Industry information

Company News

- Aluminum curtain wall, the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum veneer: a low-key luxury choice in modern architecture

- Customized aluminum veneer: the art of creating personalized spaces

Industry dynamics

- Aluminum ceiling, creating a perfect space for fashion and practicality

- How economical is aluminum veneer in architectural exterior design?

- The secret of aluminum veneer: the story behind its lightness

- The charm of aluminum veneer, one board, one world

- Aluminum veneer customization: the art of creating personalized spaces

Frequently asked questions

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- How can aluminum veneer improve the appearance of buildings?

- Can aluminum veneer achieve customized design?

- What is the manufacturing process of aluminum veneer?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Electrophoretic process of 2.5mm aluminum veneer

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 17, 2025 01:20:59

- Click:0

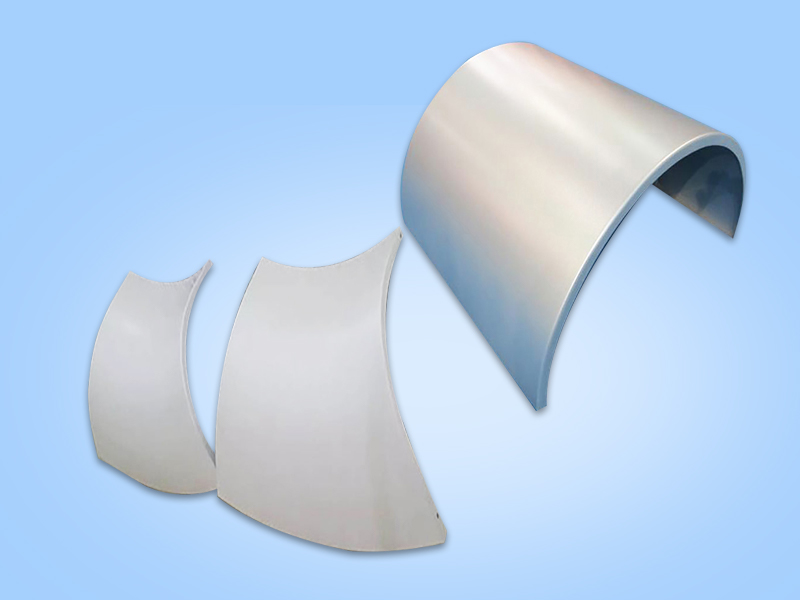

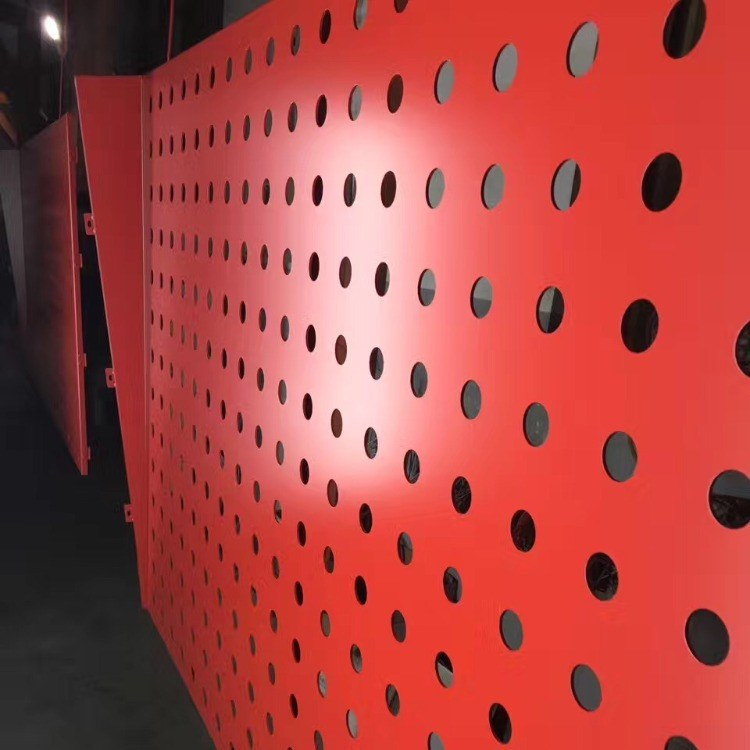

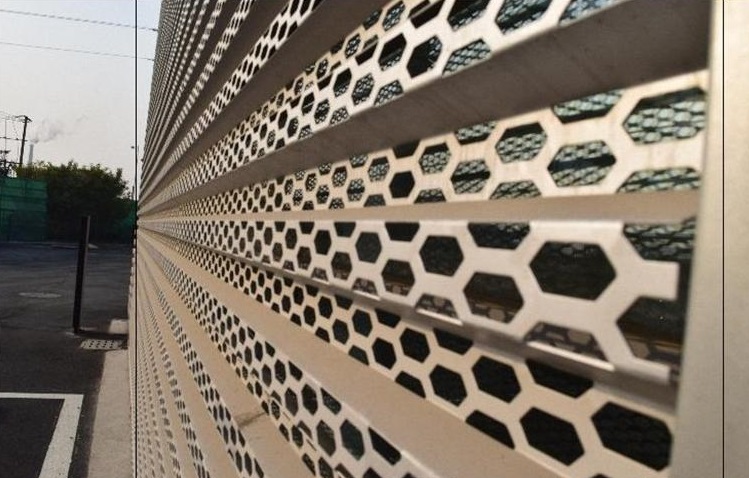

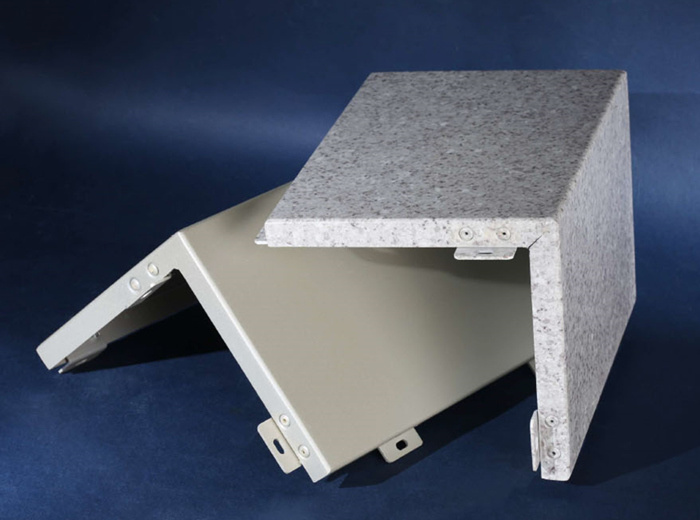

With the development of the architectural decoration industry, the thickness of 2.5mmAluminum veneerThe application is becoming increasingly widespread. In addition to conventional surface treatment methods, electrophoresis has also become one of the commonly used surface treatment methods. The electrophoretic process of 2.5mm thick aluminum veneer will be described in detail below.

1、 Principle of Electrophoretic Process

Electrophoretic technology is a physical and chemical surface treatment technique that uses current to move in an electrolyte to deposit thin films. In the electrophoresis process of 2.5mm thick aluminum veneer, it is necessary to first prepare an electrophoresis device with an electrophoresis tank and a power supply, and then install the device on the surface of the substrate. By energizing, a dense oxide film is formed on the surface of the aluminum veneer, ultimately achieving the desired decorative effect.

2、 Electrophoretic process flow

