Industry information

Company News

- Aluminum veneer: easily upgrade the appearance of buildings

- The charm of honeycomb aluminum plate: the perfect combination of lightness and sturdiness

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer: the beauty of industry, simplicity is not simple

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Honeycomb aluminum plate: the secret behind its lightweight design

- Aluminum ceiling, creating a new trend of fashionable home furnishings

- Application fields and technical analysis of imitation wood grain aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum Veneer: Exploring the Charm of New Era Building Materials

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- Is the surface treatment of aluminum veneer durable?

- How can aluminum veneer improve the appearance of buildings?

- How does the service life of aluminum veneer compare to other exterior wall materials?

- Can the insulation function of aluminum veneer solve the structural problems of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The wonderful world of honeycomb aluminum plate: light as air, strong as iron!

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-17 22:53:23

- Click:0

Ladies and gentlemen, today let's talk about a magical material - honeycomb aluminum plate! Does this name sound a bit fancy? It is a common lightweight and high-strength material in daily life. Don't underestimate it, it's a great helper in fields such as architecture, aviation, and aerospace!

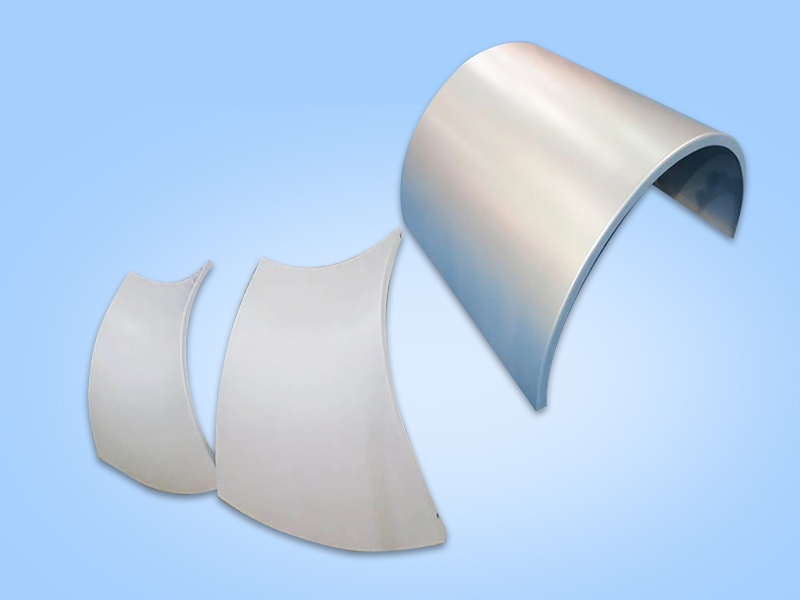

Honeycomb aluminum plate, as the name suggests, is an aluminum plate composed of a honeycomb structure. This structure gives honeycomb aluminum plates the characteristics of ultra light and high strength. You may be asking, why is honeycomb aluminum plate so light? This is thanks to its honeycomb like structure. Imagine a honeycomb, where each small cell is a triangle composed of six sides, making the honeycomb both stable and lightweight. Honeycomb aluminum plate is inspired by this principle, cutting the aluminum plate into a honeycomb shape to achieve lightweight.

Although honeycomb aluminum sheet is lightweight, its strength is not inferior to other materials at all. This is due to the advantage of the honeycomb structure. When the honeycomb aluminum plate is subjected to external forces, its internal structure can disperse and absorb some of the force, making the overall force more uniform. In this way, honeycomb aluminum plates can withstand greater loads while maintaining smaller deformations, making them as light as air and as strong as iron!

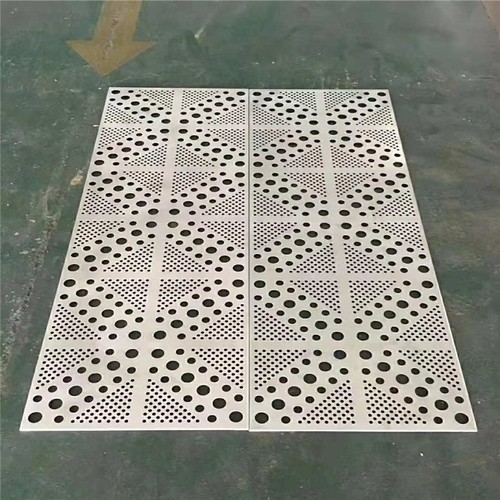

Let's first talk about the application of honeycomb aluminum panels in the field of construction. You know what? Nowadays, many high-end buildings use honeycomb aluminum panels as exterior wall decoration materials. Why? Because it is both beautiful and practical. Honeycomb aluminum plate has a smooth surface and rich colors, which can meet various design needs. It also has excellent insulation and thermal insulation performance, which can effectively reduce building energy consumption. Imagine walking into a building decorated with honeycomb aluminum panels, feeling particularly relaxed?

Let's talk about the application of honeycomb aluminum panels in the aviation industry. In the aerospace industry, honeycomb aluminum panels are a great place to showcase their skills. Honeycomb aluminum panels are commonly used for the shells, partitions, and other components of aircraft such as airplanes and rockets. Why? Because it's light! How light is it? A Boeing 737 aircraft, honeycomb aluminum panels account for about 20% of its weight. This type of material allows the aircraft to reduce its own weight while ensuring structural strength, which is truly a win-win situation!

The application of honeycomb aluminum sheet is far more than that. It plays an irreplaceable role in fields such as automobiles, ships, and medical equipment. The use of honeycomb aluminum panels on car bodies can reduce fuel consumption and improve fuel efficiency; The use of honeycomb aluminum panels on the deck of a ship can reduce its weight and increase its speed; Honeycomb aluminum plates in medical devices can provide comfortable support for patients.

How is honeycomb aluminum plate made? The process of making honeycomb aluminum sheet is not complicated. Cut the aluminum plate into sheets of a certain size, and then press them into a honeycomb structure through a special process. This process requires precise equipment and strict control to ensure the quality of honeycomb aluminum sheets.

I want to share a little story. Once, while browsing the building materials market, I saw a shop selling honeycomb aluminum panels. Curiosity drove me in to investigate. The shop owner told me that his honeycomb aluminum plate is imported and has guaranteed quality. I asked him, "Why are imported honeycomb aluminum panels better than domestic ones?" The shop owner smiled and said, "Domestic honeycomb aluminum panels are also good, but imported technology is more advanced and the quality is more stable." After listening to his words, I immediately developed a strong interest in honeycomb aluminum panels.

Honeycomb aluminum plate is a lightweight and high-strength magical material. It is widely used in various fields and has brought many conveniences to our lives. Perhaps in the near future, there will be more unexpected applications for honeycomb aluminum panels. Let's look forward to this magical honeycomb aluminum plate together, creating more beautiful futures for us!

Customer service QQ

Customer service QQ