Corporate News

Company News

- Aluminum veneer: creating a new style of modern architecture

- Aluminum curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating personalized space and new fashion

- Honeycomb aluminum plate: a secret weapon as light as a feather and as solid as a rock

- The secret of aluminum honeycomb panel: light as a feather, indestructible!

Industry dynamics

- Aluminum ceiling, the 'invisible guardian' of modern architecture

- Aluminum veneer customization, creating an exclusive personalized space

- What is the reflective performance of aluminum veneer?

- Application of hyperbolic aluminum veneer in urban buildings

- Aluminum honeycomb panel: the 'invisible hero' of the construction industry

Frequently asked questions

- Has the production process of aluminum veneer reduced energy consumption?

- How to evaluate the impact of environmental certification for aluminum veneer on the appearance of buildings?

- Is the surface treatment of aluminum veneer durable?

- Can aluminum veneer achieve customized design?

- How does the plasticity of aluminum veneer affect building comfort?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum honeycomb panel: the secret behind lightweight structure

- Author: Lesilong Technology (Guangdong) Co., Ltd

- Release time: 2022-03-08 20:01:05

- Click:0

hello everyone! Today, let's talk about a magical material - aluminum honeycomb panel. You may often see its presence on construction sites or high-end decorations, but do you know the story behind it? Let me take you through the mysterious veil of aluminum honeycomb panels.

We need to talk about the characteristics of aluminum honeycomb panels. This thing is lightweight, strong, waterproof, and heat-insulating, making it an all-around player in the building materials industry. But don't be fooled by its power, its birth is not simple.

We have to start from the 1950s, when the aviation industry was in a period of rapid development. Aircraft designers have started researching lightweight, high-strength materials in pursuit of faster speeds and higher altitudes. Aluminum honeycomb panels have emerged.

The structure of aluminum honeycomb panels is somewhat similar to a honeycomb, with a honeycomb like structure of aluminum in the middle and aluminum sheets wrapped around the outside. This structure enables aluminum honeycomb panels to be lightweight while also possessing high strength. Don't believe me? Let's calculate an account.

For example, a 1mm thick aluminum honeycomb panel may have a load-bearing capacity equivalent to several centimeters thick solid aluminum panels. That's why aluminum honeycomb panels are widely used in fields such as construction and aerospace.

How is aluminum honeycomb panel made? Press the aluminum plate into a honeycomb structure, and then weld the aluminum plate to the honeycomb structure. It sounds simple, but in practice it requires exquisite craftsmanship and equipment.

During the production process, attention should also be paid to controlling parameters such as size, thickness, and strength of aluminum honeycomb panels. This is the only way to ensure product quality. Although aluminum honeycomb panels may seem ordinary, they embody the wisdom of countless researchers behind them.

Besides in the fields of construction and aerospace, aluminum honeycomb panels have many other applications. We can see its presence on high-speed trains, cars, ships, and even in some high-end electronic products.

Why is aluminum honeycomb panel so popular? I think there are several main reasons:

1. Lightweight: Aluminum honeycomb panels have a light weight, making them easy to transport and install.

2. High strength: Aluminum honeycomb panels are lightweight and have high strength, capable of withstanding significant pressure.

3. Waterproof and Thermal Insulation: Aluminum honeycomb panels have excellent waterproof and thermal insulation properties, suitable for various harsh environments.

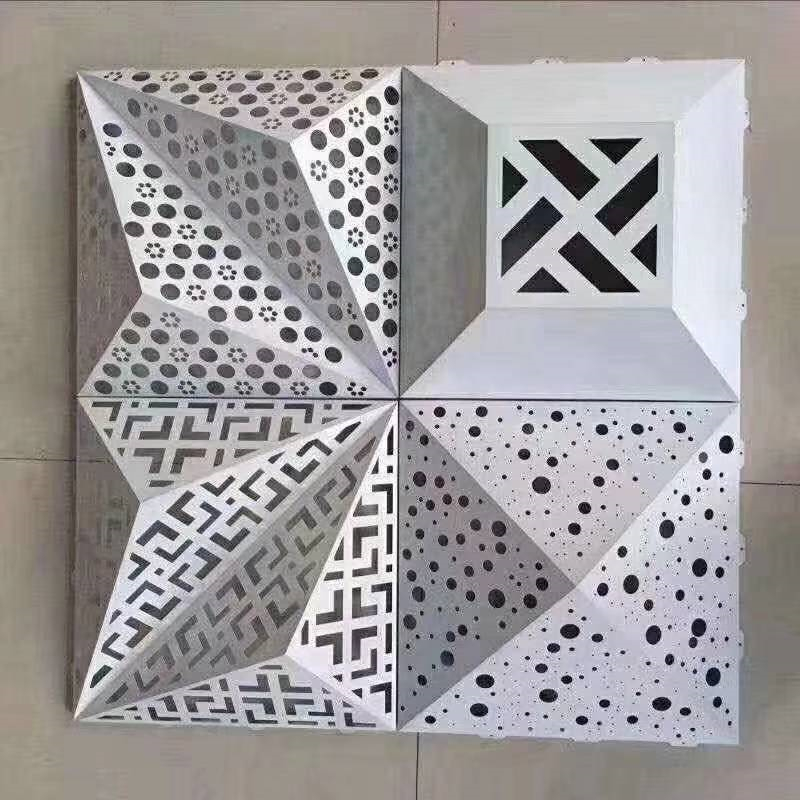

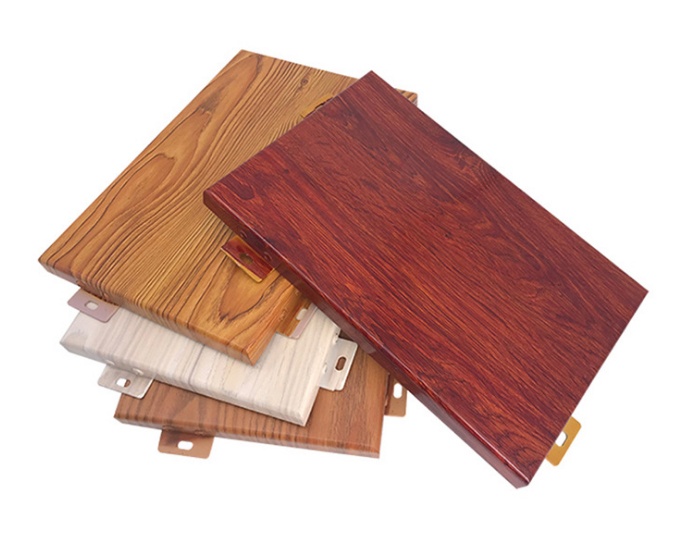

4. Aesthetics: Aluminum honeycomb panels have a smooth surface, diverse colors, and good decorative effects.

5. Strong processability: Aluminum honeycomb panels can be cut, bent, and processed according to requirements to meet different applications.

Aluminum honeycomb panels also have their drawbacks. High cost and difficulty in recycling and processing. But in today's constantly developing technology, these problems are gradually being solved.

Speaking of my personal experience, once I visited a skyscraper under construction and found that the exterior of the building was actually made of aluminum honeycomb panels. I am amazed by its beauty and uniqueness, and also feel the shock brought by technological progress.

Aluminum honeycomb panel is a magical material that shows us the power of technology. In this era full of challenges and opportunities, we believe that aluminum honeycomb panels will have broader application prospects.

I have a question for everyone: What other potential application scenarios do you think aluminum honeycomb panels will have in the future construction and industrial fields? Welcome to leave a comment in the comment section, let's discuss together!

Customer service QQ

Customer service QQ