

- Is the surface treatment of aluminum veneer durable?

- What is the manufacturing process of aluminum veneer?

- How does the plasticity of aluminum veneer affect building comfort?

- How can aluminum veneer improve the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the appearance effect of 3mm aluminum veneer under punching process

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 24, 2025 18:44:21

- Click:0

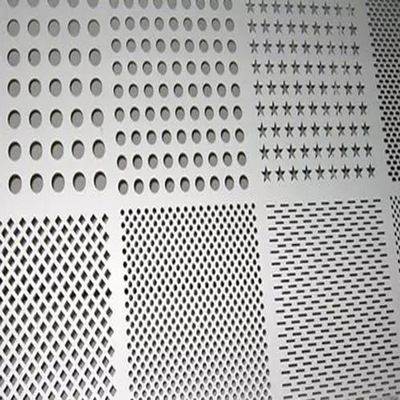

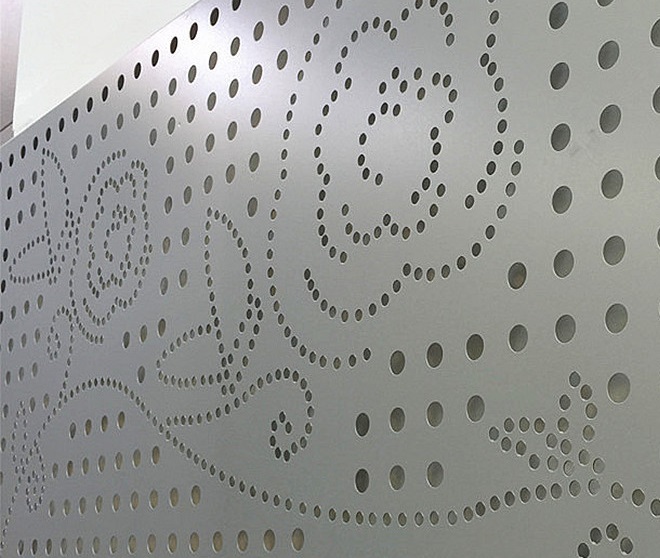

Punching process is a common techniqueAluminum veneerThe processing method involves punching holes of different sizes and shapes on the surface of aluminum veneer to achieve different decorative effects. The following will analyze the appearance effect of 3mm aluminum veneer under punching technology.

1、 Overall appearance effect

1. Uniformity

The overall appearance of 3mm aluminum veneer under punching process is relatively uniform, and the size and distribution of holes are relatively regular. This is because the punching equipment can precisely control the position and force of the punch, ensuring consistency in the distribution and size of the holes.

2. Aesthetics

Under the punching process, 3mm aluminum veneer can achieve various decorative effects by adjusting parameters such as the number, size, and distribution of punches. For example, increasing the number and size of punch heads can enhance the visual impact and three-dimensional sense of aluminum veneer; Various decorative effects such as rain resistance, sound insulation, thermal insulation, and ventilation can also be achieved by adjusting the distribution of the punch heads.

2、 Local appearance effect

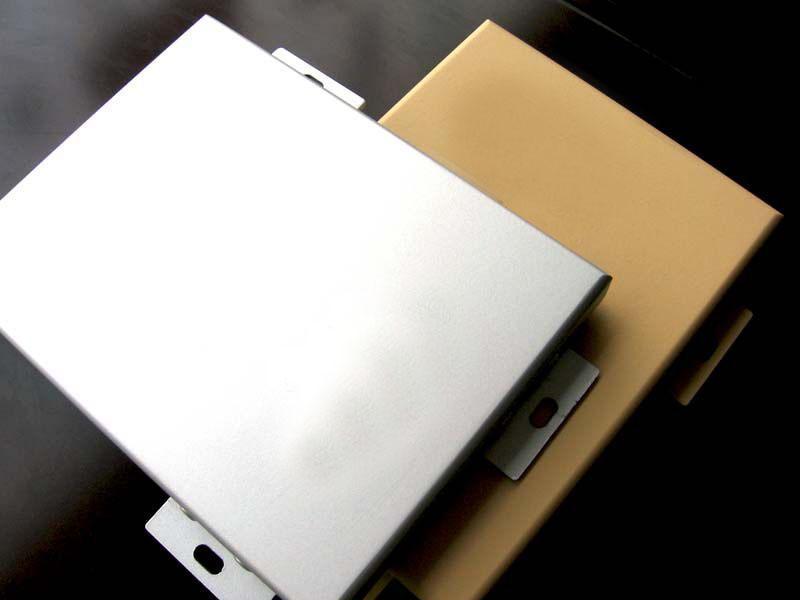

1. Edge treatment of holes

The edge treatment of 3mm aluminum veneer holes under punching process is one of the important factors affecting its appearance. Some high-end punching equipment can achieve finer edge processing of holes, such as rounded corners, chamfers, etc., thereby improving the overall aesthetics of aluminum veneer.

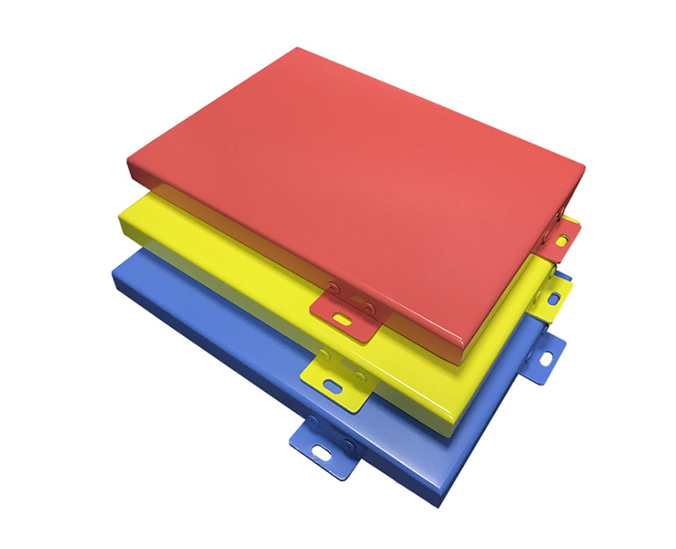

2. Color matching

In addition to edge treatment of holes, the color matching of 3mm aluminum veneer is also an important factor affecting its appearance. Some companies have started using colorful spraying technology to process 3mm aluminum veneer, which can be customized according to customer needs to meet different building structures and design requirements.

3、 Summary

Under the punching process, 3mm aluminum veneer has good uniformity and aesthetics, and various decorative effects can be achieved by adjusting parameters such as the number, size, and distribution of punches. Edge treatment and color matching of holes are also important factors affecting their appearance. In the future, with the continuous progress and innovation of technology, the punching process of 3mm aluminum veneer will become more mature and perfect, bringing more new ideas and solutions to the building decoration industry.

Customer service QQ

Customer service QQ