Industry information

Company News

- Aluminum veneer: not just sheet metal, but also the soul of modern architecture

- Honeycomb aluminum plate: the secret of being as light as a feather and as solid as a rock

- Aluminum veneer: the "silver garment" of modern architecture

- New Chapter of Aluminum Curtain: Fashion and Power in Modern Architecture

- The Beauty of Aluminum Ceiling: The Glorious Transformation of Space Art

Industry dynamics

- Aluminum veneer on walls and exterior walls makes buildings safer and more aesthetically pleasing

- A new choice for building appearance created by fluorocarbon aluminum veneer ceiling

- Aluminum Curtain Wall: The 'Gorgeous Coat' of Modern Architecture

- Aluminum veneer, your new darling of modern architecture!

- Aluminum ceiling: an innovator in industrial aesthetics, taking you to appreciate the beauty of space

Frequently asked questions

- Can aluminum veneer achieve customized design?

- How can aluminum veneer improve the appearance of buildings?

- Can aluminum veneer be used in the design of building arch bridges?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Honeycomb aluminum plate: the secret behind its lightweight design

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: February 26, 2025 01:28:42

- Click:0

Dear readers, today let's talk about a material that sounds a bit high-end - honeycomb aluminum plate. You may ask, what is honeycomb aluminum plate? What's special about it? Don't worry, let's talk slowly.

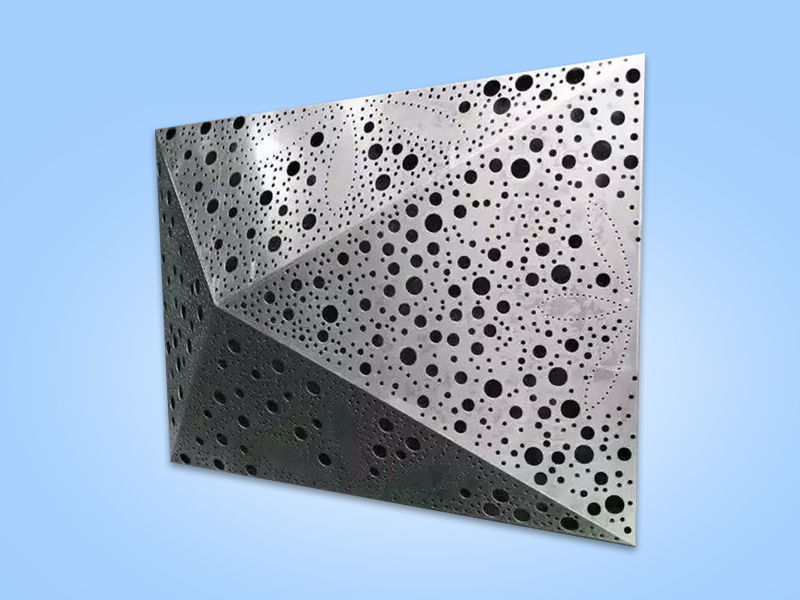

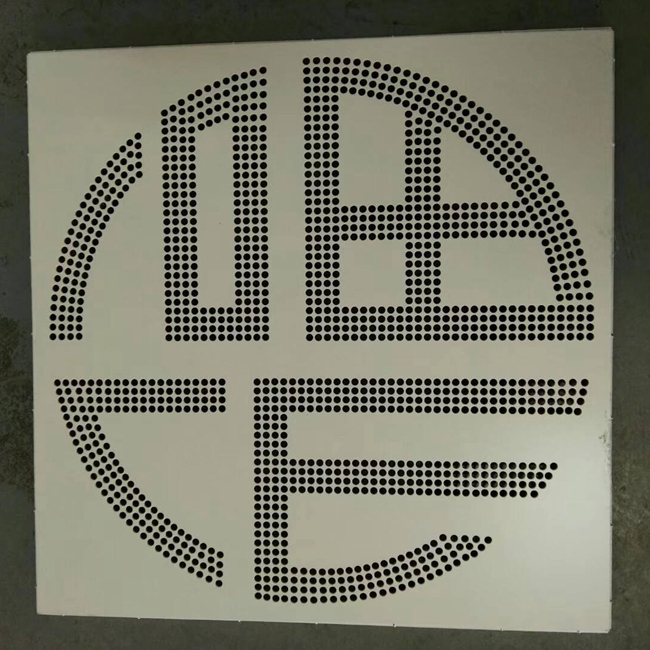

Let's talk about the origin of the name honeycomb aluminum plate. Imagine the appearance of bees building beehives, are they like small beehives? Honeycomb aluminum plate is inspired by this honeycomb structure and made of aluminum plate. This structure may sound simple, but it has many wonders.

