Industry information

Company News

- How much do you know about aluminum ceiling: a fashionable choice in modern architecture?

- The secret of aluminum honeycomb panel: as light as a feather, as solid as a rock!

- Honeycomb aluminum plate: the technological secret behind its lightweight design

- Aluminum curtain wall, the 'invisible hero' in modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space

Industry dynamics

- The secret behind aluminum ceiling: the perfect fusion of lightness and aesthetics

- Environmental characteristics and market demand of aluminum veneer

- Aluminum curtain wall: the aesthetic choice of modern architecture, revealing the story behind it

- Application scenarios of imitation stone patterned aluminum veneer

- The magical charm of honeycomb aluminum plate: the secret behind its lightness

Frequently asked questions

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer be used in the design of building arch bridges?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- How does the plasticity of aluminum veneer affect building comfort?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the technological power behind lightness

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: March 2, 2025 21:29:41

- Click:0

Ladies and gentlemen, today let's talk about a somewhat mysterious but super practical material - honeycomb aluminum plate. You may not have heard of it much, but it shines in many high-tech fields!

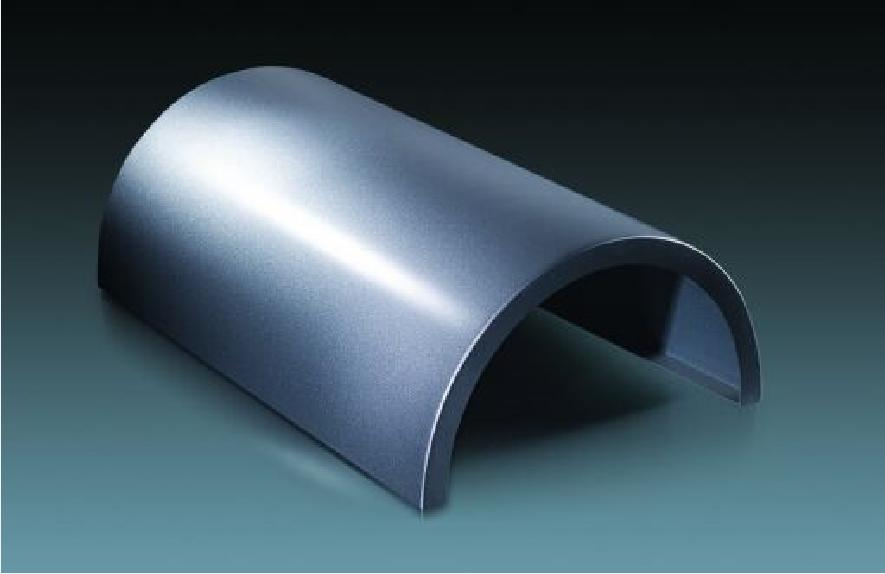

We need to understand what honeycomb aluminum plate is. It is like a honeycomb, composed of many small hexagonal honeycomb structures that are interconnected to form a sturdy and lightweight whole. This design ensures the strength of the material while greatly reducing its weight.

I first came into contact with honeycomb aluminum panels in a university laboratory. At that time, the professor showed us a model made of honeycomb aluminum plate, which had a peculiar shape but appeared exceptionally sturdy. I remember thinking at that time, how was this thing done?

The manufacturing process of honeycomb aluminum plate is actually quite complex. The aluminum plate needs to be cut into a certain size and then pressed into a honeycomb shape through a special mold. This process requires high precision, otherwise the honeycomb structure will be uneven, affecting the performance of the material. After production, surface treatment such as spraying or anodizing is required to improve its corrosion resistance and aesthetics.

The reason why honeycomb aluminum panels are popular is mainly because they have several excellent characteristics. It's light. How light is it? It is much lighter than ordinary aluminum plates, but its strength is not inferior. This is like a martial arts master, as light as a swallow, yet with infinite strength.

It is corrosion-resistant. Due to the surface treatment technology of honeycomb aluminum plate, it can resist various harsh environments such as acid, alkali, salt spray, etc. This makes it very useful in many outdoor application scenarios.

Let's talk about the strength of honeycomb aluminum sheet again. Its strength actually depends on the size and shape of the honeycomb structure. The smaller the honeycomb structure, the higher the strength of the material. This is like a person's muscles, the more developed they are, the stronger their strength.

Speaking of which, some people may ask, is such good material expensive? The price of honeycomb aluminum sheet is not high. With the continuous improvement of manufacturing technology, production costs are gradually decreasing. It has been widely used in aerospace, transportation, construction, electronics and other fields.

I remember one time when I visited an aerospace company and saw their aircraft parts made of honeycomb aluminum panels, I was amazed. The application of this material makes airplanes lighter, more efficient, and also improves safety.

In addition to aerospace, honeycomb aluminum panels are also widely used in the construction industry. Some high-end buildings use honeycomb aluminum panels on their roofs, exterior walls, etc. to enhance their aesthetics and durability. I heard that some famous architects really enjoy using this material.

Honeycomb aluminum panels also have their limitations. It is difficult to process and requires special equipment and techniques. Its price is still higher compared to ordinary aluminum plates.

Honeycomb aluminum plate is an excellent material. Its characteristics of lightness, corrosion resistance, and high strength make it have broad application prospects in many fields. Perhaps in the near future, we will see more high-tech products made from honeycomb aluminum sheets.

What I want to say is that the development of technology cannot be separated from innovation. Just like honeycomb aluminum sheet, its appearance is the crystallization of human intelligence. Let's look forward to more magical materials like honeycomb aluminum panels in the future, bringing more convenience and surprises to our lives!

Customer service QQ

Customer service QQ