1. Prepare electrophoresis tank: Design and manufacture according to needs to ensure the quality and compatibility of electrophoresis tank specifications.

2. Cleaning the substrate: Use appropriate cleaning agents to clean the substrate to remove surface dirt and grease.

3. Install electrophoresis tank: Install the prepared electrophoresis tank on the surface of the substrate, ensuring that the position and direction are correct.

4. Add electrophoresis solution: Add the electrophoresis solution to the electrophoresis tank and adjust parameters such as conductivity and pH to achieve the desired deposition conditions.

5. Perform electrophoresis: After being powered on, place the aluminum veneer into an electrophoresis tank for electrophoresis treatment to deposit a layer of oxide film on its surface.

6. Follow up processing: Perform subsequent processing as needed, such as drying, to enhance the decorative effect.

3、 Precautions

When performing electrophoresis process on 2.5mm thick aluminum veneer, the following points should be noted:

1. It is necessary to choose and match according to actual needs and usage environment to ensure that the decorative effect meets the expected requirements.

2. When selecting materials and processing, attention should be paid to the matching of quality and specifications to avoid situations where problems cannot be solved.

3. During the construction process, it is necessary to pay attention to the implementation of safety protection measures to prevent accidental injury accidents.

4、 Summary

The electrophoretic process of 2.5mm thick aluminum veneer is one of the important factors affecting its application effect. During the electrophoresis process, it is necessary to pay attention to the preparation work, correct selection and matching of materials, and strict quality inspection to ensure that the product meets the expected requirements. At the same time, it can also be reasonably matched and used according to market demand and aesthetic standards to enhance the beauty and added value of the product.

- previous page:Market demand for 2.5mm thick aluminum veneer

- Next page:Polishing process of 2.5mm aluminum veneer

Customer service QQ

Customer service QQ