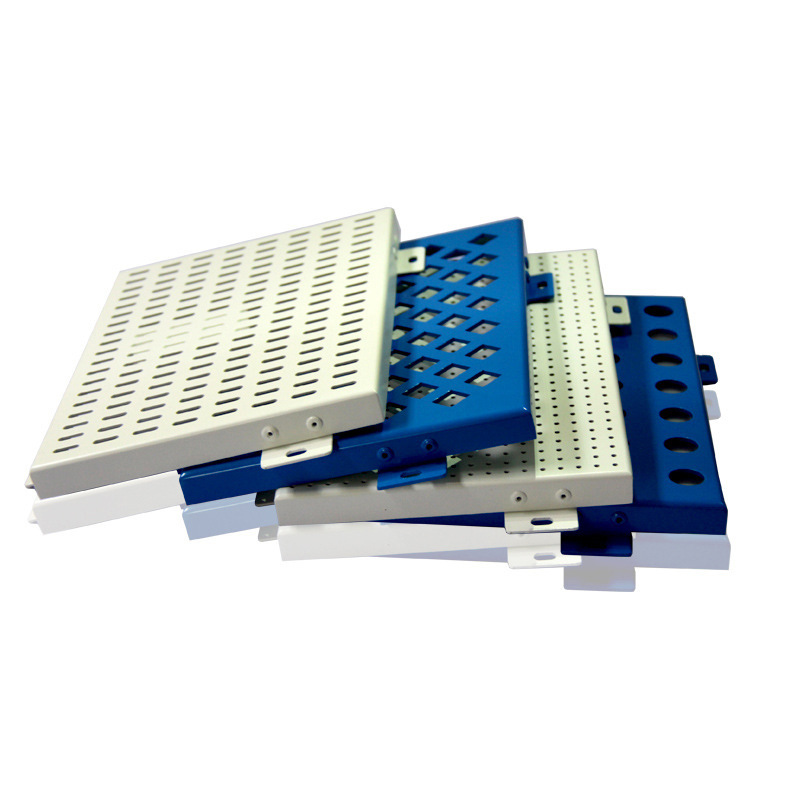

Honeycomb aluminum plate is very lightweight, weighing only about 1/10 of solid aluminum plate of the same volume. Imagine an airplane using honeycomb aluminum panels for its fuselage, how fuel-efficient it would be! Isn't this the power of technology? Lightweight does not mean fragile. Honeycomb aluminum panels have high strength and first-class seismic performance. When used in buildings, their safety is guaranteed.

Honeycomb aluminum panels not only excel in the aerospace industry, but are also highly favored in fields such as automotive manufacturing, electronic products, and building materials. I have a friend who said that the application of honeycomb aluminum panels in automobile manufacturing greatly reduces fuel consumption, is environmentally friendly, and energy-saving.

When it comes to environmental protection, honeycomb aluminum sheet has another advantage, which is its recyclability. This is the green environmental protection concept advocated by today's society. Unlike some materials that turn into garbage after one use, honeycomb aluminum panels can be reused, saving resources and reducing pollution.

However, honeycomb aluminum panels also have their drawbacks. For example, the cost is relatively high. After all, good things are never cheap. But considering its advantages, what are these small drawbacks?

The application scenarios of honeycomb aluminum panels are really diverse. I recently read a news that a sea crossing bridge in a certain area is made of honeycomb aluminum panels. This bridge is not only beautiful and elegant, but also safe and durable, truly making people marvel at the magic of technology.

Let's talk about electronic products again. Nowadays, many electronic products such as smartphones and tablets use honeycomb aluminum plates. This material can not only reduce the weight of the equipment, but also improve the signal reception effect. My own phone is made of honeycomb aluminum plate, and the signal is so good that it's hard to say.

Of course, the application areas of honeycomb aluminum panels are far beyond these. In building materials, honeycomb aluminum panels can be used to make roof panels, wall panels, etc., which are both beautiful and practical. Honeycomb aluminum panels also have good fire resistance, making them safer and more reassuring when used in buildings.

How is honeycomb aluminum plate made? Its production process is not complicated. Cut the aluminum plate into a certain size, and then process it into a honeycomb shape through special techniques. By splicing these honeycomb aluminum plates together, we obtain honeycomb aluminum plates.

The application prospects of honeycomb aluminum plate are broad, and it is believed that in the near future, it will play an important role in more fields. With the continuous development of technology, the production process of honeycomb aluminum panels will become more and more mature, and the cost will gradually decrease, benefiting more people.

What I want to say is that although honeycomb aluminum panels are good, we also need to approach them rationally. Everything has two sides, and we cannot ignore its disadvantages just because of its advantages. While enjoying the convenience brought by technology, we should also pay attention to environmental protection and resource conservation, making our lives better.

Honeycomb aluminum plate is a magical material that is lightweight, sturdy, environmentally friendly, and has broad application prospects. Let's look forward together, in the future, honeycomb aluminum panels can bring more surprises to our lives!

Customer service QQ

Customer service QQ